A graphite processing center with a dust suction device

A technology of a graphite processing center and a dust collector, which is applied in stone processing equipment, smoke removal, and manufacturing tools, etc., can solve the problems of inability to treat and reuse graphite dust, affect the health of operators, waste graphite resources, etc. Dust efficiency, reduce energy consumption, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

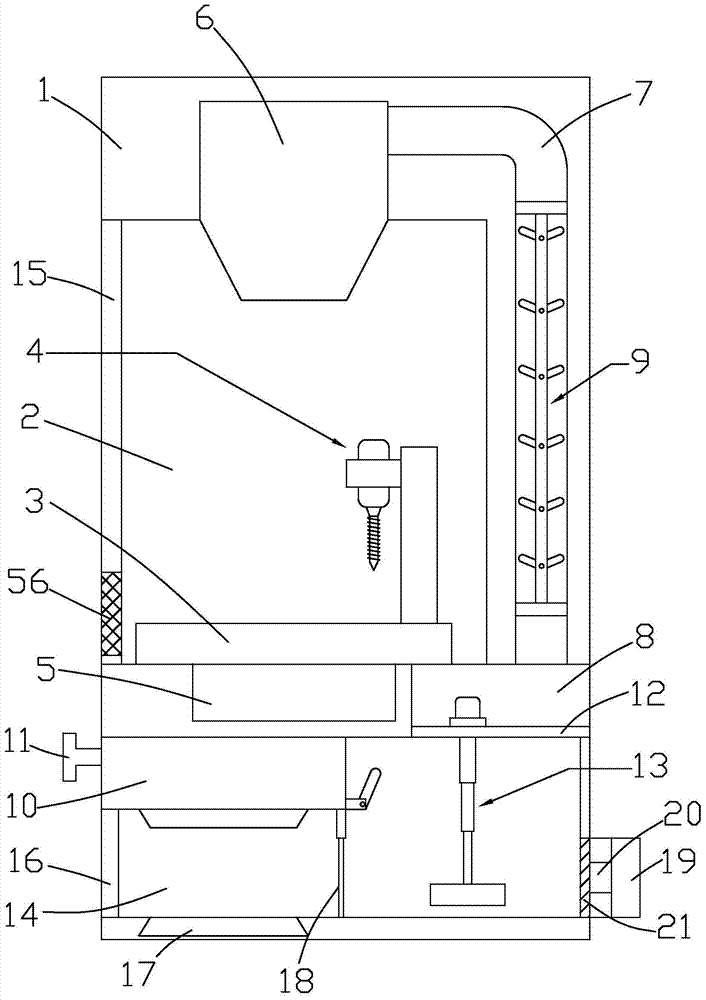

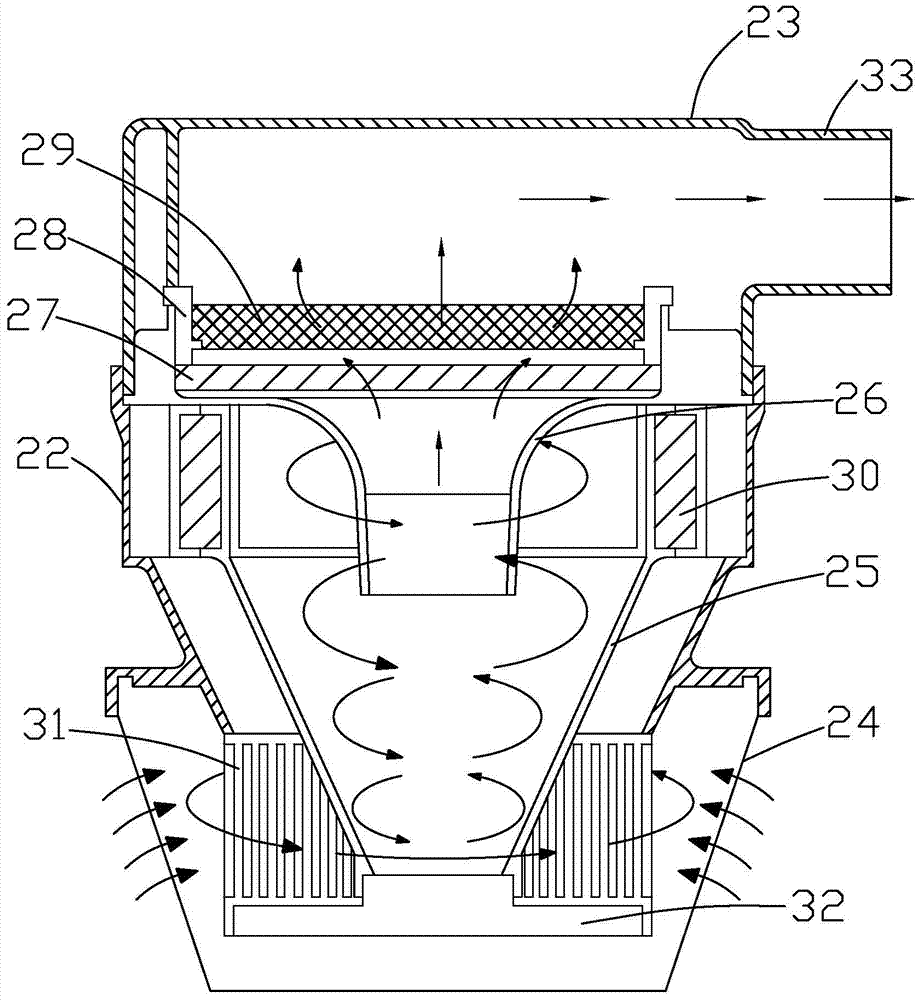

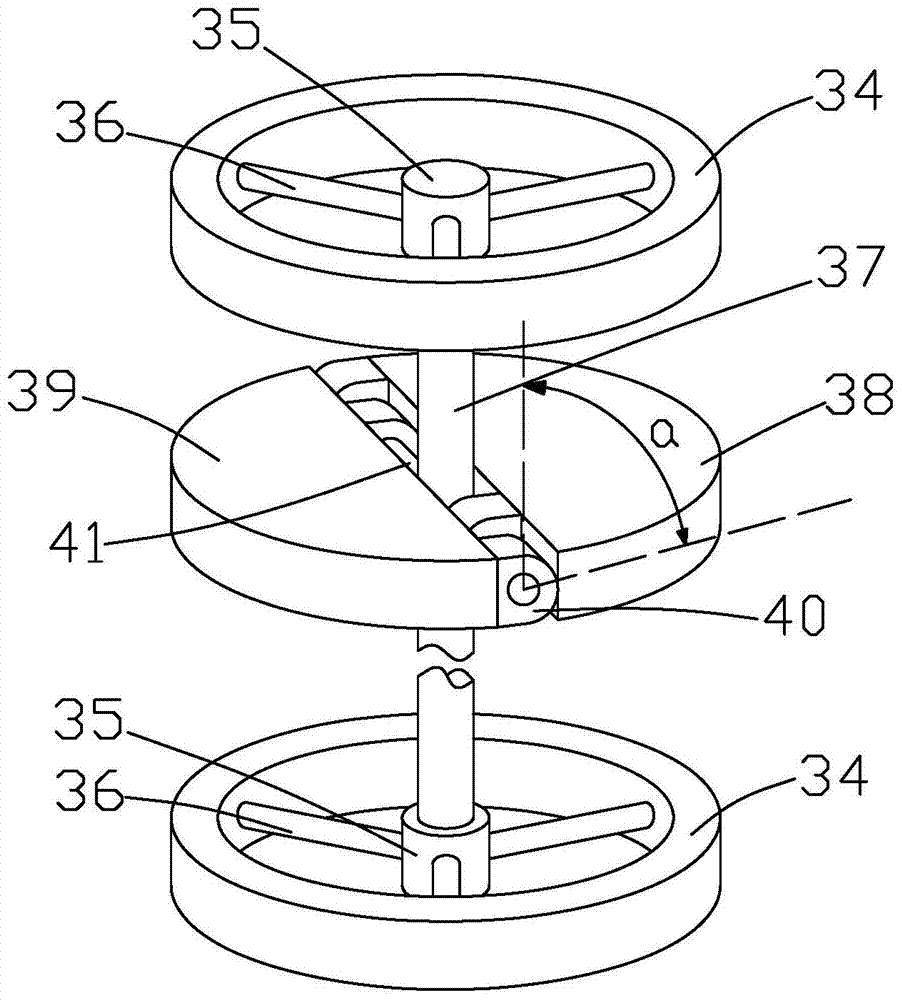

[0028] Such as Figure 1 to Figure 5 As shown, it is a graphite processing center with a dust suction device of the present invention, comprising a box body 1, a graphite processing room 2 is arranged inside the box body 1, a processing platform 3 and a processing tool 4 are arranged in the graphite processing room 2, The processing tool 4 is mobile connected on the processing platform 3, the bottom of the processing platform 3 is provided with a gear transmission box 5, the right side of the gear transmission box 5 is provided with a graphite powder processing box 8, and the graphite powder processing box 8 is provided with two mutually parallel Slide rail 12, slide rail 12 moves and is connected with extruding forming mechanism 13, extruding forming mechanism 13 comprises moving plate 48, telescoping mechanism and extruding block 55, and slide rail 12 is provided with chute 47, and moving plate 48 passes through The pulley 51 is connected to the slide rail 12, the pulley 51 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com