Sludge-dispersing equipment used for cement kiln for denitration

A sludge dispersion and cement kiln technology, applied in separation methods, dispersed particle separation, gas treatment, etc., can solve the limited effect of nitrogen oxide emission concentration, poor denitrification effect of dried sludge, and difficult flue gas contact Uniformity and other issues, to achieve the effect of saving ammonia water consumption, reducing ammonia water procurement costs, and speeding up the burnout speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

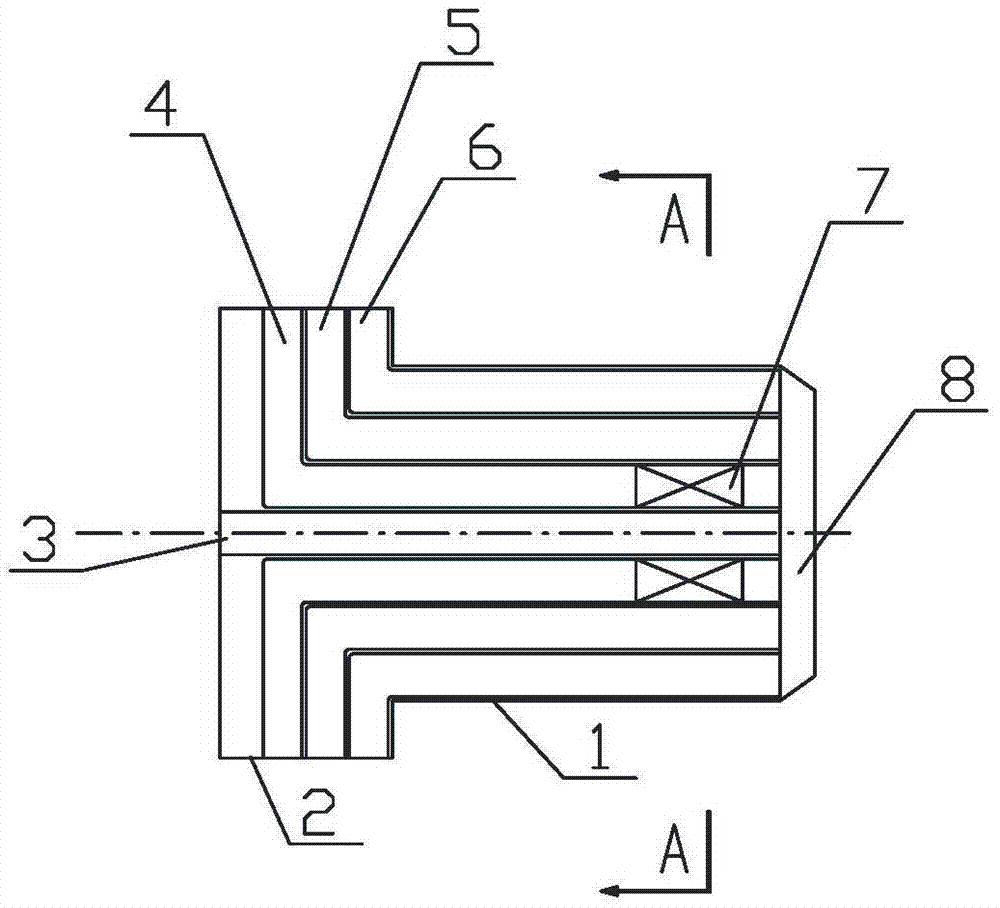

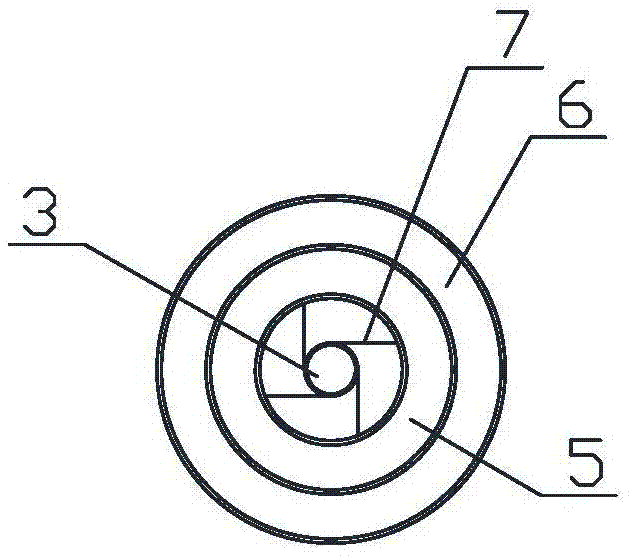

[0017] See Figure 1 ~ Figure 2 , a kind of sludge dispersing equipment for cement kiln denitrification, including a body 1, one end of the body 1 is an input end, and the other end is an output end; a central wind channel is sequentially formed in the body 1 from the inside to the outside 3. Swirling wind passage 4, dried sludge conveying passage 5 and axial flow wind passage 6; the central wind passage 3 extends along the central axis of the body 1; the swirling wind passage 4 is formed on the central wind An annular channel around the channel 3; the dried sludge conveying channel 5 is an annular channel formed around the swirling air channel 4; the axial flow air channel 6 is formed around the dried sludge conveying channel 5 The input en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com