Direct pump control type electro-hydraulic heaving compensation device

A technology of heave compensation and pump control, applied in fluid pressure actuating devices, servo meter circuits, transportation and packaging, etc., can solve the problems of complicated pipeline connections, low system efficiency, and large volume, and achieve a simple system and reduce Device volume, no throttling loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

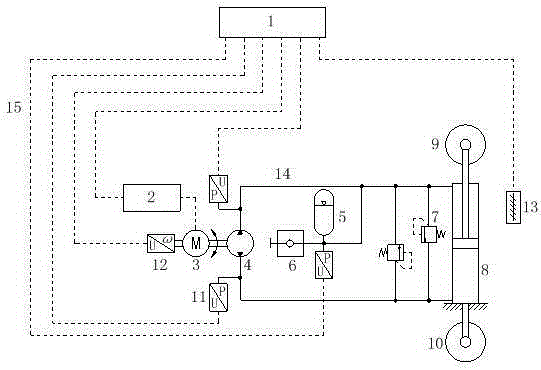

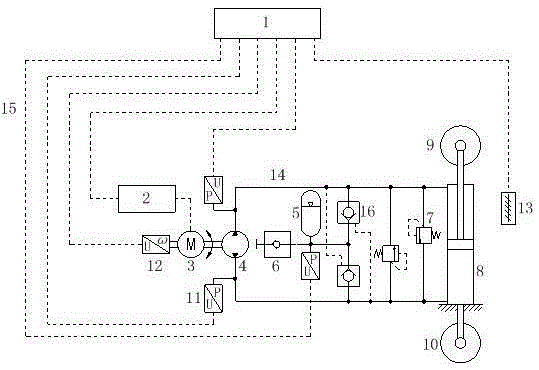

[0023] Such as figure 1 As shown, the present invention includes a control computer 1, a servo motor driver 2, a servo motor 3, a two-way hydraulic pump 4, an accumulator 5, a quick-plug joint 6, two overflow valves 7, a single rod hydraulic cylinder 8, and a movable pulley 9 , static pulley 10, three pressure sensors 11, speed sensor 12 and built-in displacement sensor 13.

[0024] The servo motor 3 driven by the servo motor driver 2 drives the two-way hydraulic pump 4 to rotate. The two output ends of the two-way hydraulic pump 4 are respectively connected to the rod chamber and the rodless chamber of the single-rod hydraulic cylinder 8 through the hydraulic pipeline 14. Two reversely installed overflow valves 7 are connected in parallel between the two output ends of the hydraulic pump 4; the accumulator 5 is divided into three circuits, the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com