Multi-cycle self-backflow small living sewage treatment system with denitrification function

A domestic sewage and treatment system technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve problems such as uneven water flow, difficult selection of water pumps, and low treatment efficiency , to achieve the effect of saving construction cost and maintenance cost, high energy utilization efficiency, and maintenance is not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

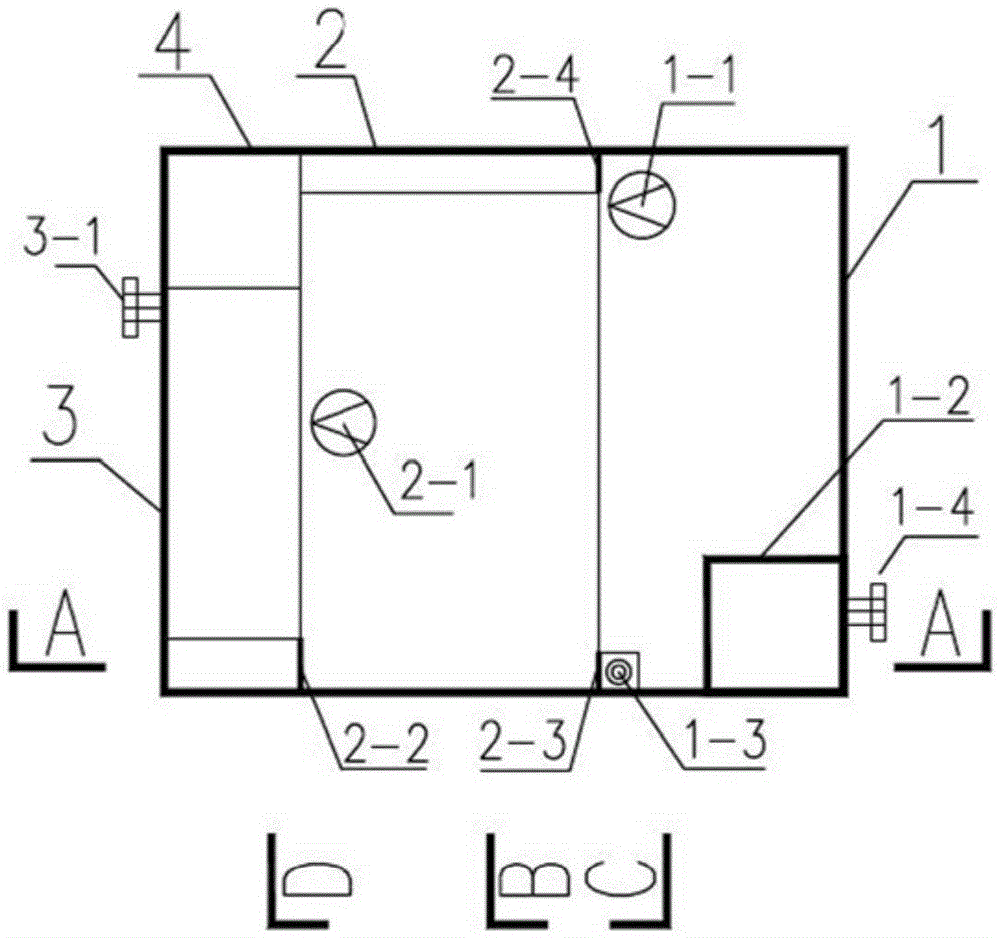

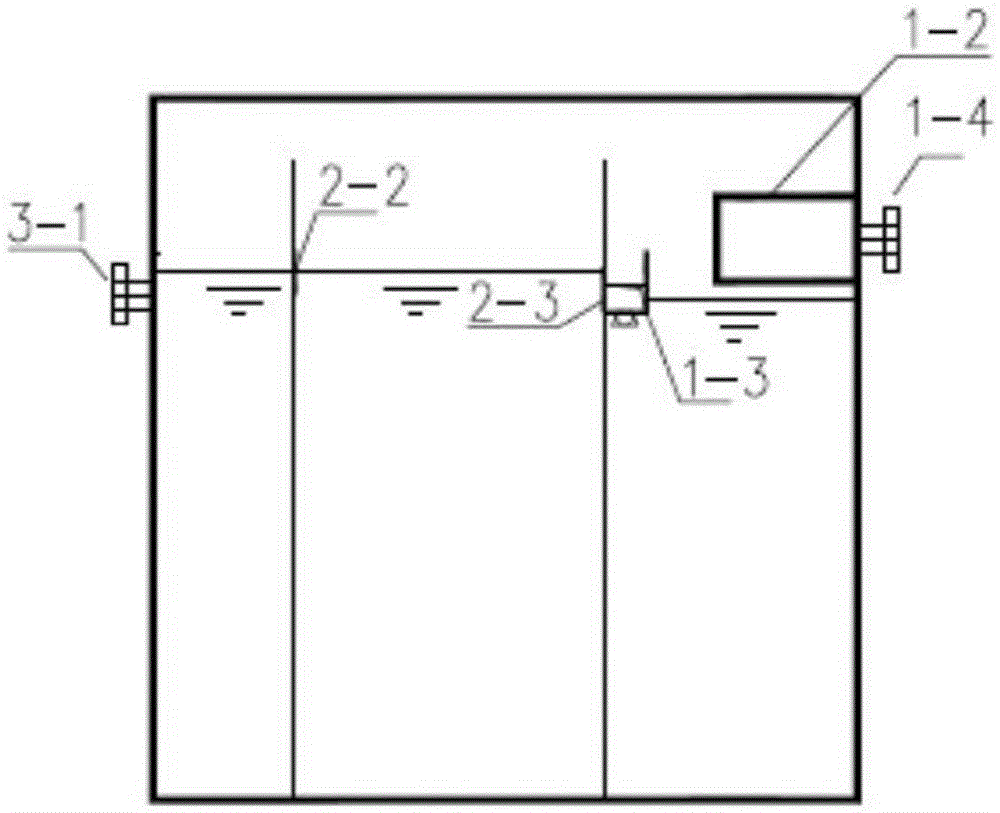

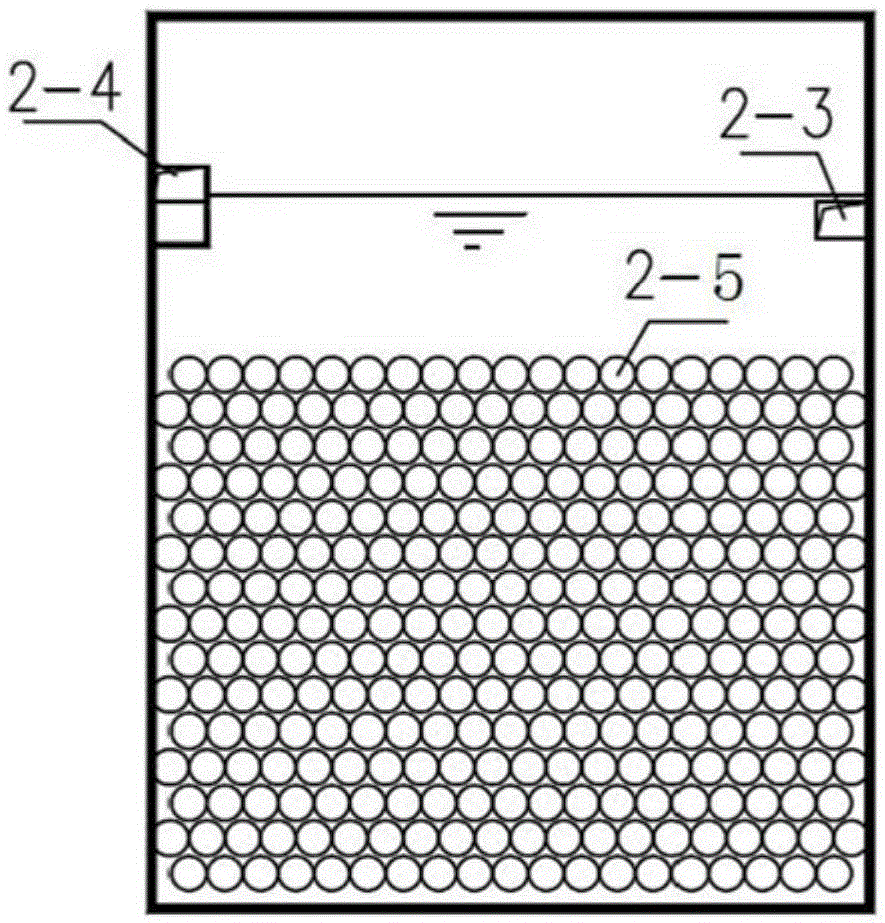

[0055] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 As shown, a multi-circulation self-reflux small-scale domestic sewage treatment system with denitrification function in the preferred first embodiment of the present invention is composed of three parts: water volume adjustment area 1, biochemical treatment area 2 and precipitation area 3. The described The biochemical treatment zone 2 is an aerobic biochemical reaction zone, while the water volume regulation zone 1 is an anoxic zone, and the sewage is circulated multiple times in the two zones to achieve a very high denitrification effect. in,

[0056] The water volume adjustment area 1 is provided with a lifting pump 1-1, a grid 1-2, a backflow device 1-3 and a water inlet 1-4, and the water inlet 1-4 is arranged in a part of the water volume adjustment area 1. On the upper part of the side pool wall, the grid 1-2 is arranged at the water inlet 1-4, and the return device 1-3 is arranged on t...

Embodiment 2

[0062] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a multi-circulation self-reflux small-scale domestic sewage treatment system with denitrification function according to the preferred second embodiment of the present invention is composed of four parts: water volume adjustment area 1, biochemical treatment area 2, precipitation area 3 and equipment area. in:

[0063] Wherein the weir top of the outlet weir 2-2 is at the same height as the top of the backflow weir 2-3, and the weir bottom of the outlet weir 2-2 is higher than the bottom of the backflow weir 2-3, by adjusting the top of the outlet weir 2-2 The height difference between the bottom of the weir mouth and the bottom of the backflow weir mouth 2-3 can adjust the return flow rate and the sewage treatment time, so that the water flow can be discharged after being processed through multiple cycles, so as to realize efficient sewage treatment.

[0064] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com