Self-oscillation gas jet auxiliary atomization device

A technology of atomization device and gas jet, applied in the direction of injection device, injection device, etc., can solve problems such as increased viscosity of propellant, complex nozzle structure, high viscosity, etc., to improve combustion efficiency and specific impulse, improve atomization effect, The effect of accelerated cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

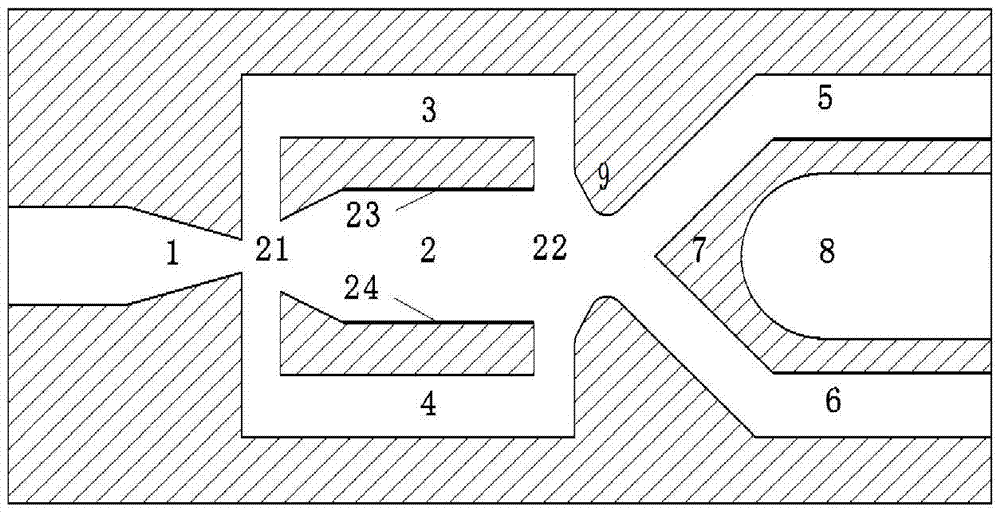

[0022] A self-excited oscillating gas jet assisted atomization device: the device is provided with a connected inlet, an oscillating chamber, a feedback loop, a gas nozzle, and an independently arranged liquid nozzle; wherein the inlet is connected to the oscillating chamber, and the outlet of the oscillating chamber is connected to the The gas nozzle is provided with several feedback loops near the outlet of the vibration chamber and is connected back to the inlet of the vibration chamber; the liquid nozzle is structurally independent from the above four parts, and is used to generate a liquid jet, which is atomized under the action of the oscillating air flow.

[0023] Specifically, such as figure 1 As shown, the shape of the entrance 1 of the device is contracted toward the direction of the oscillation cavity, and the oscillation cavity 2 is a cuboid cavity that gradually widens from the entrance to the exit. Exit bump 9. Protrusions can be arranged above and below the out...

Embodiment 2

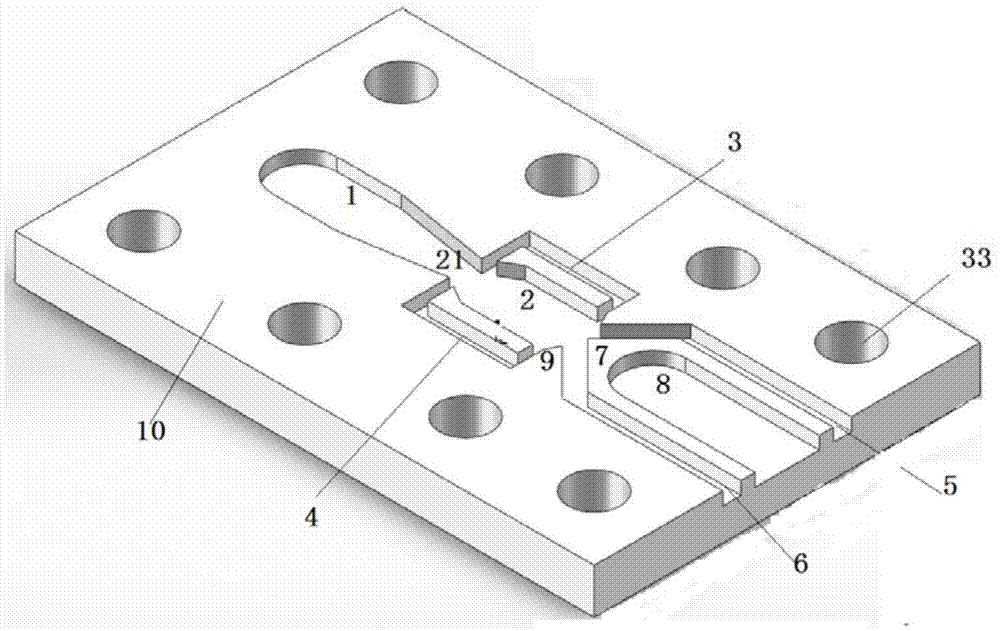

[0033] A self-excited oscillating gas jet assisted atomization device, mainly comprising a main board and a cover plate sealed and closed to the main board. The main board is specifically provided with an inlet, an oscillation chamber, a feedback loop, a gas nozzle, and a liquid nozzle as described in Embodiment 1.

[0034] like figure 2As shown, the main board 10 is provided with: the inlet 1 is connected to the oscillating chamber 2, the oscillating chamber 2 is connected to the gas nozzles 5 and 6, and there are two feedback loops 3 and 4 connected to the inlet 21 of the oscillating chamber near the outlet of the oscillating chamber; the liquid nozzle 8 is structurally independent from the above four parts.

[0035] like image 3 As shown, a gas pipe joint 11 is provided on the cover plate 20 at a position corresponding to the inlet, and a liquid pipe joint 12 is provided at a position corresponding to the liquid nozzle.

[0036] The main board and the cover board are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com