Graphene nano-silver antibacterial coating and preparation method thereof

A nano-silver antibacterial and graphene technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of low decomposition efficiency and poor decomposition effect of antibacterial coatings, and achieve enhanced contact area. , Efficient and durable antibacterial effect, the effect of improving the antibacterial rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

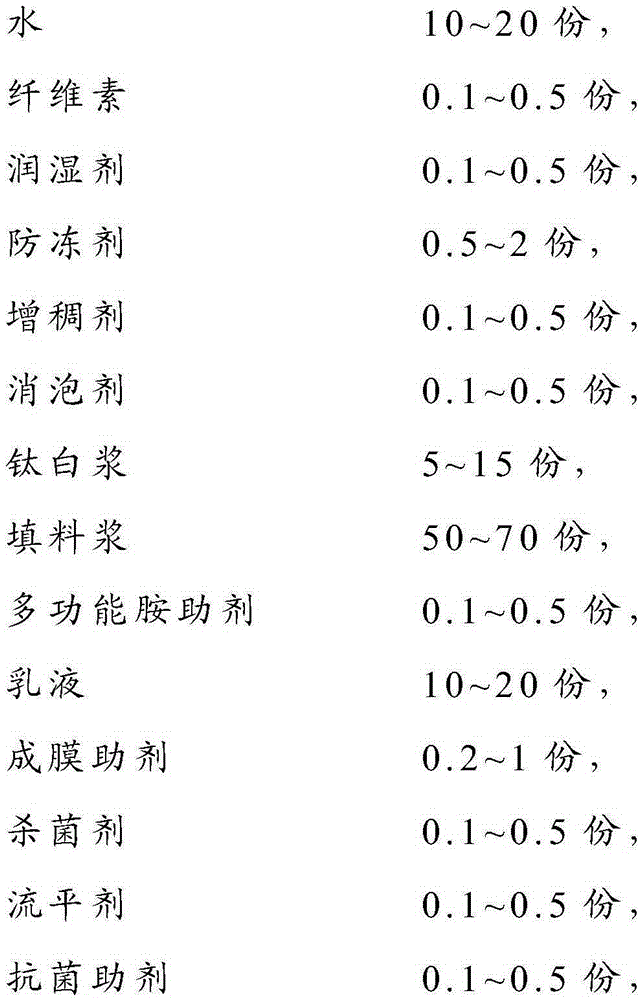

Method used

Image

Examples

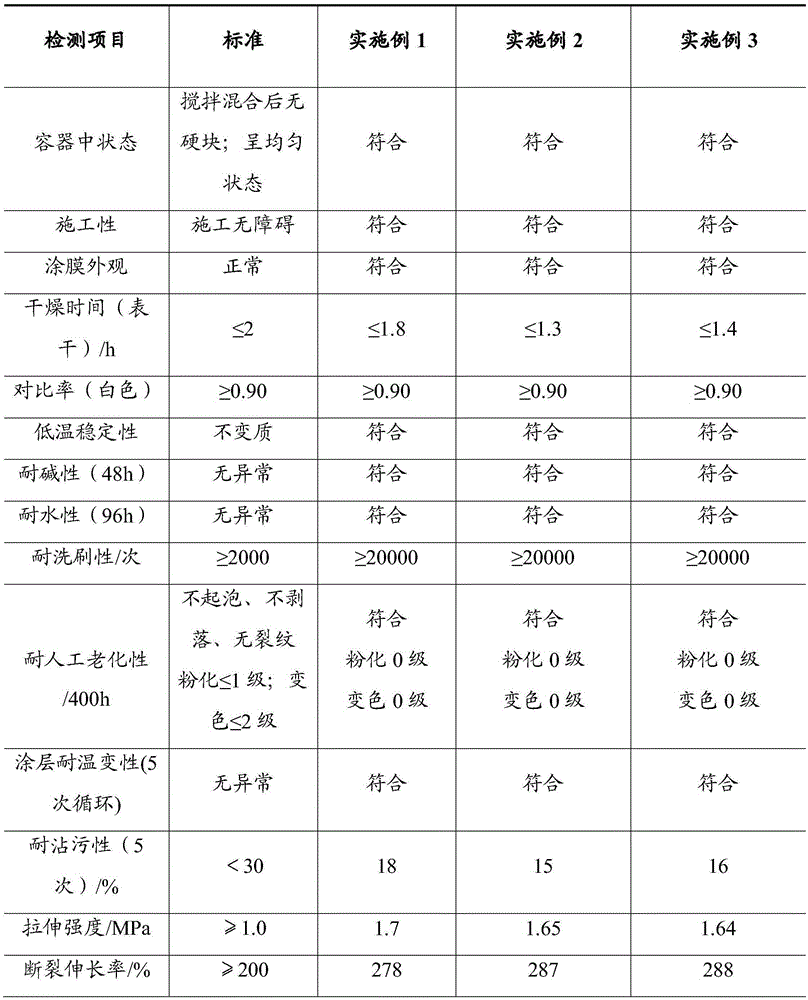

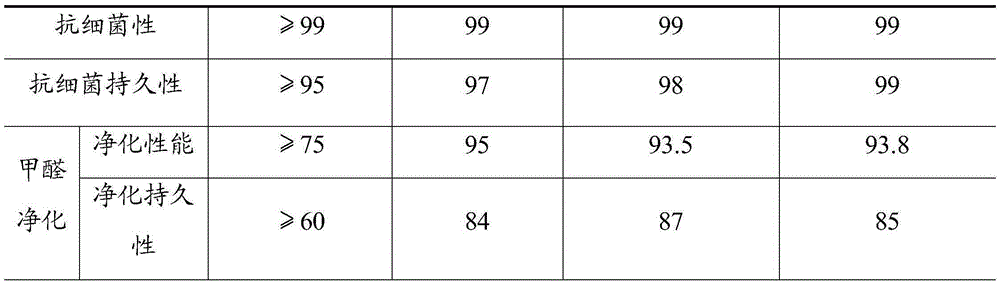

Embodiment 1

[0027] Embodiment 1. This embodiment provides a nano-silver antibacterial coating with a mass fraction of graphene nano-silver of 1‰ and a preparation method thereof. The following ingredients are included by weight fraction: 18 parts of water; 0.1 part of carboxymethylcellulose sodium salt; 0.1 part of alkyl aryl polyether; 0.5 part of propylene glycol; 0.2 part of associative alkali-swellable thickener (CHECOATVT-183); 0.2 parts of polyurethane thickener (CHECOATVT-903); 0.1 part of mineral hydrocarbon defoamer (CHECOATDF6684); 5 parts of titanium white slurry; 50 parts of heavy calcium carbonate slurry; multifunctional amine additive (AMP-95) 0.1 part; 10 parts of acrylic copolymer emulsion; 0.2 part of film-forming aid (TEXANOL ester alcohol); 0.1 part of bactericide (Clariant HF-I); 0.1 part of polydimethylsiloxane;

[0028] The preparation method is: first drop into the water of 13g in the mixing tank, then add 0.1g of carboxymethylcellulose sodium salt successively by s...

Embodiment 2

