Controller with integrated diversion line bank

A terminal block and controller technology, applied in the direction of conductive connection, connection, cooling/ventilation/heating transformation, etc., can solve the problems of affecting product quality, many welding processes, poor heat conduction effect, etc., saving installation time and improving product quality , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

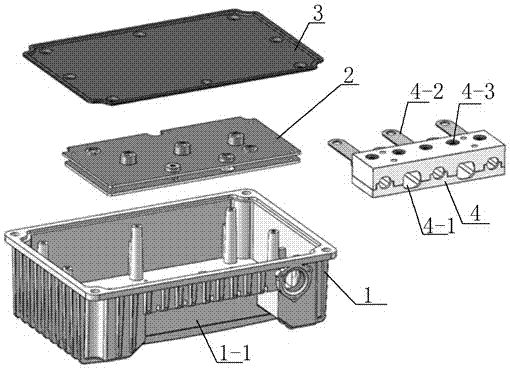

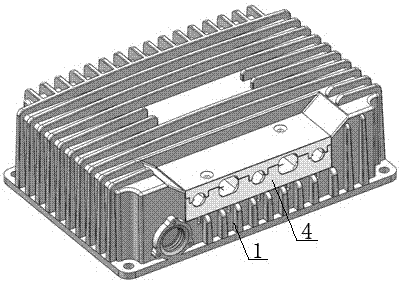

[0011] as attached figure 1 As shown, a controller with an integrated flow guide terminal block includes a controller die-casting heat dissipation aluminum shell 1, a power and function combination PCB board 2, a sealed back cover 3, and an injection molded integrated flow guide terminal block 4; the die-cast heat dissipation aluminum One side of the top surface of the shell 1 is provided with a terminal block embedded slot 1-1, and the side is provided with a data line outlet slot; the power and function combination PCB board 2 is provided with a power supply and a motor terminal, and the power and function combination PCB board 2 is installed in the die-casting heat-dissipating aluminum shell 1 through bolts; the injection-molded integrated current-guiding terminal block 4 is embedded in the embedded groove of the terminal block and fixed by bolts to lead out the power line and motor line; the sealed rear cover 3 is sealed and connected with the die-casting heat dissipation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com