A flip-chip blue-white light digital tube and a production method thereof

A production method and technology of digital tubes, applied in the direction of identification devices, instruments, electrical components, etc., can solve the problems of low consistency of light output, inconsistent thickness of colloid, uneven light output, etc., so as to increase the straight-through rate of good products and reduce the welding process , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

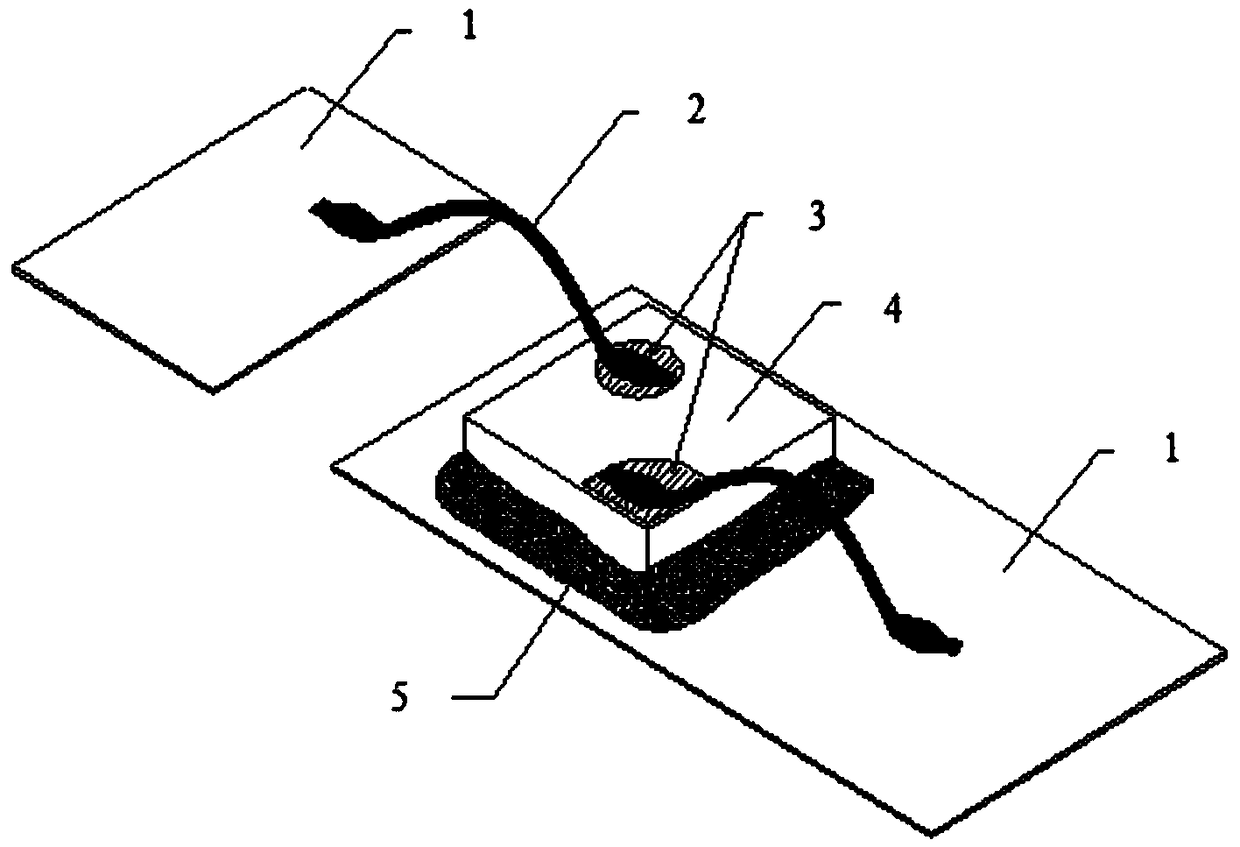

[0019] see figure 1 , the existing blue and white light digital tube is produced with common blue light chip 4, and the electrode 3 of this chip is on the chip surface, is fixed with insulating glue 5 during production, and welding lead 2 is connected with PCB 1 on the electrode 3.

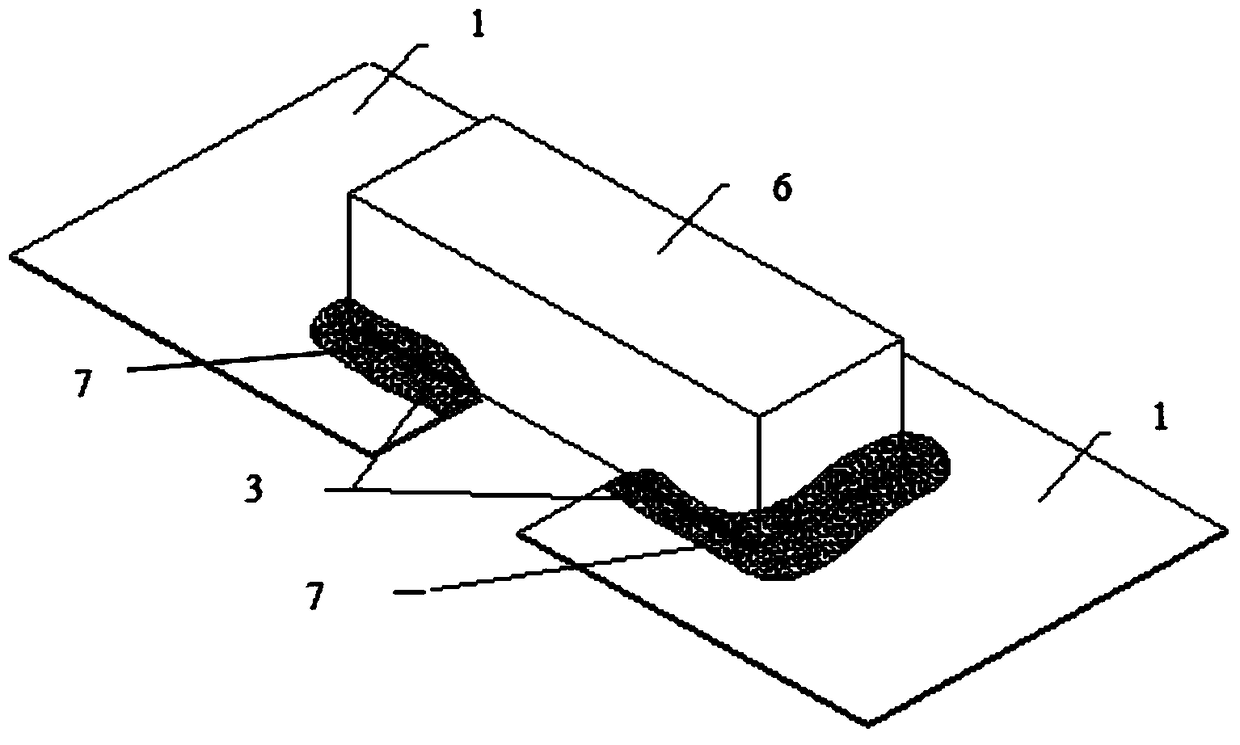

[0020] see figure 2 , the invention discloses a flip-chip blue-white light digital tube, comprising a PCB 1 and a flip-chip blue-ray chip 6, two solder pads are arranged on the PCB, solder paste 7 is arranged on the solder pads, and a bottom of the flip-chip blue-ray chip 6 is provided with Two electrodes 3, the electrodes are fixed by contacting with solder paste.

[0021] Wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com