Test device for applying axial tensile load to concrete members

A technology of axial tension and test equipment, applied in the direction of applying stable tension/pressure to test material strength, material inspection products, etc., to achieve the effect of easy control of load size, simple operation, and avoiding fracture and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

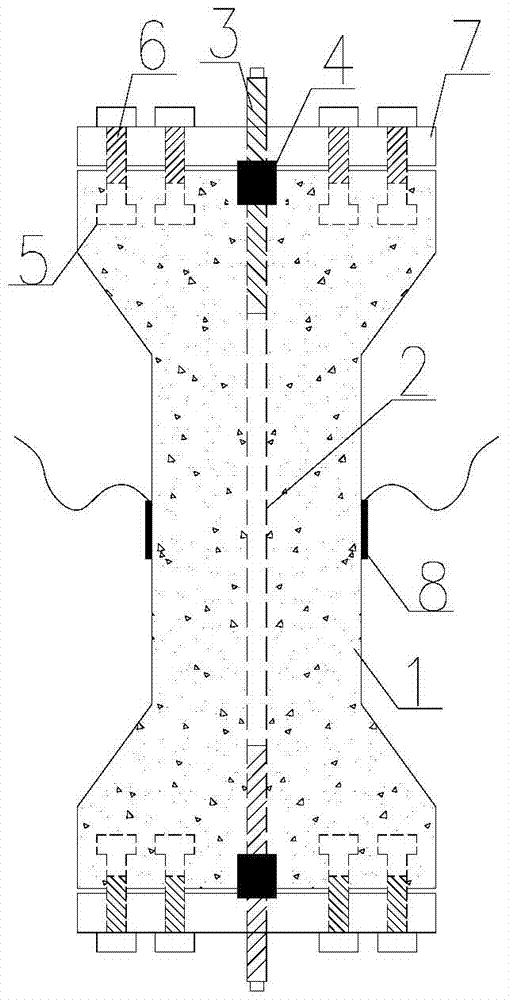

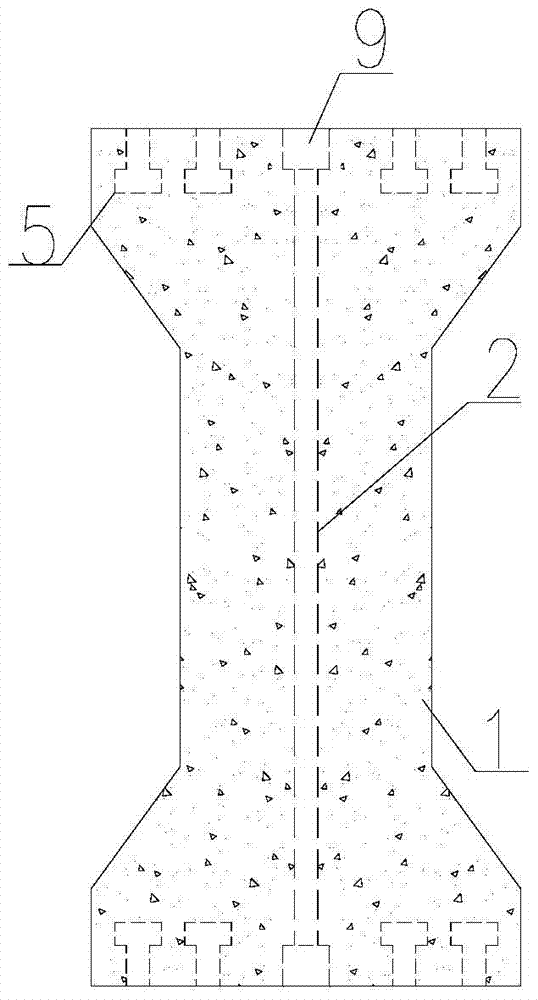

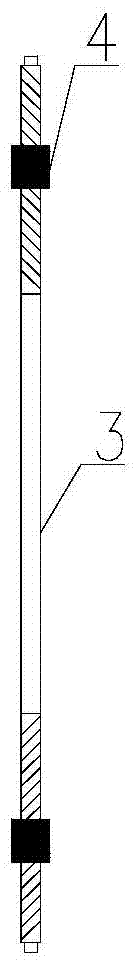

[0028] Embodiment 1 A test device for applying an axial tensile load to a concrete member according to the present invention, comprising a concrete axial tensile test piece 1, a load-bearing steel plate 7 mounted on both ends of the concrete axial tensile test piece, and a T-shaped embedded part with internal threads 5. Loading the screw rod 3 and the strain gauge 8, the concrete axial tension test piece 1 is provided with reserved through holes 2 arranged in the axial direction, and the two ends of the concrete axial tension test piece 1 are respectively embedded with multiple T-shaped Embedded part 5, and the threaded section of the T-shaped embedded part 5 points to the outside of the concrete axial tension test piece 1; the bearing screw 3 runs through the reserved through hole 2, and is arranged at both ends of the bearing screw 3 Nut 4, the outer side of the nut 4 is equipped with a load-bearing steel plate 7, and the threaded section of the T-shaped embedded part 5 is sc...

Embodiment 2

[0037] Embodiment 2 With measuring water-cement ratio 0.53 below, mixing ratio is cement: water: sand: the concrete of coarse aggregate=1:0.53:2.0:3.0 is example under the axial tensile load action chlorine salt transmission process, to the present invention The work is described in detail.

[0038]The raw materials for mixing concrete in this embodiment are: the cement is P.I 525 grade Portland cement, the sand is river sand with a fineness modulus of 2.6, the coarse aggregate is continuously graded crushed stone (maximum particle size 25mm), and the water is Tap water. The effective section size of the shaft-pulled concrete specimen is 100mm × 100mm, the flange protrusion length is 50mm, the flange edge height is 100mm, and the specimen length is 1000mm. For the embedded part, a reserved through hole 2 with a diameter of 26mm is reserved in the center of the test piece. After pouring and forming, the standard curing in the curing room is 28d, and the number of test pieces i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com