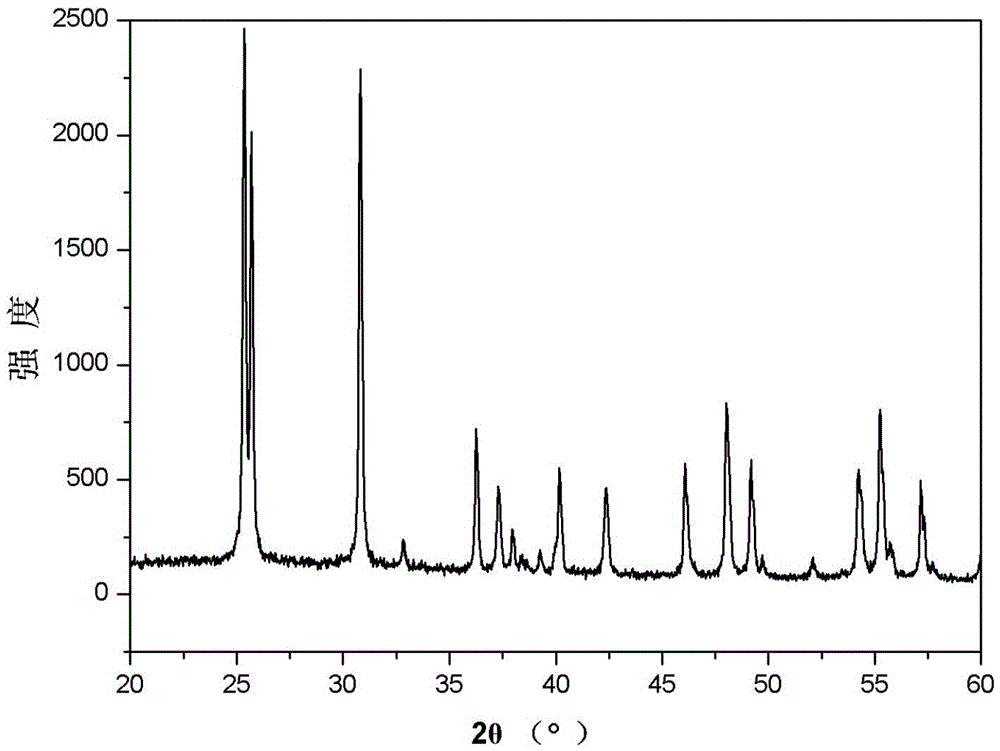

Preparation method of cauliflower-shaped brookite type titanium dioxide

A titanium dioxide, brookite-type technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of poor repeatability, short preparation period, low reaction temperature, etc., and achieve rich source of raw materials, short reaction period, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

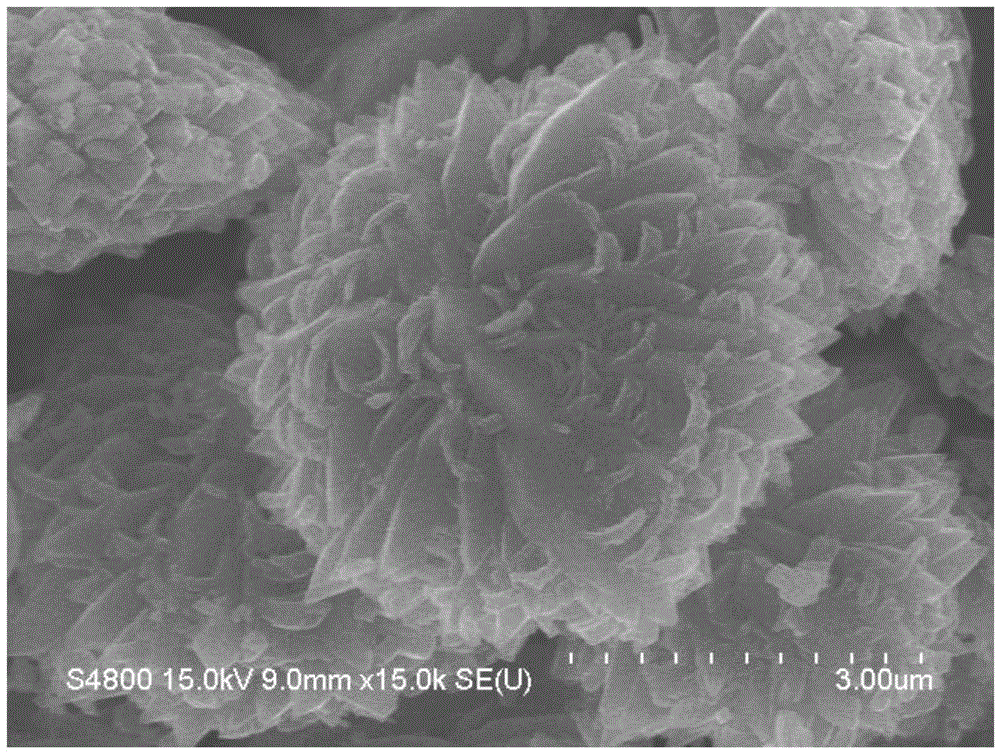

[0036] Add deionized water and titanium trichloride to the polytetrafluoroethylene lining of the reaction kettle to obtain 20 ml of a 0.8 mol / L titanium trichloride solution. Then, ammonia water was added to adjust the pH to 11. Finally, 10 ml of 2.5 mol / L sodium borohydride solution was added, and after stirring evenly, the mixture was placed in a high-temperature and high-pressure reactor, and placed in an oven at 250°C for 18 hours of reaction.

