Compound parabolic solar concentration type molten salt steam generator

A technology of steam generator and compound paraboloid, which is applied in the steam generation method using solar energy, steam generation, solar thermal power generation, etc. It can solve the problems that do not involve integration, etc., and achieve the effect of compact structure, cost reduction and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

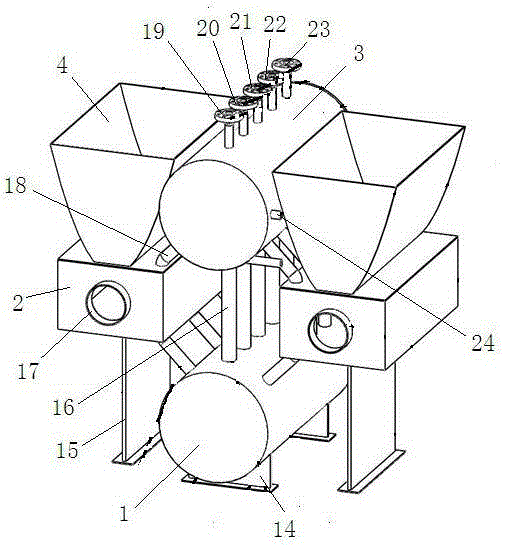

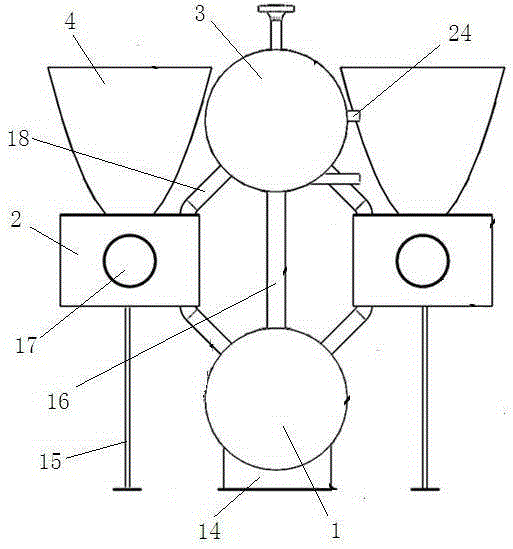

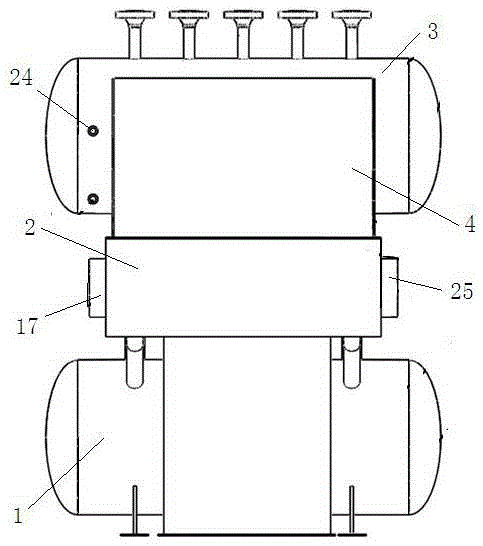

[0026] refer to Figure 1 to Figure 7 , a compound parabolic solar concentrating molten salt steam generator provided by the present invention includes a solar reflection device and a steam generator. In the steam generator, a lower drum 1 and an upper drum 3 are arranged below the upper drum 3 They are placed horizontally with the lower drum 1 respectively, their axes are parallel and located on the same vertical plane, molten salt tanks 2 are arranged symmetrically on both sides of the upper drum 3, and there are solar reflectors on the molten salt tank 2 on each side. The reflected sunlight focuses on the compound parabolic reflector 4 of the molten salt tank 2; the upper drum 3 is connected with a steam outlet 21, a pressure port 23, a temperature port 22, a safety valve port 20 and a water supply pipe port 19, one side It is connected with a liquid level gauge interface 24, and each side is respectively connected with an ascending pipe 18 and a heat pipe 31, wherein the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com