Transverse wave couplant for power station boiler steel pipe inner wall oxide-film high frequency ultrasonic measurement, and preparation method thereof

A high-frequency ultrasonic, steel pipe inner wall technology, used in the use of ultrasonic/sonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. Shear wave coupling agent and other problems, to achieve the effect of large market value and application prospects, low cost, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

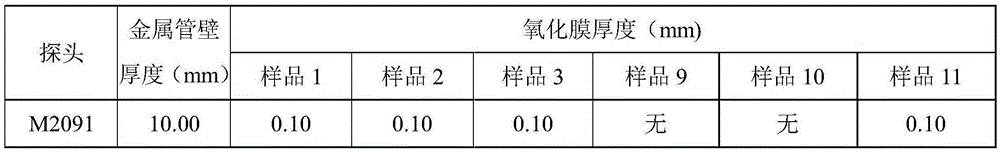

Image

Examples

Embodiment 1

[0056] The coupling agent is prepared according to the following mass percentages: honey 10%, starch 10%, and the balance fructose.

[0057] Preparation method: Weigh 80g of fructose, 10g of starch and 10g of honey, mix them, place in a beaker, heat at 95°C and fully stir for 20min, cool to room temperature, and obtain an amber paste, which is the coupling agent provided by the present invention.

Embodiment 2

[0059] The coupling agent is prepared according to the following mass percentages: 30% of honey and the balance of glucose.

[0060] Preparation method: Weigh 70g of glucose and 30g of honey, mix them, place in a beaker, heat at 80°C and fully stir for 15min, cool to room temperature, and obtain an amber paste, which is the coupling agent provided by the present invention.

Embodiment 3

[0062] The coupling agent is prepared according to the following mass percentages: 40% honey, 5% maltose, and the balance being lactose.

[0063] Preparation method: Weigh 55g of lactose, 5g of maltose and 40g of honey, mix them, place in a beaker, heat at 90°C and fully stir for 25min, cool to room temperature, and obtain an amber paste, which is the coupling agent provided by the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com