Pseudomonas aeruginosa for producing rhamnolipid biosurfactant with palm oil and application thereof

A technology of Pseudomonas aeruginosa and rhamnolipid, applied in the biological field, can solve the problems of medium waste, product loss, inability to achieve defoaming, etc., and achieve the effects of high fermentation yield, high conversion rate, and high fermentation yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Optimization of ammonium nitrate concentration in Pseudomonas aeruginosa TIBR02 inorganic salt fermentation medium: Pseudomonas aeruginosa TIBR02 was inoculated in 10% palm oil as carbon source, and the concentration of sodium nitrate was 5g / L, 7.5g / L, 10g In the inorganic salt medium of / L, 12.5g / L and 15g / L, the other components of the medium are: 1.1g / LKCl; 1.1g / LNaCl; 0.00028g / LFeSO4.7H2O; 3.4g / LKH2PO4; 4.4g / LK2HPO4; 0.5g / LMgSO4.7H2O; 0.5g / L yeast powder. The appropriate trace elements added to the inorganic salt medium include: 0.29g / LZnSO4.7H2O; 0.24g / LCaCl2.4H2O; 0.25g / LCuSO4.5H2O; 0.17g / LMnSO4.H2O. Fermentation uses 250ml shake flasks with a liquid volume of 25ml, cultured at 30°C and 200r / min for 144 hours, and samples are taken every 24h to detect rhamnolipid production, dry cell weight and residual palm oil. Pseudomonas aeruginosa TIBR02 has the highest yield and highest conversion rate when the concentration of sodium nitrate is 7.5g / L, and the...

Embodiment 2

[0026] Example 2 Optimization of palm oil concentration in inorganic salt fermentation medium of Pseudomonas aeruginosa TIBR02:

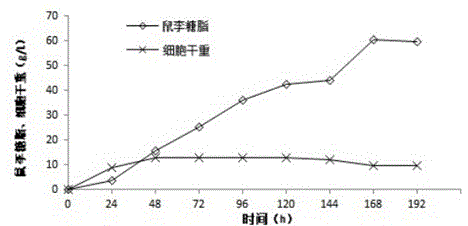

[0027] Pseudomonas aeruginosa TIBR02 was inoculated in inorganic salt medium with palm oil concentration of 75g / L, 100g / L, 125g / L and 150g / L respectively. The composition of inorganic salt medium was: 7.5g / LNaNO3; 1.1g / L LKCl; 1.1g / LNaCl; 0.00028g / LFeSO4.7H2O; 3.4g / LKH2PO4; 4.4g / LK2HPO4; 0.5g / LMgSO4.7H2O; 0.5g / L yeast powder. The appropriate trace elements added to the inorganic salt medium include: 0.29g / LZnSO4.7H2O; 0.24g / LCaCl2.4H2O; 0.25g / LCuSO4.5H2O; 0.17g / LMnSO4.H2O. A 250ml shake flask was used for fermentation with a liquid volume of 25ml, cultured at 30°C and 200r / min for 196 hours, and samples were taken every 24h to detect rhamnolipid production, dry cell weight and residual palm oil. The conversion rate of Pseudomonas aeruginosa TIBR02 was the highest when the concentration of palm oil was 75g / L, about 76.9%. Therefore, the concentra...

Embodiment 3

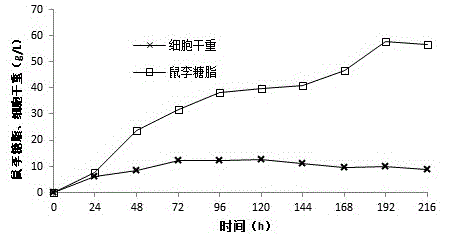

[0028] Example 3Under the optimal C / N conditions, palm oil was used as carbon source to carry out shake flask fermentation with Pseudomonas aeruginosa TIBR02: Pseudomonas aeruginosa TIBR02, 10% inoculum was inoculated in palm oil concentration of 75g / L, sodium nitrate 7.5g / L inorganic salt medium The other components of the medium are 1.1g / LKCl; 1.1g / LNaCl; 0.00028g / LFeSO4.7H2O; 3.4g / LKH2PO4; g / L yeast powder. The appropriate trace elements added to the inorganic salt medium include: 0.29g / LZnSO4.7H2O; 0.24g / LCaCl2.4H2O; 0.25g / LCuSO4.5H2O; 0.17g / LMnSO4.H2O. A 250ml shake flask was used for fermentation with a liquid volume of 25ml, cultured at 30°C and 200r / min for 216 hours, and samples were taken every 24h to detect rhamnolipid production, dry cell weight and residual palm oil. The highest yield was 57.73g / L in 192 hours, and the conversion rate was about 77%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com