[0029] Example 2, this example provides a nano-silver antibacterial coating with a mass fraction of graphene nano-silver dispersion liquid of 3‰ and a preparation method thereof. Comprising the following components by weight fraction: 20 parts of water; 0.2 part of carboxymethylcellulose sodium salt; 0.2 part of diisooctyl hyaluronic acid acid salt; 1 part of ethylene glycol; associative alkali swelling thickener (CHECOATVT -183) 0.1 part; polyurethane thickener (CHECOATVT-903) 0.4 part; nonionic alkyl copolymer defoamer (CHECOATDF9000) 0.1 part; titanium white paste 10 parts; diatomaceous earth 60 parts; 0.2 parts of agent (AMP-95); 10 parts of pure acrylic polymer; 1 part of film-forming aid (TEXANOL ester alcohol); 0.2 parts of fungicide (Clariant HF-I); 0.2 parts of alkyl modified organosiloxane ; 0.3 part of antibacterial auxiliary agent.

[0030] The preparation method is: first put 14g of water into the stirring tank, then add 0.1g of carboxymethylcellulose sodium salt...

Embodiment 3

[0031] Embodiment 3, this embodiment provides a graphene nano-silver antibacterial coating with a mass fraction of graphene nano-silver dispersion liquid of 5‰ and a preparation method thereof. According to the weight fraction, each material composition is 15 parts of water; 0.2 part of carboxymethylcellulose sodium salt; 0.2 part of diisooctyl hyaluronate; 1 part of propylene glycol; associative alkali swelling thickener (CHECOATVT-183 ) 0.2 parts; 0.2 parts of polyurethane thickener (CHECOATVT-903); 0.4 parts of non-ionic alkyl copolymer defoamer (CHECOATDF9000) and mineral hydrocarbon defoamer (CHECOATDF6684); 10 parts of titanium white paste ; 55 parts of superfine calcite powder; 0.2 part of multifunctional amine additive (AMP-95); 10 parts of styrene-acrylic emulsion; 1 part of film-forming aid (TEXANOL ester alcohol); 0.2 part of bactericide; part; 0.5 part of antibacterial auxiliary agent.

[0032]The preparation method is: first put 12g of water into the mixing tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com