[0037]After the reactor was cooled to room temperature, the supernatant was absorbed and discarded. The lower precipitate was washed 6 times with deionized water and once with absolute ethanol. After washing, the precipitate was put into an oven at 60° C. for 12 hours to be vacuum-dried to obtain a cauliflower-shaped brookite-type titanium dioxide material.

[0038] The scanning electron microscope figure of embodiment 1 gained product is as figure 2 As shown, it can be seen from the figure that the resulting product is a titan...

Embodiment 2

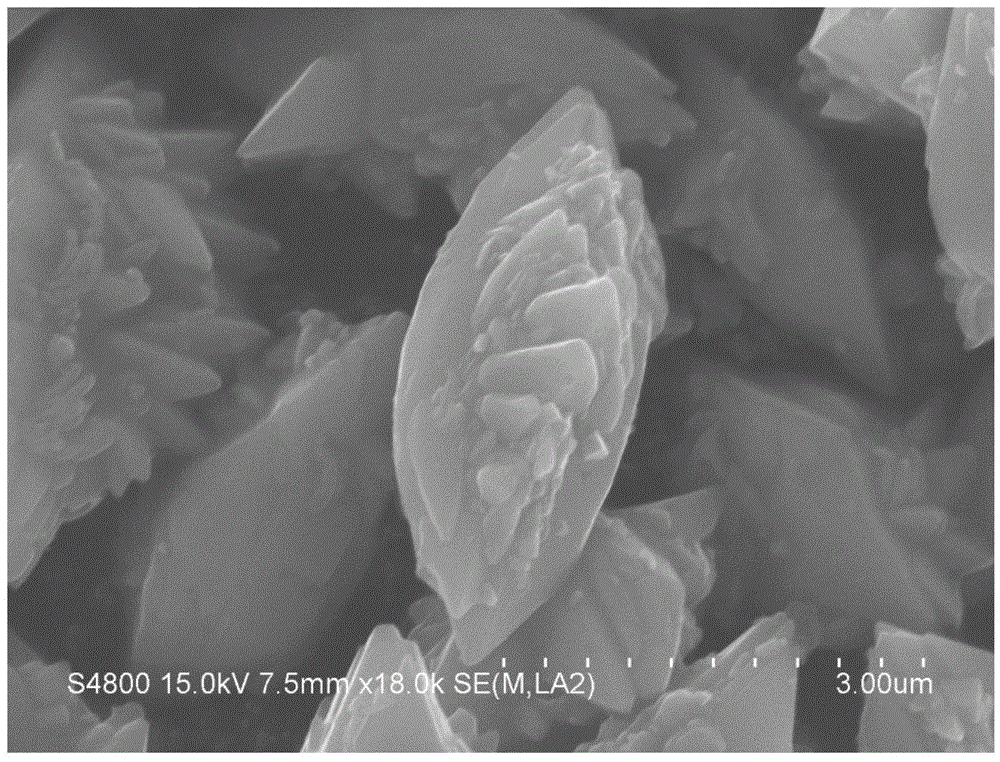

[0040] Add deionized water and titanium trichloride to the polytetrafluoroethylene lining of the reaction kettle to obtain 20 ml of a 0.8 mol / L titanium trichloride solution. Then, ammonia water was added to adjust the pH to 11. Finally, 10 ml of 2.5 mol / L sodium borohydride solution was added, stirred evenly, and the mixture was placed in a high-temperature and high-pressure reactor, and put into an oven at 250°C for 12 hours of reaction.

[0041] After the reactor was cooled to room temperature, the supernatant was absorbed and discarded. The lower precipitate was washed 6 times with deionized water and once with absolute ethanol. After washing, put the precipitate into a 60°C oven for vacuum drying for 12 hours to obtain a cauliflower-shaped brookite-type titanium dioxide material. image 3 is the scanning electron microscope image of the sample.

Embodiment 3

[0043] Add deionized water and titanium trichloride to the polytetrafluoroethylene lining of the reaction kettle to obtain 20 ml of a 0.8 mol / L titanium trichloride solution. Then, ammonia water was added to adjust the pH to 11. Finally, 10 ml of 2.5 mol / L sodium borohydride solution was added, stirred evenly, and the mixed solution was placed in a high-temperature and high-pressure reactor, and placed in an oven at 250°C for 24 hours of reaction.

[0044] After the reactor was cooled to room temperature, the supernatant was absorbed and discarded. The lower precipitate was washed 6 times with deionized water and once with absolute ethanol. After washing, put the precipitate into a 60°C oven for vacuum drying for 12 hours to obtain a cauliflower-shaped brookite-type titanium dioxide material. Figure 4 is the scanning electron microscope image of the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com