Multi-interlayer detachable pin locking thread assembly for blind hole and locking method

A technology of threaded components and pins, applied in the directions of threaded fasteners, locking fasteners, screws, etc., can solve the problems of hidden safety hazards, poor safety reliability, and low flight safety factor of aerospace vehicles, and meet the requirements of High security and high reliability requirements, reasonable structural design, and excellent locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

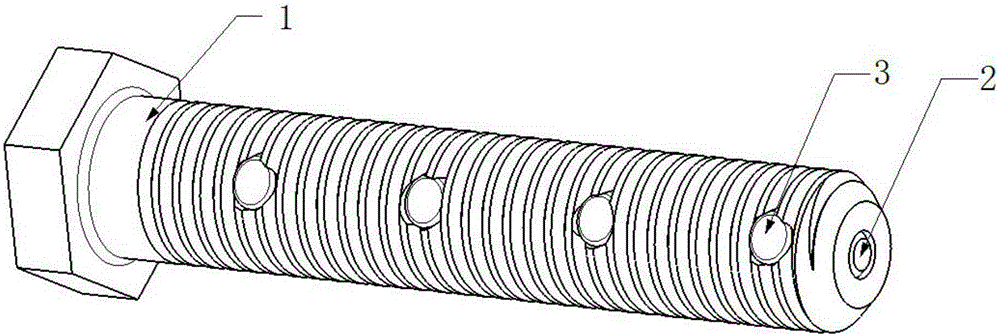

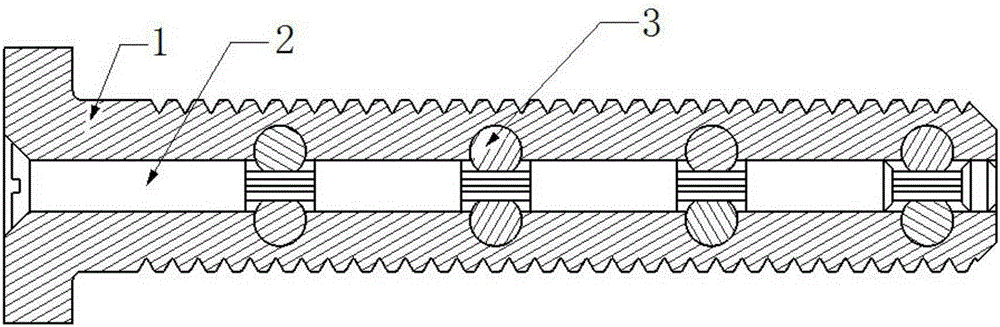

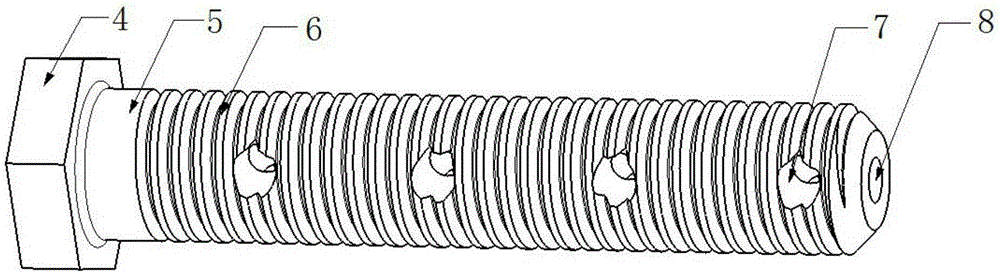

[0024] See Figure 1 to Figure 3 , the present invention includes an external screw 1 and an internal adjusting pin 2, and the center of the screw 1 is provided with an axially penetrating adjusting pin hole 8, and the adjusting pin 2 is located in the adjusting pin hole 8. In this embodiment, the screw 1 includes a head 4 and a stem 5 , and an external thread 6 is provided on the outer wall of the stem 5 .

[0025] See Figure 4 and Figure 5 It can be seen that the adjustment pin 2 includes an adjustment rod 11 with an adjustment end at one end and a tailpiece 12 at the other end, and a plurality of adjustment tooth columns 13 are formed at intervals on the rod body of the adjustment rod 11 . The outer end of the adjusting pin hole 8 is flared to form a groove for accommodating the adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com