High-power LED lamp integrated cooling shell

A heat dissipation shell and LED lamp technology, which is applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problems of increased product weight, unfavorable wiring, and difficult molding, etc., to achieve Reduce product weight, avoid warping phenomenon, simple and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

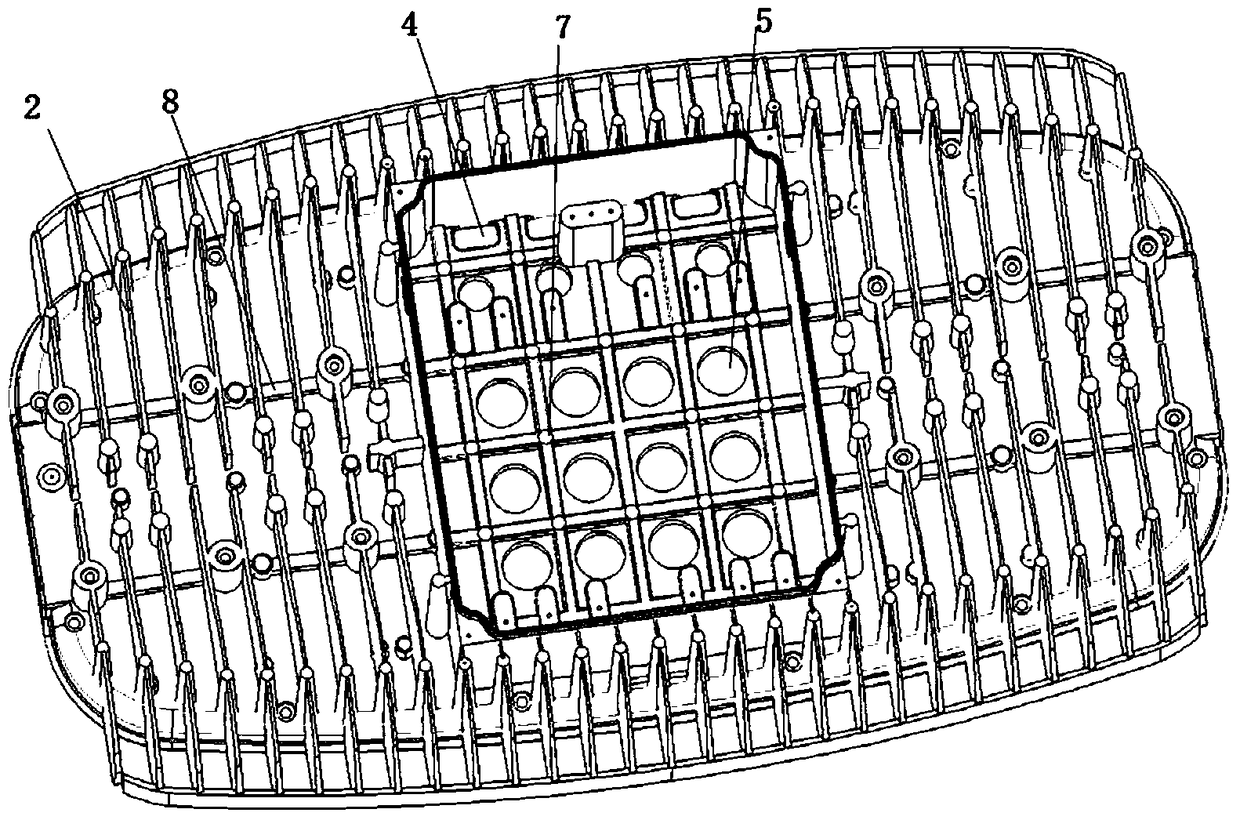

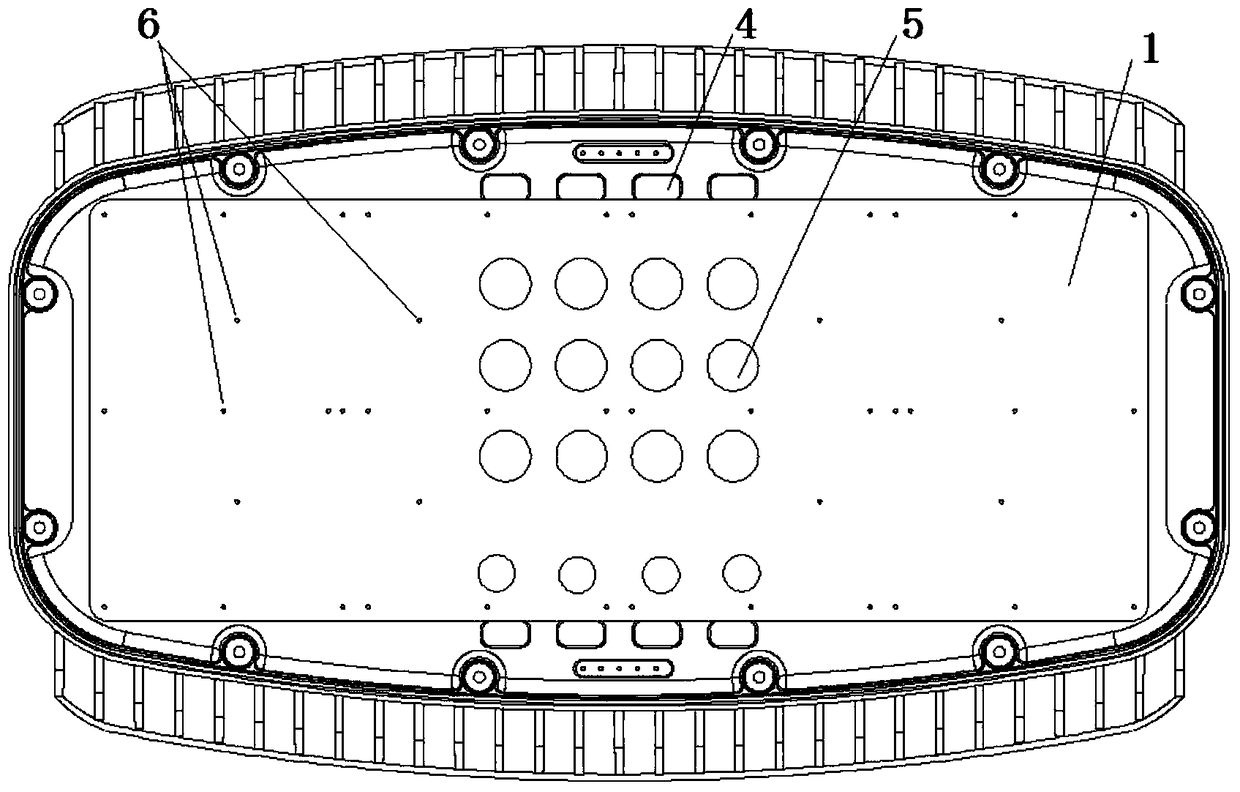

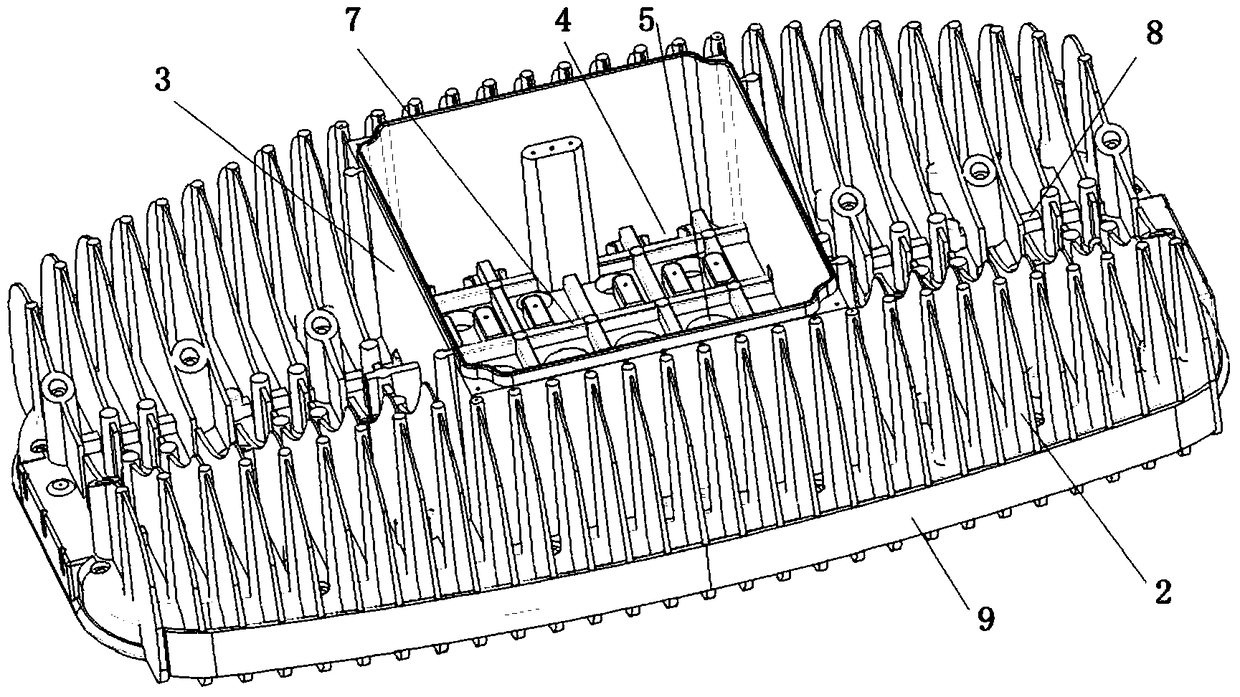

[0027] Such as Figure 1 to Figure 3 As shown, the high-power LED lamp has an integrated heat dissipation shell, and the back of the heat dissipation shell is provided with multiple rows of heat dissipation fins, and the heat dissipation fins are perpendicular to the length direction of the heat dissipation shell and parallel to the width direction of the heat dissipation shell; The front part is provided with a flat-plate mounting structure, and a plurality of reinforcing ribs are provided along the length direction on the back of the entire mounting structure (radiating fins are naturally used as reinforcing ribs in the width direction).

[0028] The power supply compartment and one or more LED chip mounting substrates are respectively fixed on the back and front of the mounting structure, and the projection positions of the power supply compartment and the LED chip mounting substrate on the mounting structure are staggered; correspondingly, on the back of the heat dissipatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com