An electromagnetic pulse radial powder compaction device and compaction method

A technology of electromagnetic pulse and compaction device, applied in the field of powder forming, can solve the problem of difficult to take out the core column, and achieve the effects of short pressing time, large discharge energy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The device of the present invention will be further illustrated and described below in conjunction with the drawings in the embodiments of the present invention.

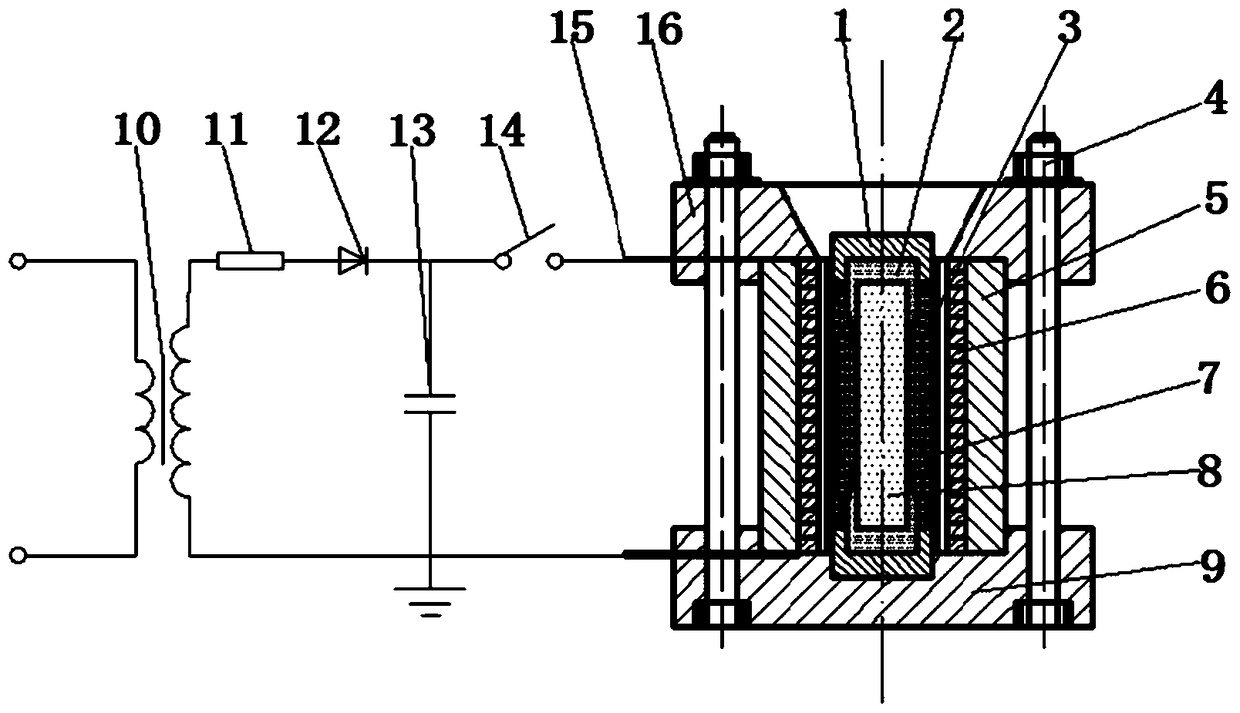

[0032] Depend on figure 1 Shown, device of the present invention is made up of power supply device, fixing device and compacting device.

[0033] The power supply device consists of a high-voltage transformer 10, a charging resistor 11, a charging circuit composed of a high-voltage rectifier 12, and a pulse discharge circuit composed of a capacitor bank 13. The high-voltage switch 14 is used to complete charging preparation and pulse discharge control during the entire forming process.

