Integrated membrane bridge igniter and preparation method thereof

A thin-film bridge and thin-film technology, which is applied in the field of integrated thin-film bridge igniter and its preparation, can solve problems such as low consistency, poor reliability, and difficult packaging, so as to improve reliability and safety, reduce ignition energy, save The effect of debonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

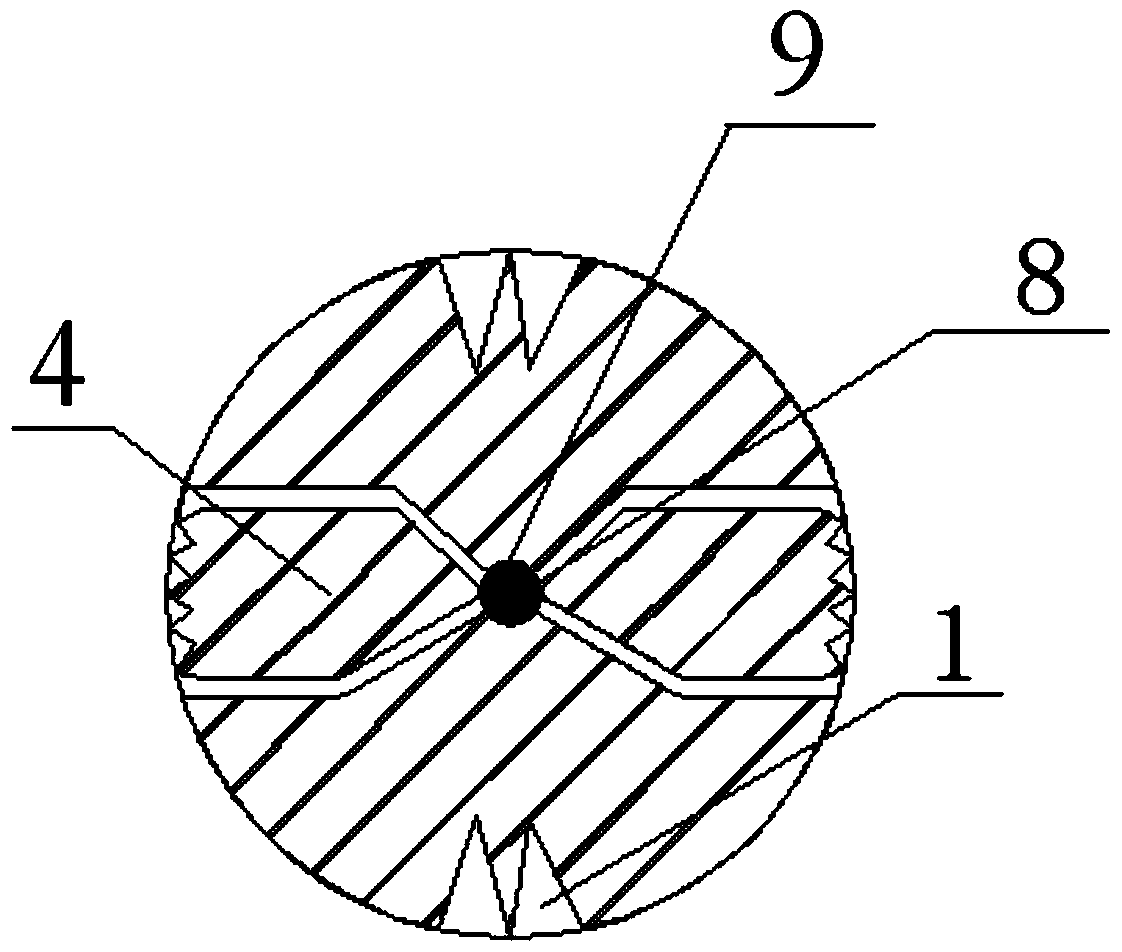

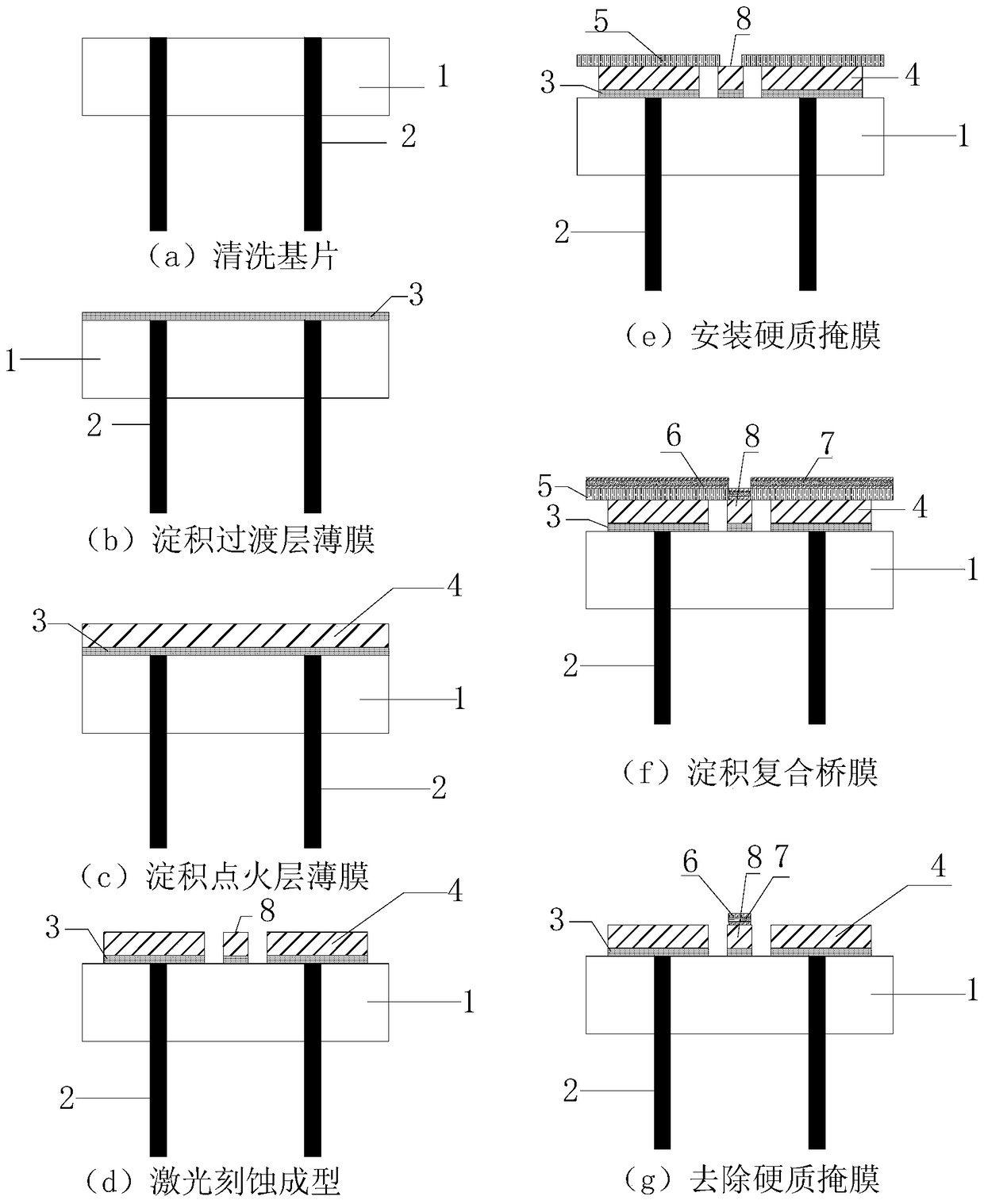

[0035] A kind of integrated membrane bridge igniter of the present invention, as figure 1As shown, the integrated thin film bridge igniter includes a base integral element 1 , a transition layer thin film 3 , an ignition layer thin film 4 and a composite bridge thin film layer 9 from bottom to top.

