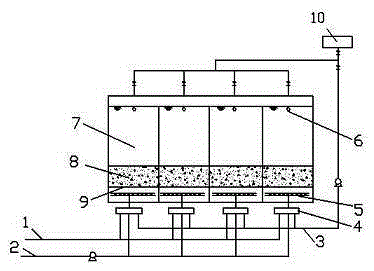

Ozone catalytic oxidation method and device

An ozone catalytic oxidation and ozone technology, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc. The effect of improving ozone utilization, improving ozone transfer coefficient and transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A sewage treatment plant was originally designed to feed domestic sewage, but now most of the actual feed water is papermaking wastewater. The biodegradability of influent water is low, and the main refractory pollutant is lignin. Most of the discharge enterprises served by the water plant have corporate sewage treatment stations, and the drainage is in accordance with the urban sewer discharge standards, but there is no special requirement for BOD. Therefore, most of the biochemical and easy-to-treat parts of the sewage have been treated in the sewage treatment stations of the enterprises themselves. However, although the COD of the sewage flowing into the sewage treatment plant does not exceed the sewer discharge standard, the difficulty of treatment is much higher than the sewer discharge standard.

[0075] The influent water is mixed wastewater from various enterprises in an economic development zone. The water quality is complex and the biochemical properties are e...

Embodiment 2

[0079] The treatment scale of a sewage treatment plant is 30000m 3 / day, the process flow is: Coarse grid—lift pump—fine grid—aeration grit chamber—hydrolytic acidification tank—A / O tank—secondary sedimentation tank—ultraviolet disinfection tank—water outlet. Industrial wastewater accounts for more than 60%, printing and dyeing wastewater accounts for about 85% of industrial wastewater, and the influent biodegradability is poor, B / C<0.25. The average value of influent COD is 298mg / L, the maximum value is 621mg / L, and the minimum value is 189mg / L; the average value of influent SS is 130mg / L, the maximum value reaches 350mg / L, and the minimum value is 50mg / L; The average value of water NH3-N is 12.5mg / L, the maximum value reaches 25mg / L, and the minimum value is 5.7mg / L. The influent chroma is higher, higher than 100 times. The COD of the effluent exceeds the standard, with an average value of 89mg / L, and the chroma of the effluent exceeds the standard, with an average value o...

Embodiment 3

[0083] The total scale of a sewage treatment plant project in an industrial park is 40,000m 3 / d, the design scale of the first phase is 20000m 3 / d, mainly treats industrial wastewater from petroleum, petrochemical and mechanical processing enterprises, and the designed daily treatment scale of the sewage treatment plant is 20,000m 3 / d. Industrial wastewater accounts for as high as 97.2% of the total influent, and industrial wastewater is mainly petrochemical wastewater. The process flow of the sewage treatment plant is: coarse screen - sewage lifting pump room - fine screen - advection grit chamber - hydrolytic acidification tank - AAO biochemical tank - secondary settling tank - secondary lifting pump room - coagulation sedimentation tank - fiber turntable Filter - UV disinfection pool.

[0084] The current influent water of the water plant mainly has the following problems: (1) The domestic sewage in the influent water accounts for only 2.8% of the total influent water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com