A wheel hub motor for an electric vehicle

A technology for in-wheel motors and electric vehicles, applied in electric vehicles, motors, motor vehicles and other directions, can solve the problems of high energy consumption, rotor movement, poor stability of in-wheel motors, etc., and achieves good results, increased outer diameter, and rotor inner diameter. The effect of size expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, the present invention is further elaborated:

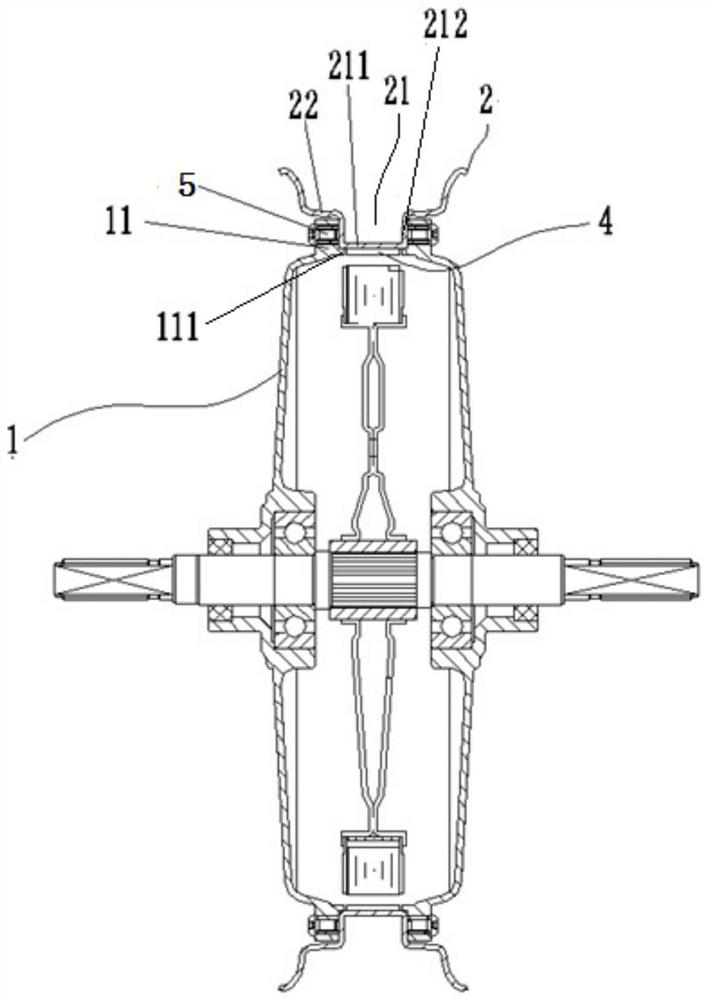

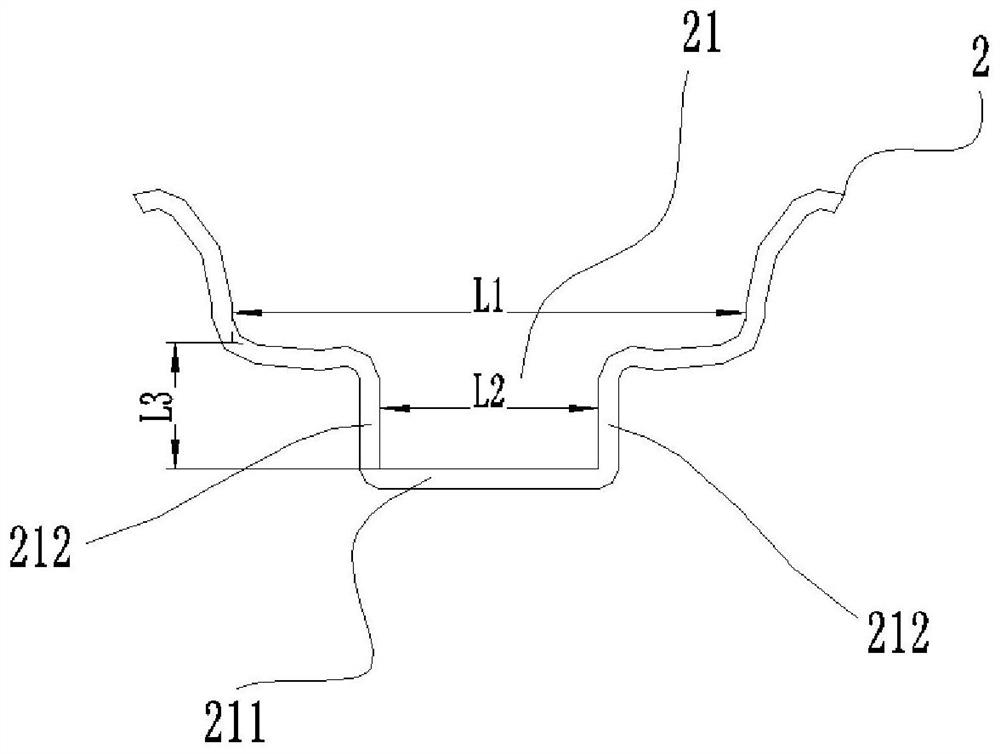

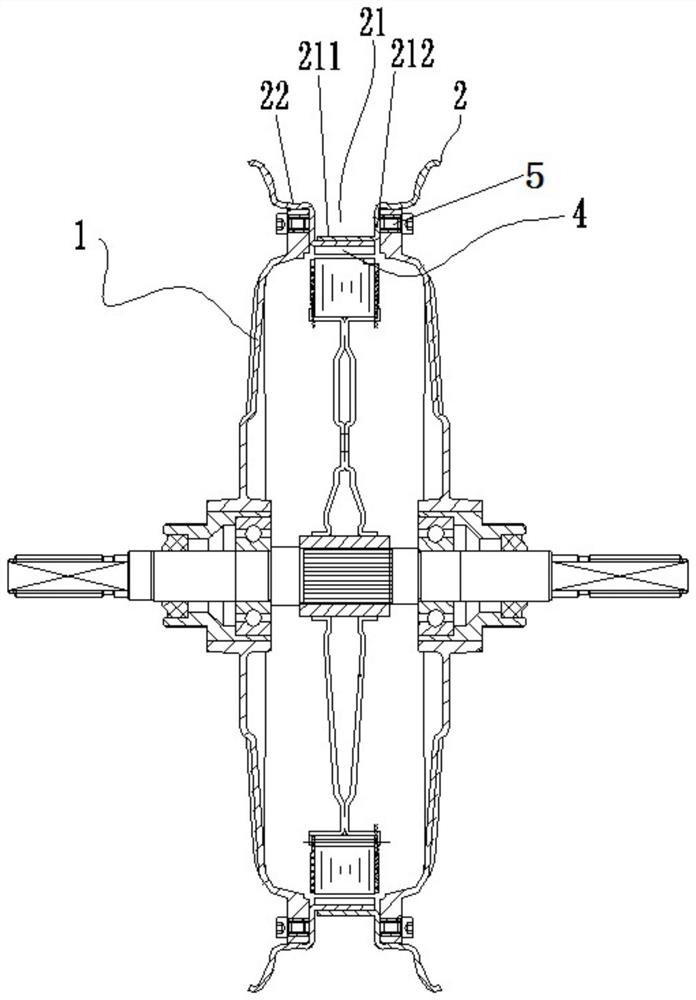

[0042] see Figures 1 to 11 As shown, a hub motor for an electric vehicle includes an end cover 1, a rim 2 and a permanent magnet 4. The end cover 1 is located on both axial sides of the rim 2 and the permanent magnet 4. The rim 2 includes a groove structure 21. The groove structure 21 includes a groove bottom wall 211 and a groove side wall 212, the depth of the groove structure 21 is not less than 7mm, and the angle between at least one side groove side wall 212 and the groove bottom wall 211 is between 90 and 96 degrees. The sum of the included angles between the groove side walls 212 and the radial direction is 0-22±6 degrees, and the ratio of the width of the groove bottom wall 211 to the nominal width of the rim 2 is 0.45-0.82. The included angle between at least one side wall of the groove and the bottom wall of the groove is set between 90 and 96 degrees, which is fav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com