A convenient and disassembled row light for plants

A plant and convenient technology, applied in the field of plant growth lamps, can solve the problems that users cannot flexibly adjust the light intensity, length, uneven light, etc., to achieve a wide range of applications, improve heat exchange efficiency, and high light utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be further described in detail through specific embodiments and in conjunction with the accompanying drawings.

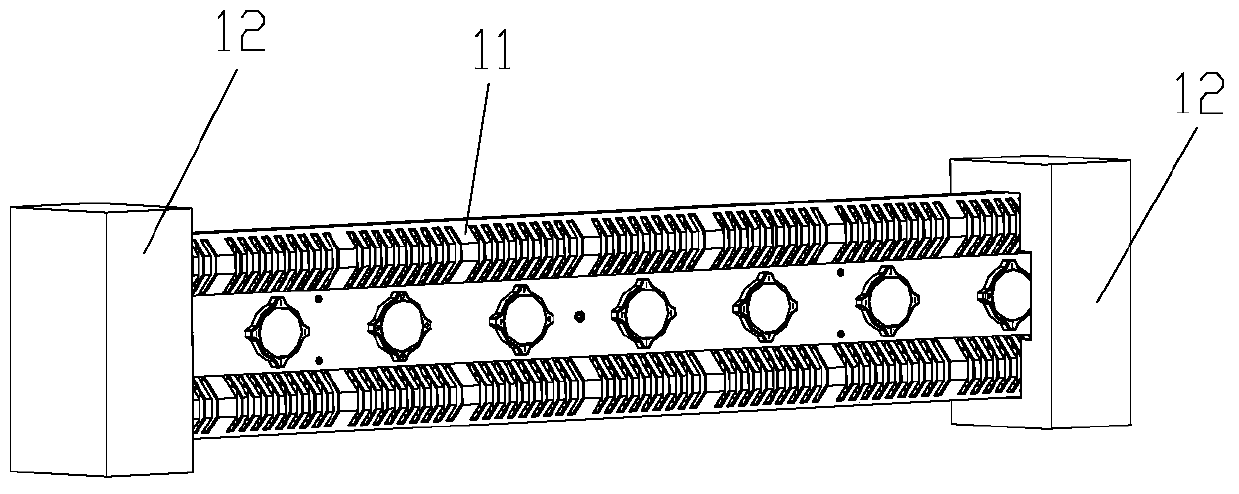

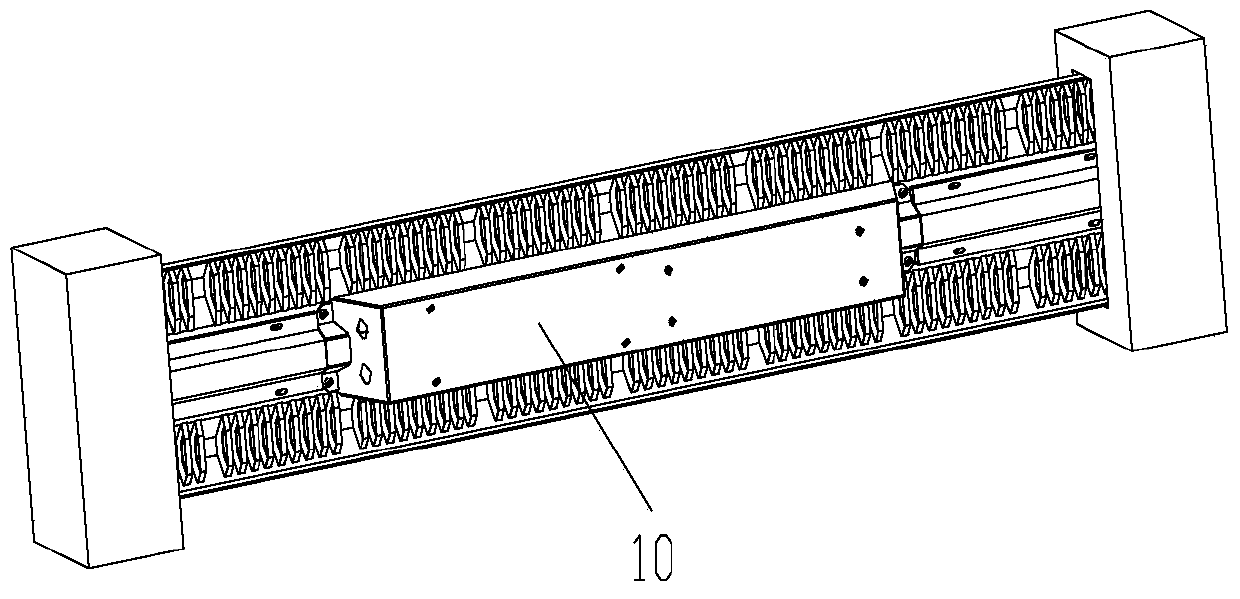

[0029] like Figure 1-5 As shown, a conveniently detachable interrow plant lamp includes a lamp housing, at least one light emitting module 20 and at least one circuit box 30 , and the structure of the above three major components will be further described below.

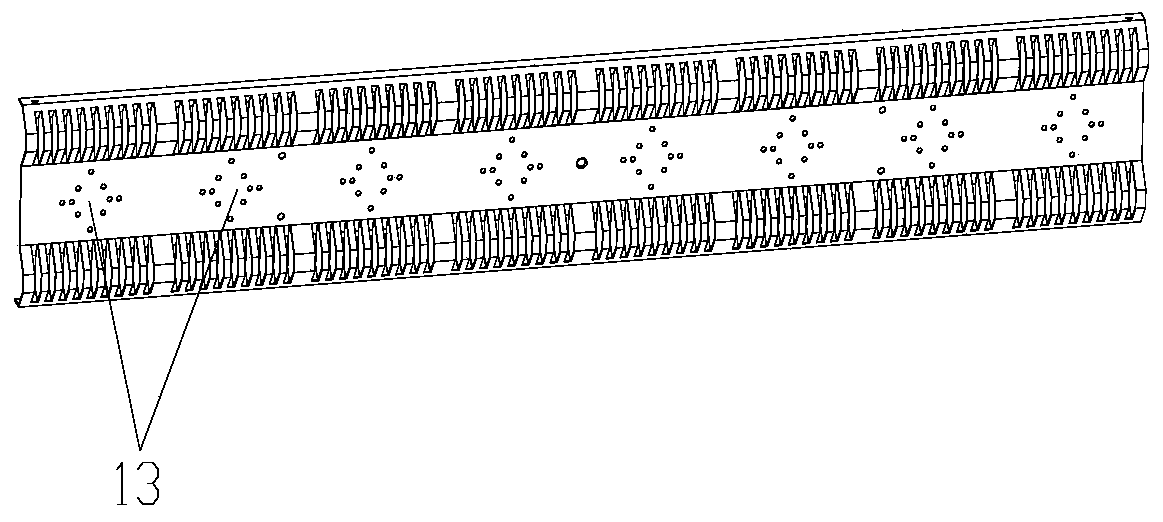

[0030] The lamp housing includes an upper housing 11 and a lower housing 10; the upper housing 11 and the lower housing 10 are covered and connected in a detachable manner to form an accommodating cavity; at least one side of the accommodating cavity is provided with a gap; The upper housing 11 is provided with at least one installation hole 13; the light-emitting module 20 includes a circuit board 21 and a lamp bead 22; at least one of the light-emitting modules is installed in the cavity; the circuit board 21 is provided with a lamp bead 22 fixing hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com