Vehicle wheel deburring device

一种去毛刺、车轮的技术,应用在磨削驱动装置、磨床、磨削机床的部件等方向,能够解决轮辋边角处毛刺处理效果达不到理想的要求、车轮法兰盘根部毛刺处理效果不好、刷毛线速度低等问题,达到结构简单、自动化程度高、工艺先进的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

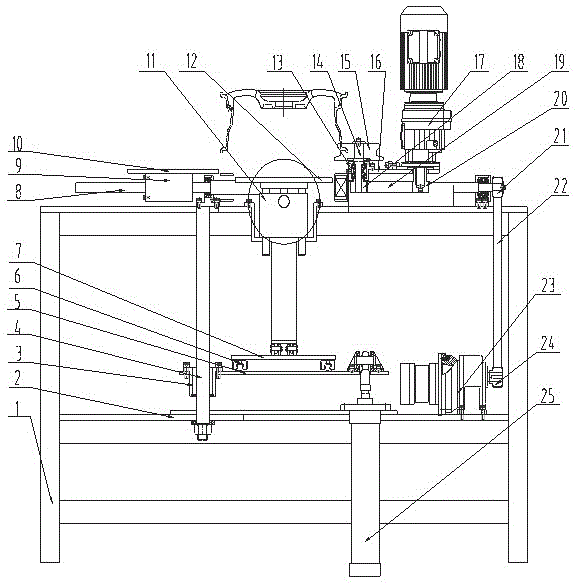

[0015] The details and working conditions of the specific device proposed according to the present invention will be described below in conjunction with the accompanying drawings.

[0016] The device consists of a frame 1, a bottom plate 2, a guide sleeve 3, a guide column 4, a lifting plate 5, a guide rail Ⅰ 6, a slide frame 7, a screw 8, a nut 9, a left sliding table 10, a lifting cylinder 11, a lifting plate 12, and a bearing Seat I13, shaft I14, V-shaped roller 15, right slide 16, drive motor 17, pulley I18, timing belt I19, pulley II20, pulley III21, timing belt II22, air motor 23, pulley IV24, lifting cylinder 25. Guide rail Ⅱ26, slider 27, servo electric cylinder Ⅰ28, servo electric cylinder Ⅱ29, connecting rod 30, pulley Ⅴ31, swing plate 32, synchronous belt Ⅲ33, brush 34, pulley Ⅵ35, bearing seat Ⅱ36, servo motor 37 , guide rail III38, cushion block 39, transmission roller table 40, transmission motor 41 and shaft II42 are formed, and four guide columns 4 are fixed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com