Bearing device and method for rapid division of patterned sapphire substrate (PSS) chip

A technology for carrying devices and wafers, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unseen related reports, and achieve the effect of easy control and operation and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

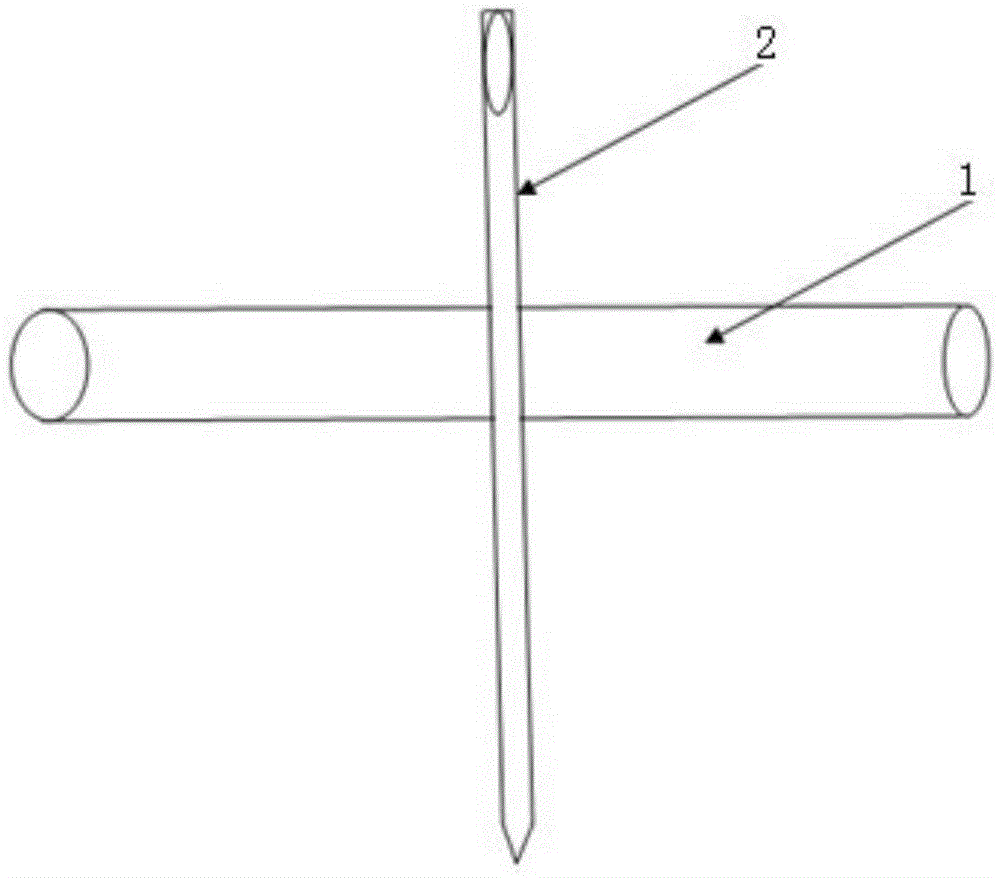

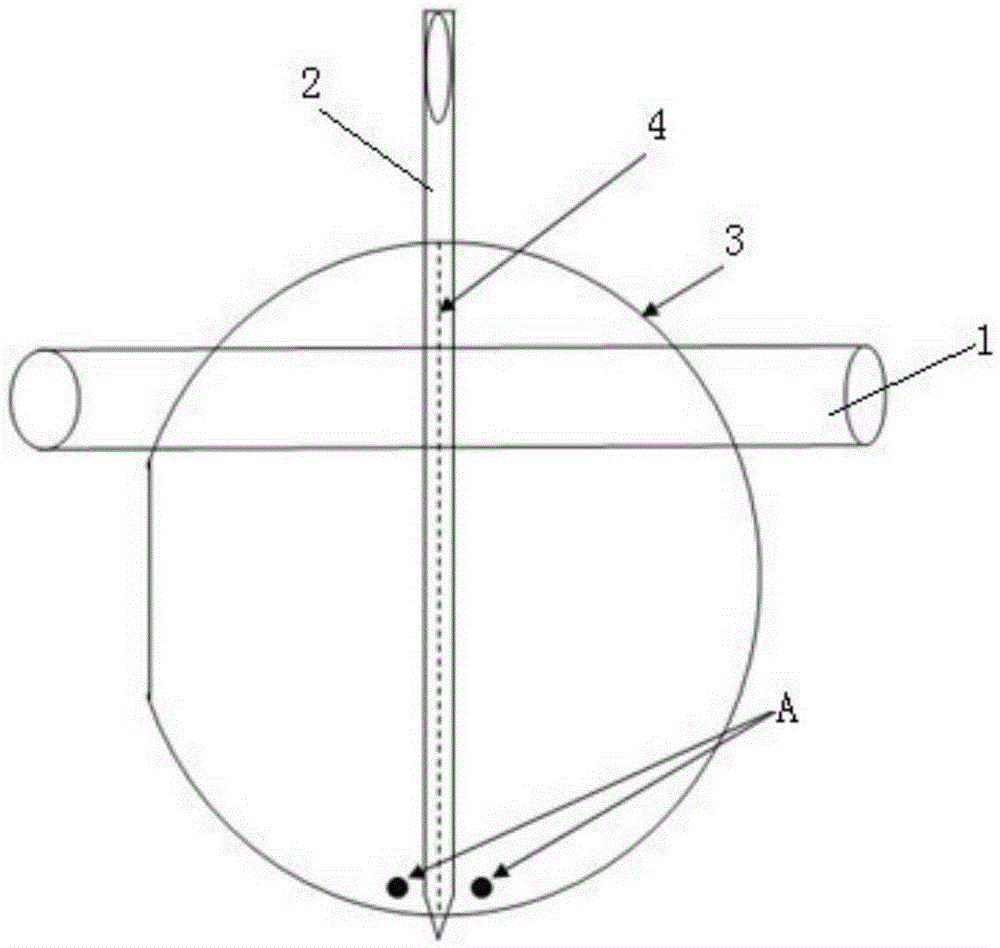

[0027] The carrying device of the present invention is made by taking a plastic rod 1 with a diameter of 5 mm and a length of 50-100 mm; taking a sewing needle 2 with a length of 50-80 mm; using the needle point of the sewing needle in the middle of the plastic rod 1 and insert the sewing needle 2 into the plastic rod 1, which can move up and down as required. The present invention is used as the carrying device of the PSS substrate wafer 3. During the split sample preparation process, a diamond knife is used Draw a knife scratch 4 along the line to be cracked on the back of the wafer, and then place the wafer to be cracked face up on the carrier, so that the diamond knife scratch and the sewing needle are in the same longitudinal and vertical direction. Mouth, press firmly with tweezers figure 2 The force point A of the lobes in the chip can split the wafer along the scratch of the diamond knife, which is convenient and fast.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com