Capillary tube applied to monopropellant thruster

A capillary and thruster technology, which is applied in the field of capillary and 360° ultra-fine capillary, can solve the problems of large deviation between the length of the capillary and the frame size, difficulty in meeting precise control requirements, and large manufacturing errors, so as to improve work safety, Reduce the processing difficulty and manufacturing error, the effect of small structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

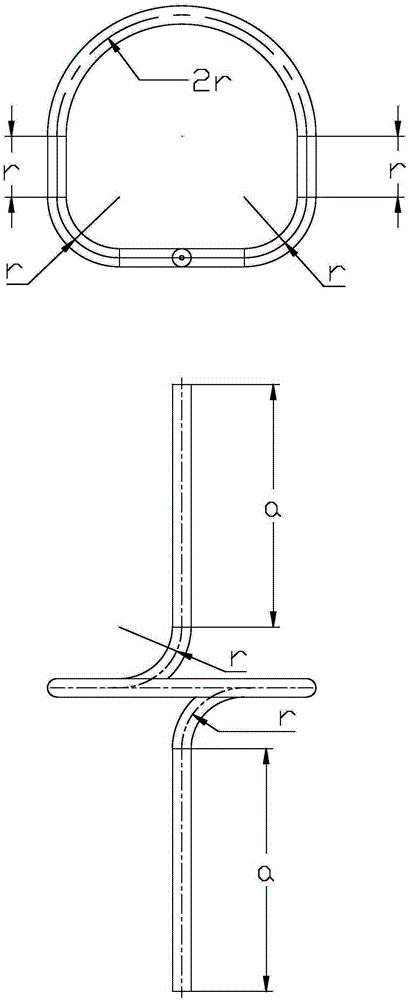

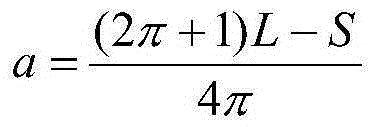

[0044] According to the requirements of flow resistance and the frame size of the single-unit thruster, determine S=45.12mm, L=20mm; according to the dimensions of S and L, obtain the capillary shape dimensions a=8mm and r=2mm.

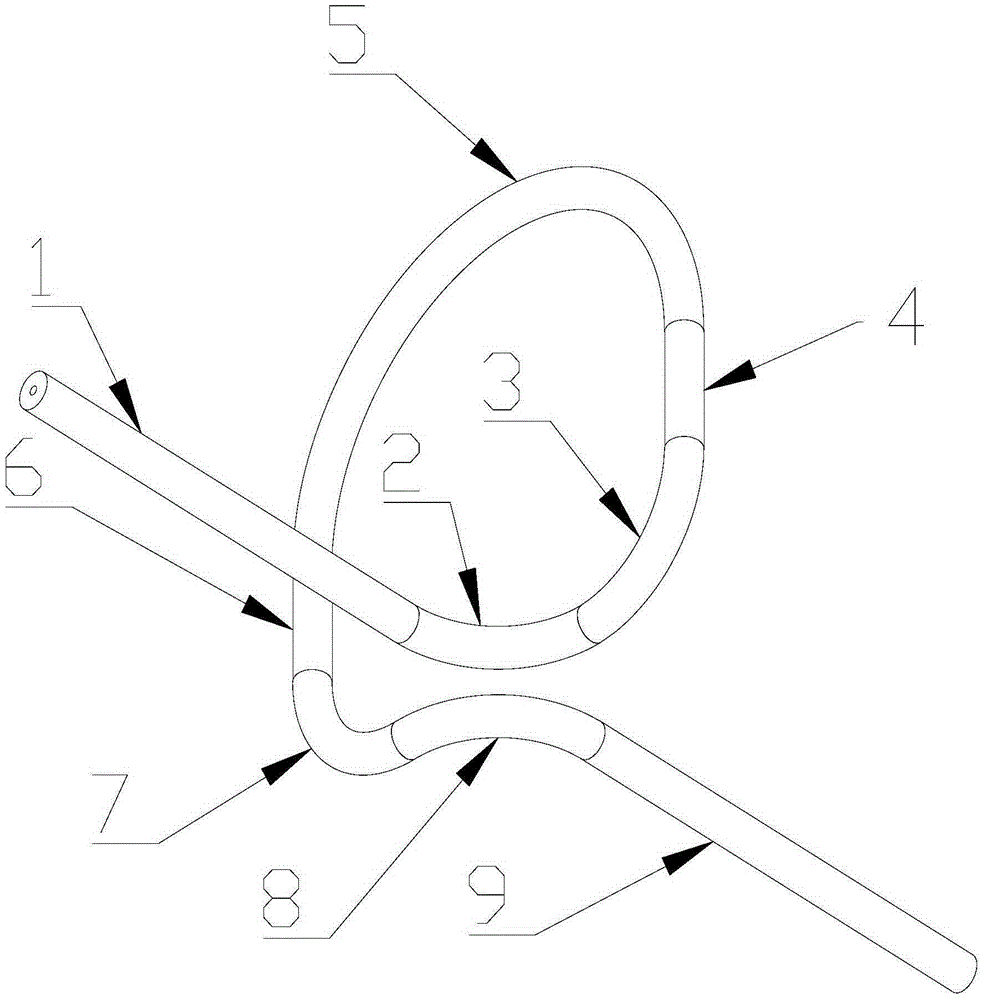

[0045] Such as figure 1 As shown, an ultra-fine capillary tube applied to a single-element thruster, the capillary tube is bent from a straight tube (total length 45.12mm) and includes a left straight tube section 1, a first arc section 2, and a second arc section 3. Left transition straight pipe section 4, third circular arc section 5, right transition straight pipe section 6, fourth circular arc section 7, fifth circular arc section 8 and right straight pipe section 9;

[0046] Such as figure 1 As shown, the left straight pipe section 1, the first circular arc section 2, the second circular arc section 3, the left transition straight pipe section 4, the third circular arc section 5, the right transition straight pipe section 6, the fourth circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com