[0036] In this embodiment, the overall element 1 of the base body is a Φ8mm×20mm ceramic plug, and the ceramic plug is polished 99 porcelain (the upper surface is polished), and there are two Kovar alloy pole needles of Φ1mm inside the ceramic plug, and the pole needles 2 are exposed from the plug body The length is 15mm.

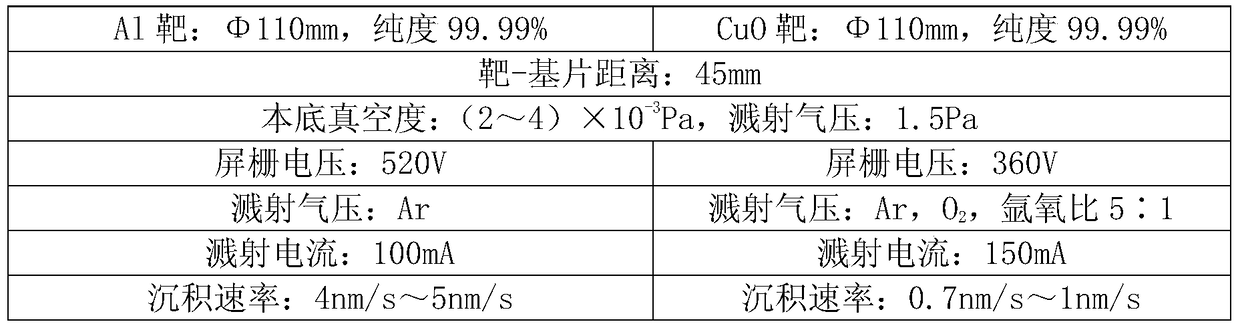

[0037] In this embodiment, the ignition layer film 4 is provided with a zigzag film bridge region 8 . The film material used for the ignition layer film 4 is NiCr (or TaN), with a thickness of 3.3 μm. In order to prevent static electricity and ensure safe ignition, the ignition layer film 4 is also provided with sawtooth structures up, down, left, and right. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com