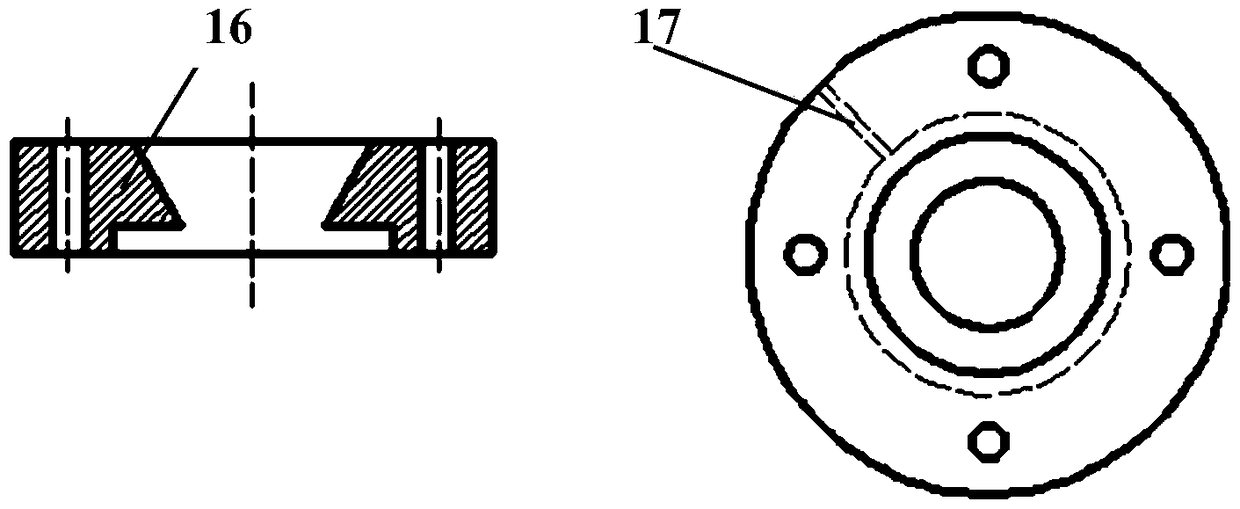

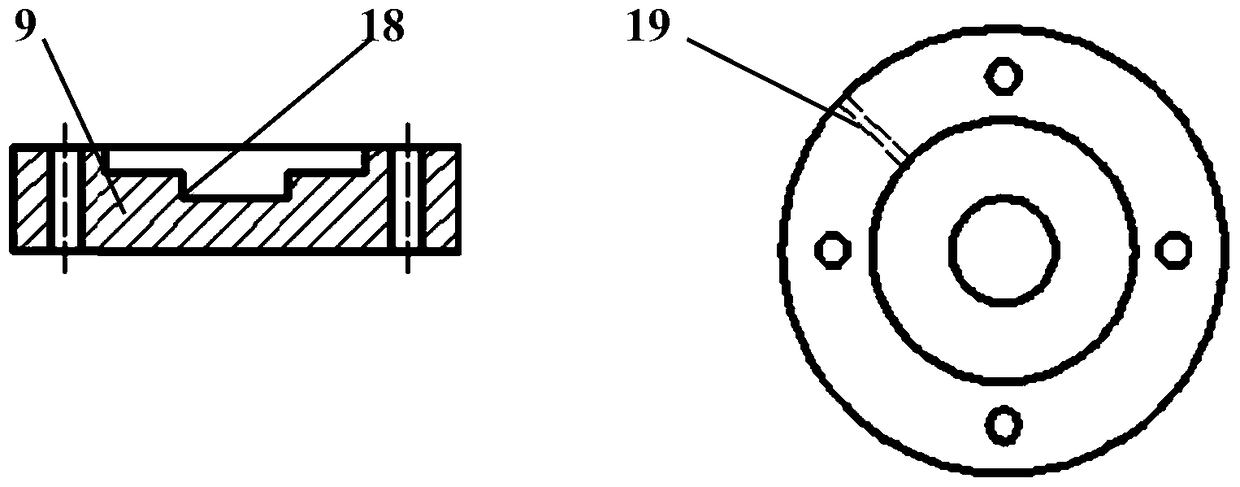

[0034] The fixing device is composed of a base 9, an end cover 16, an insulating protective cover 5, and a fixing bolt 4. It positions and fixes the compacting device, wraps the compacting device, and isolates high-voltage pulse discharge.

[0035] Insert the insulating protective cover 5 into the positioning groove 18 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com