Fatigue testing machine for sugarcane detrashing machine detrashing element

A technology of a fatigue testing machine and a leaf peeler, applied in the field of fatigue testing machines, can solve the problems of complex operation, low measurement accuracy, and small proportion of mechanical and electronic parts, and achieves a controllable rotational speed, accurate measurement data, and controllable staggered depth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

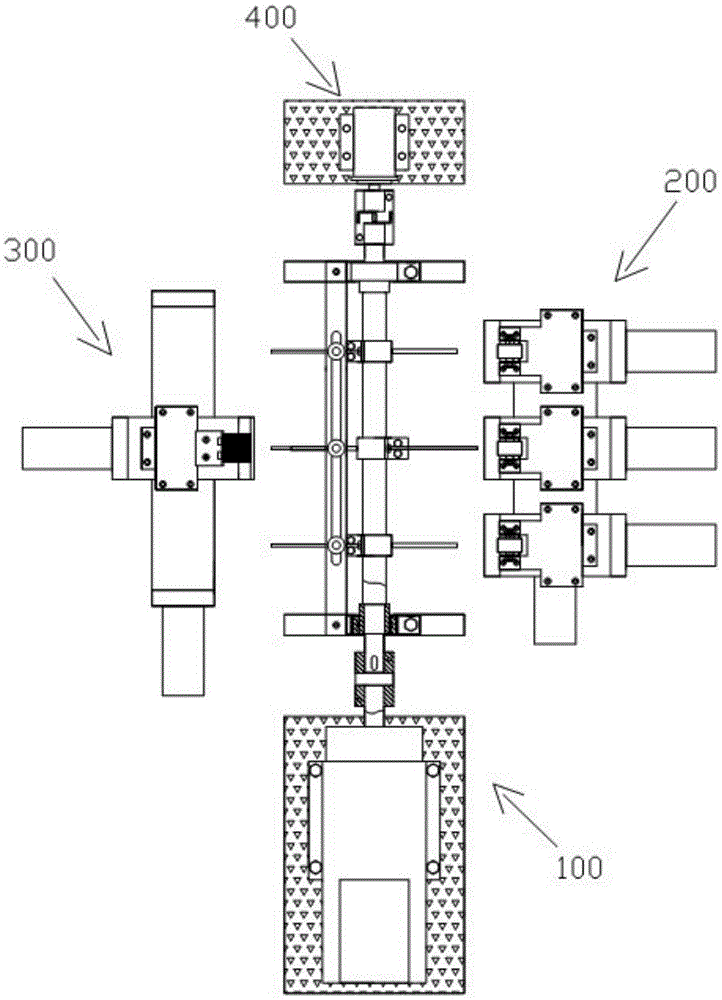

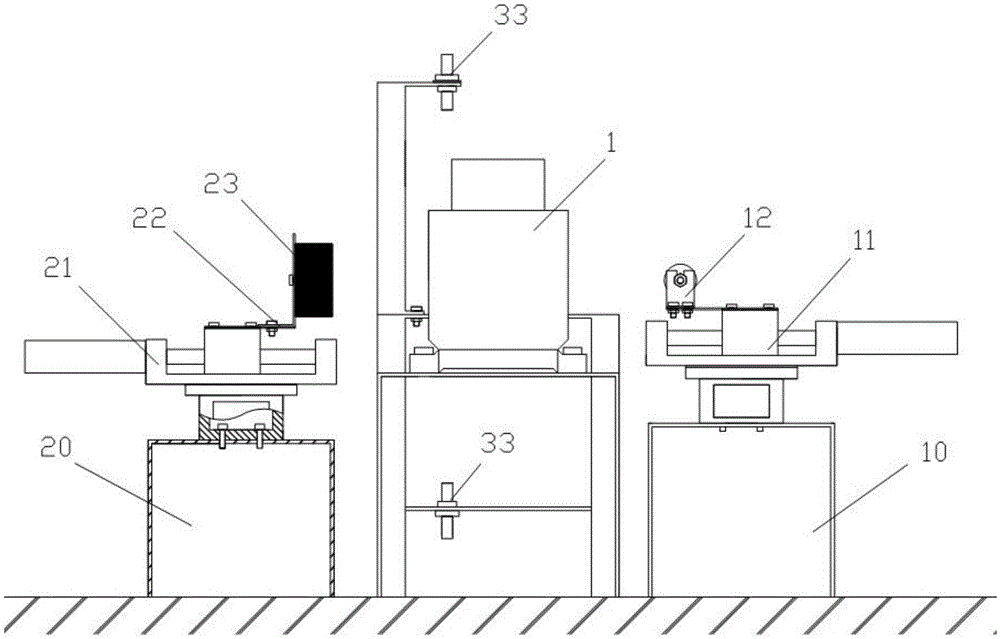

[0033] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

[0034] The invention discloses a fatigue testing machine, the testing machine is mainly used for detecting leaf stripping elements of sugarcane leaf strippers, and the striking force and fatigue life data of leaf stripping element samples at different rotating speeds and different staggered depths are obtained through tests, and through experiments Data, to obtain the relationship between the factors that affect the material fatigue performance of the sample (fatigue life, staggered depth, rotational speed and impact force, etc.), and provide data basis for the fatigue characteristics of the sample.

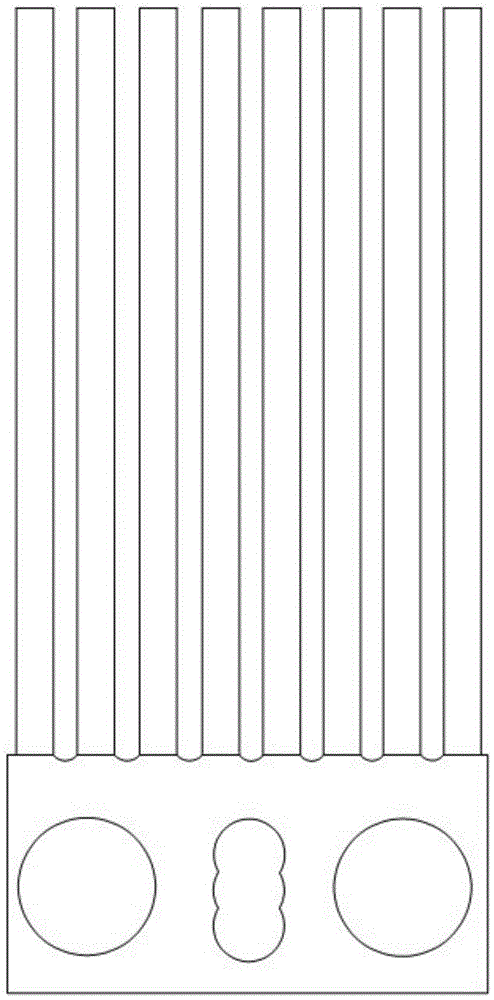

[0035] refer to figure 1 , The stripping element of the sugarcane leaf stripper is made of rubber as a whole, the front end is plate-shaped, and there are multiple rubber strips side by side at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com