A construction method of accumulative slippage of string trusses with columns at different elevations

A string truss and construction method technology, which is applied in the construction, building structure, processing of building materials, etc., to achieve the effect of increasing rigidity, accurate installation and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

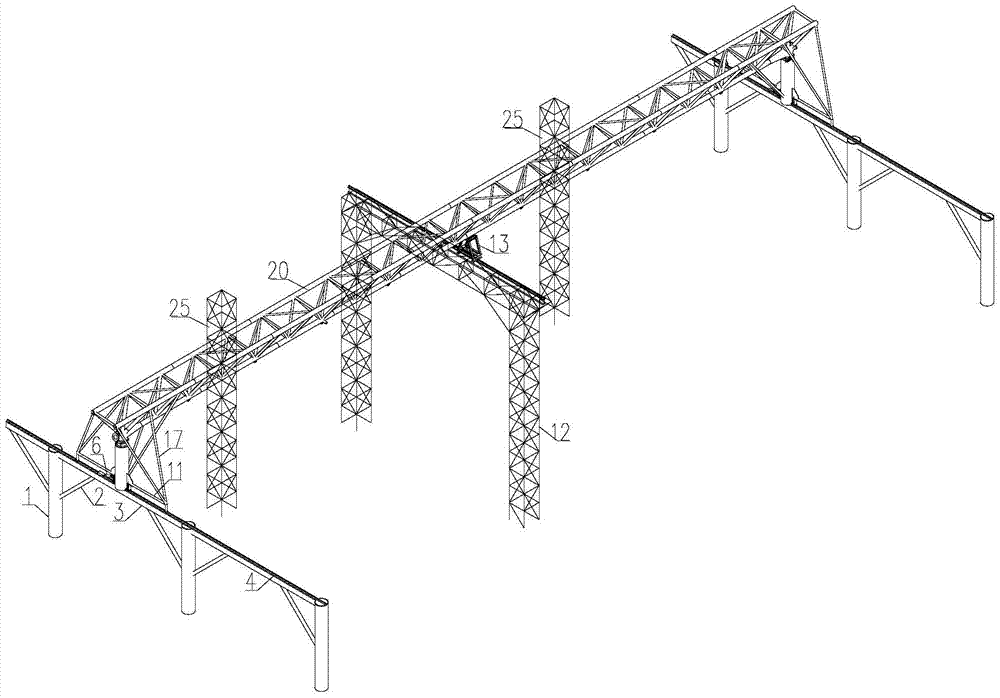

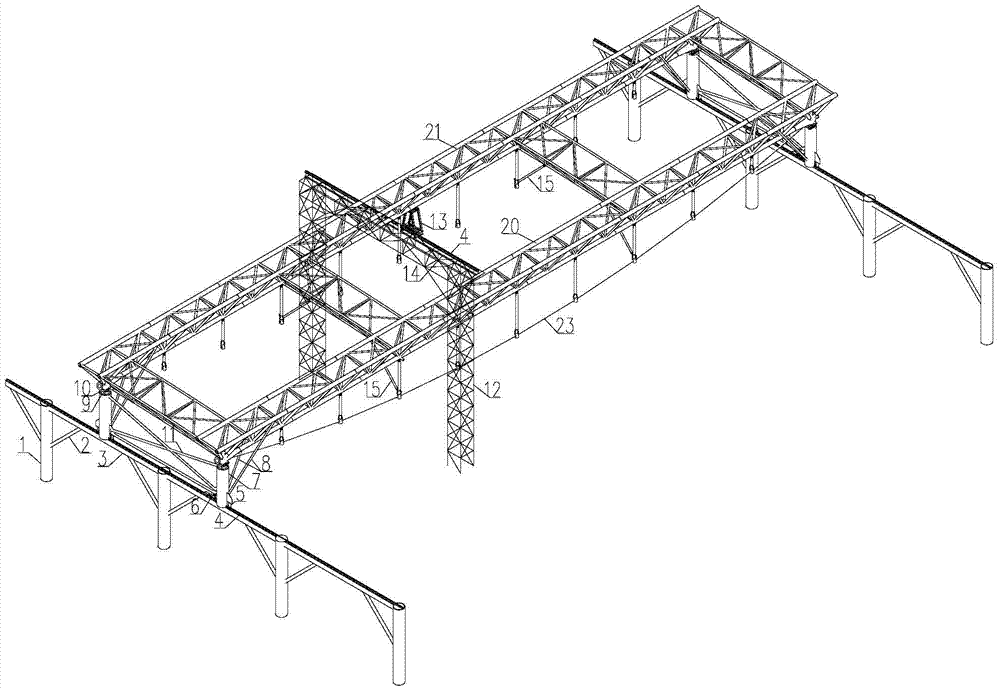

[0037] like Figure 1~7Shown is one of the embodiments of the present invention. A section structure of a convention and exhibition center adopts a stringed truss structure, which is mainly composed of a stringed truss, a vertical support truss, and a truss-supported steel column. The projected size of the structure is 142.5m×90m. The number of tension trusses is 8, and the distance between trusses is 12m~21.7m. The seat and the fixed hinge support are connected with the steel column.

[0038] Using the construction method of accumulative slippage with columns at different heights, the cumulative sliding of the roof structure with columns at a height of 23m is 142.5m, and the installation of the structure is completed. The specific steps are as follows:

[0039] (1). Long rails on both sides, short mid-span rails and independent support frame installation:

[0040] The top elevation of the load-bearing track beam 3 is determined according to the minimum elevation of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com