Clindamycin hydrochloride waste water processing technology

A technology for clindamycin hydrochloride and wastewater treatment, which is applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc. It can solve the problems of high COD content, high salt content, complex composition, etc., and achieve treatment efficiency. High, low COD concentration, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

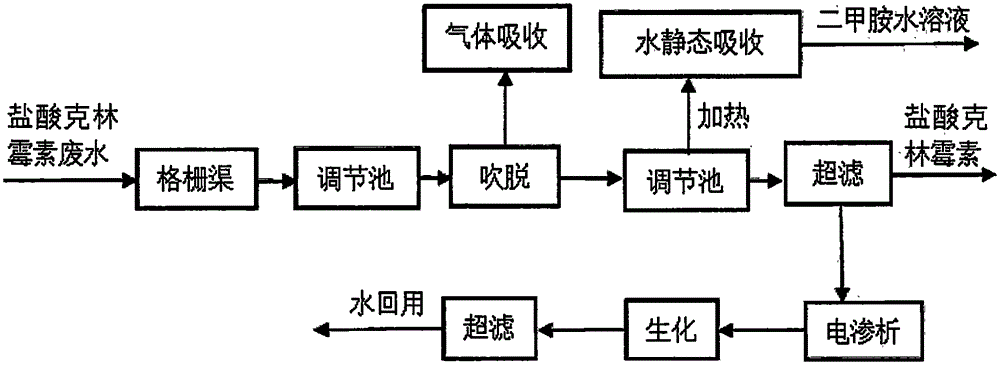

[0019] like figure 1 Shown, a kind of clindamycin hydrochloride waste water treatment process, it comprises the following steps: step (1) clindamycin hydrochloride waste water is intercepted to remove float and bulk impurity through the artificial grid in the grid ditch; ) the treated wastewater enters the regulating tank, and the wastewater volume and water quality are adjusted in the regulating tank; step (3) the wastewater is pumped into the stripping tower to remove the volatile liquid, and the gas stripped out is blown out with a gas absorption device Absorption, the waste water after stripping is discharged into the regulating pool; step (4) heats the waste water after stripping in the regulating pool, and reacts for a certain period of time so that the DMF in the waste water is fully decomposed, and the generated dimethylamine gas is statically absorbed by water , fully dissolved to generate an aqueous solution of dimethylamine, which is stored in a storage tank; in ste...

Embodiment 2

[0022] like figure 1 Shown, a kind of clindamycin hydrochloride waste water treatment process, it comprises the following steps: step (1) clindamycin hydrochloride waste water is intercepted to remove float and bulk impurity through the artificial grid in the grid ditch; ) the treated wastewater enters the regulating tank, and the wastewater volume and water quality are adjusted in the regulating tank; step (3) the wastewater is pumped into the stripping tower to remove the volatile liquid, and the gas stripped out is blown out with a gas absorption device Absorption, the waste water after stripping is discharged into the regulating pool; step (4) heats the waste water after stripping in the regulating pool, and reacts for a certain period of time so that the DMF in the waste water is fully decomposed, and the generated dimethylamine gas is statically absorbed by water , fully dissolved to generate an aqueous solution of dimethylamine, which is stored in a storage tank; in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com