House interlayer cast-in-situ cavity floor

A cavity floor and interlayer technology, applied in the direction of floors, building components, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

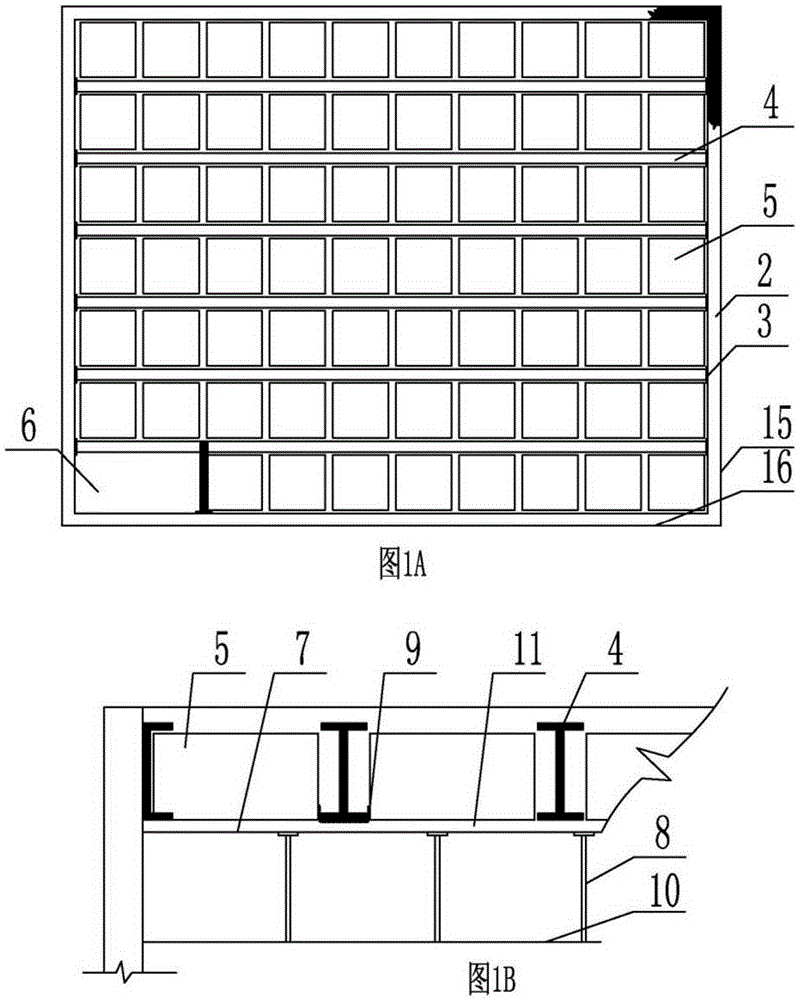

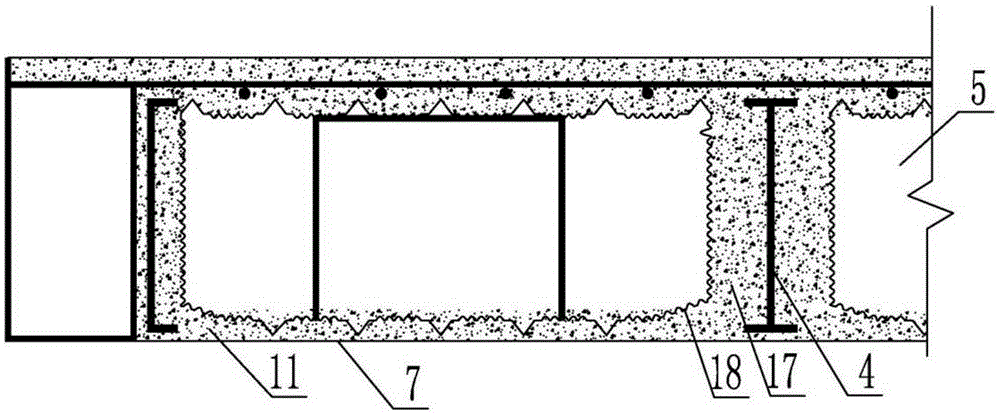

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] figure 1 It is a structural drawing of a cast-in-situ cavity floor slab of a house interlayer according to the present invention; figure 1 Decomposed into figure 1 A is the floor plan, figure 1 B is a sectional view. When the present invention is implemented, the position of adding another layer of mezzanine floor slabs is determined in the middle of the height of the interlayer space reserved for the main house building, and the shear wall 2 or the wall 2 at this position is used to generate the main beam, and in X The composite member 3 is installed on the wall of the axis or Y-axis; the support rod 8 of the sandwich formwork 7 is erected on the fixed floor 10; the stairway 6 is reserved, and the light steel beam 4 used for the sandwich floor is welded on the wall to install the composite member 3 to form Beam 4 of the mezzanine floor; in order to reduce th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com