Method for preparing formed coke

A technology of coal tar and cold press forming, which is applied in the field of coal chemical engineering, can solve the problems of coking cost increase and coking coal resource shortage, etc., and achieve the effects of reducing consumption, improving coke strength and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

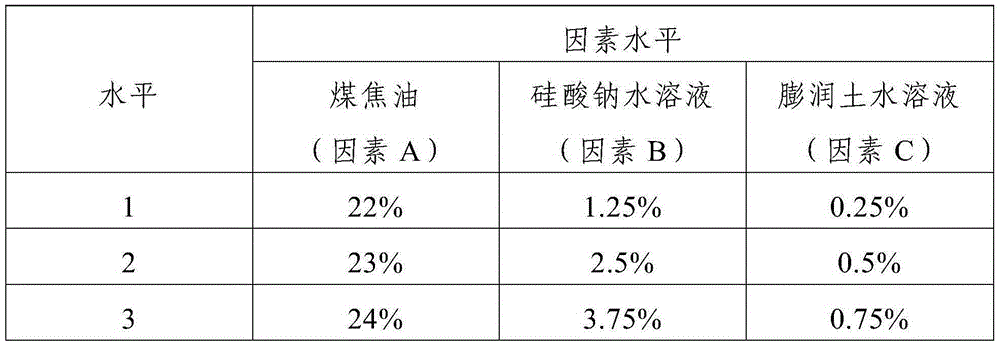

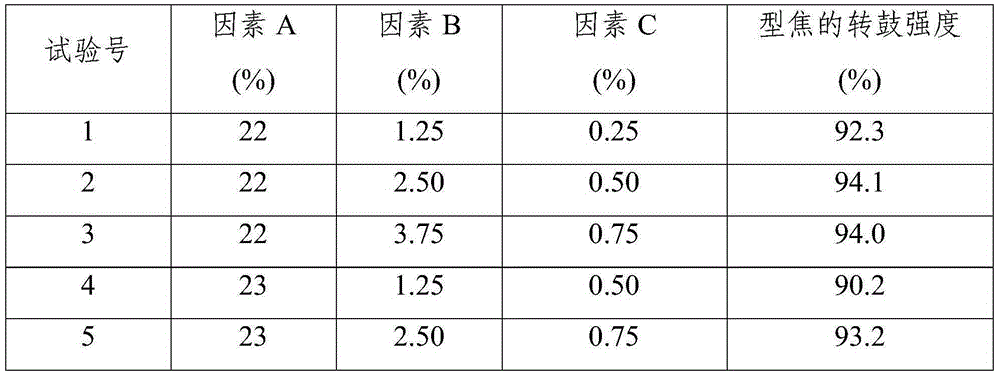

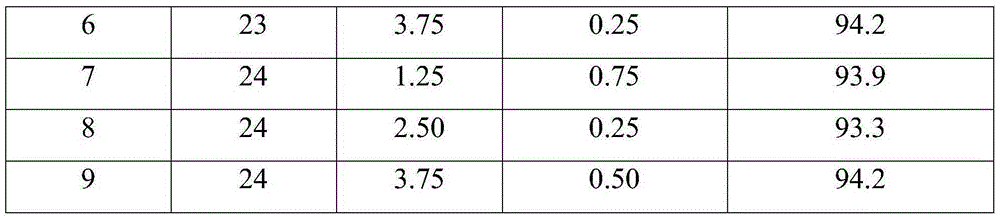

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of present embodiment form coke comprises the following steps:

[0022] Step 1, using deionized water as a solvent, respectively preparing a sodium silicate aqueous solution with a concentration of 2.0mol / L and a sodium bentonite aqueous solution with a concentration of 260g / L;

[0023] Step 2: Grinding Huangling coal into coal powder, adding coal tar, sodium silicate aqueous solution and sodium bentonite aqueous solution described in step 1 to the coal powder, mixing evenly, filling in the steel mold, and then using a hydraulic press Cold-press forming, the pressure of cold-press forming is 30MPa, obtains blank after demoulding, and the shape of described blank is cylindrical, and cross-sectional diameter is 50mm, and height is 45mm; The addition of described coal tar is 23% of the quality of pulverized coal. %, the addition of the sodium silicate aqueous solution is 3.75% of the pulverized coal quality, and the addition of the sodium bentonite a...

Embodiment 2

[0027] The preparation method of present embodiment form coke comprises the following steps:

[0028] Step 1, using deionized water as a solvent, respectively preparing a sodium silicate aqueous solution with a concentration of 2.5mol / L and a sodium bentonite aqueous solution with a concentration of 280g / L;

[0029] Step 2: Grind Shenfu coal into coal powder, add coal tar, sodium silicate aqueous solution and sodium bentonite aqueous solution described in step 1 to the coal powder, mix evenly, fill in the steel mold, and then use a hydraulic press to Cold-press forming, the pressure of cold-press forming is 30MPa, obtains blank after demoulding, and the shape of described blank is cylindrical, and cross-sectional diameter is 50mm, and height is 45mm; The addition of described coal tar is 22% of the quality of pulverized coal. %, the addition of the sodium silicate aqueous solution is 2.5% of the pulverized coal quality, and the addition of the sodium bentonite aqueous solution...

Embodiment 3

[0033] The preparation method of present embodiment form coke comprises the following steps:

[0034] Step 1, using deionized water as a solvent, respectively preparing a sodium silicate aqueous solution with a concentration of 3.0mol / L and a sodium bentonite aqueous solution with a concentration of 250g / L;

[0035] Step 2: Grind Datong coal into coal powder, add coal tar, sodium silicate aqueous solution and sodium bentonite aqueous solution described in step 1 to the coal powder, mix evenly, fill in the steel mold, and then use a hydraulic press to cool Compression forming, the pressure of cold forming is 30MPa, and the blank is obtained after demoulding, the shape of the blank is cylindrical, the cross-sectional diameter is 50mm, and the height is 45mm; the addition of the coal tar is 24% of the coal powder quality , the addition of the sodium silicate aqueous solution is 1.25% of the quality of coal powder, and the addition of the sodium-based bentonite aqueous solution is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com