Automatic press-fitting mechanism and press-fitting method for retaining ring for idler shaft

A shaft retaining ring and idler shaft technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor intensity, low labor efficiency, and high labor costs, and improve the quality and versatility of pressing. Strong, accurate feed rate and feed rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

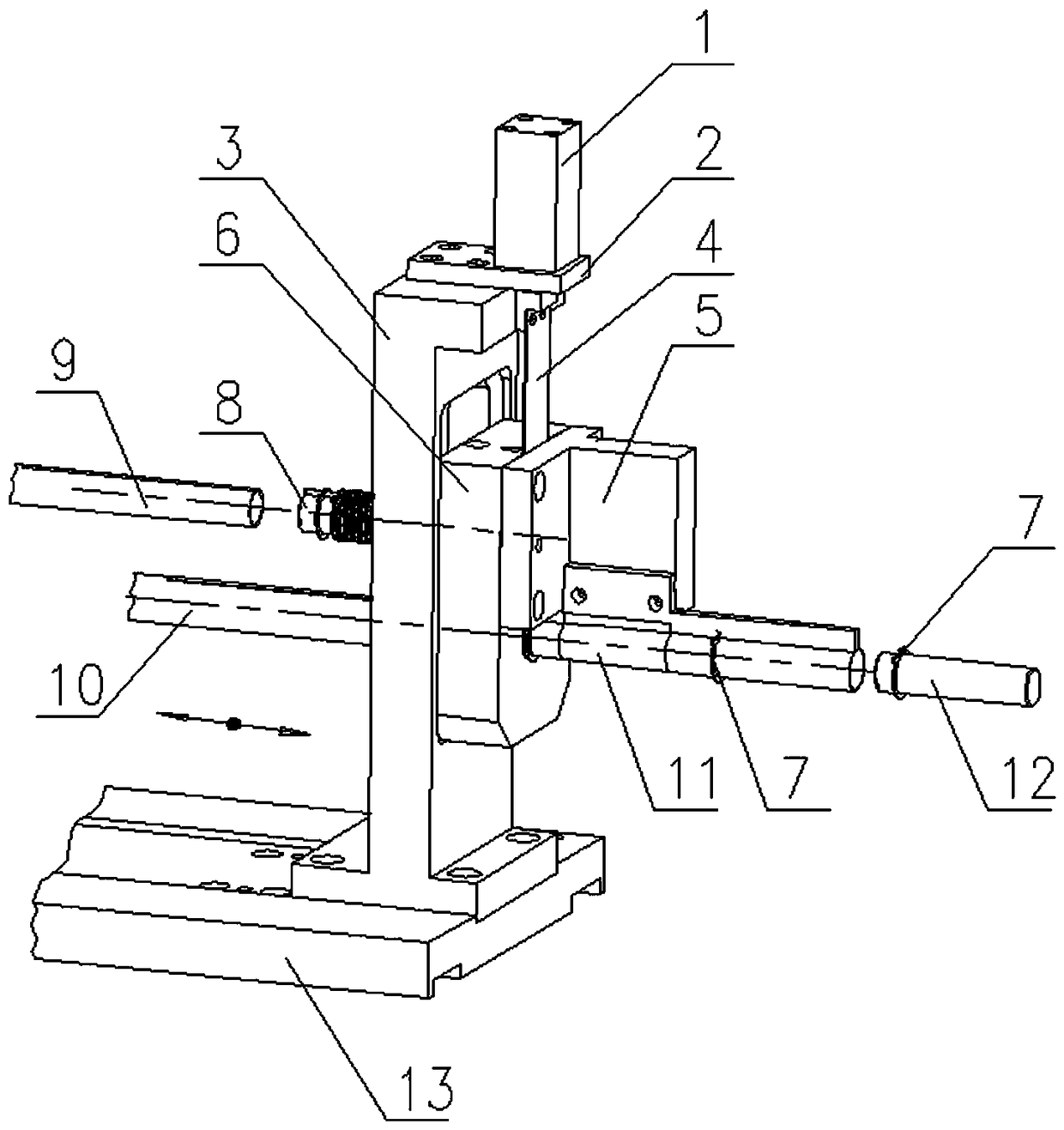

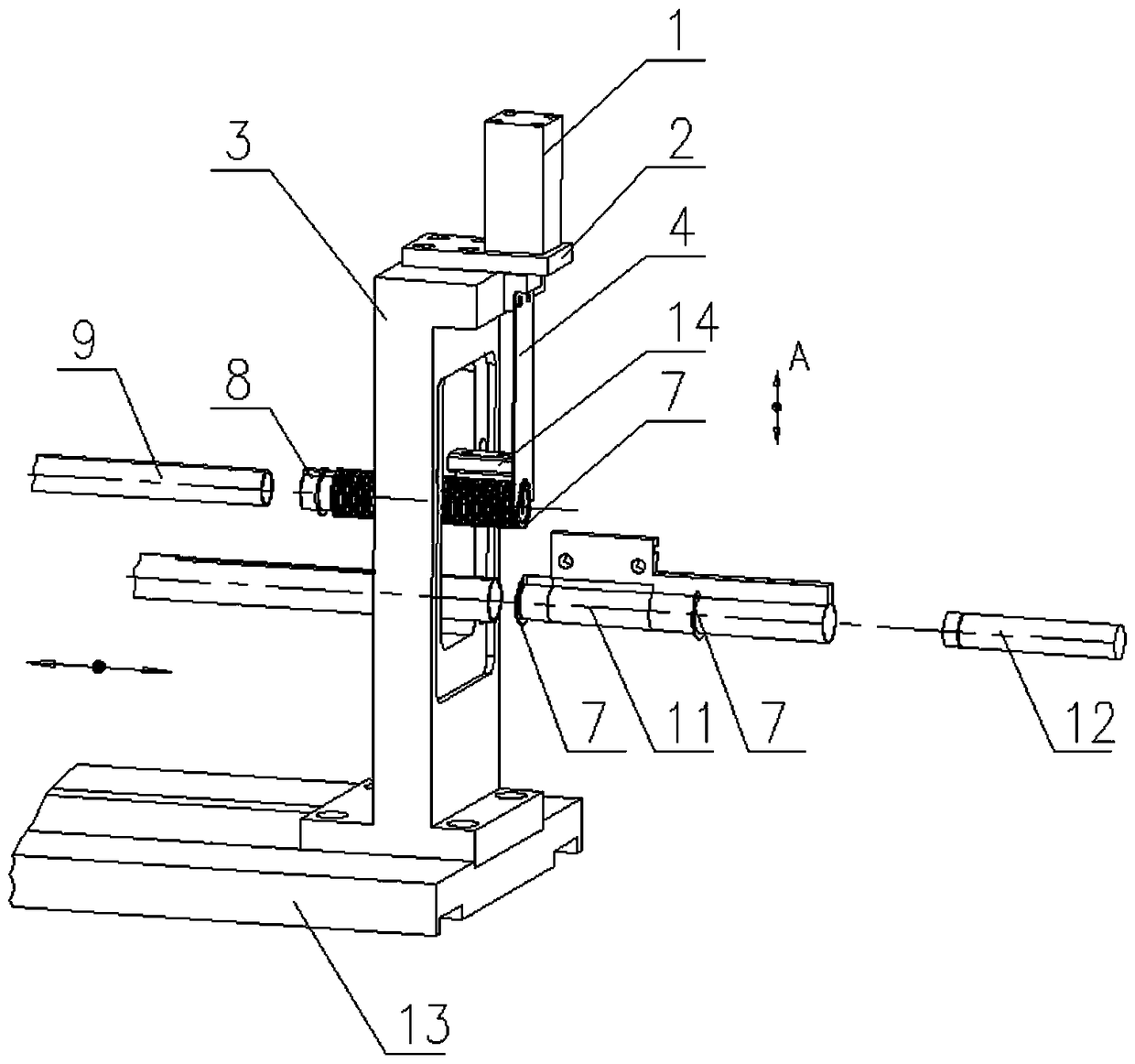

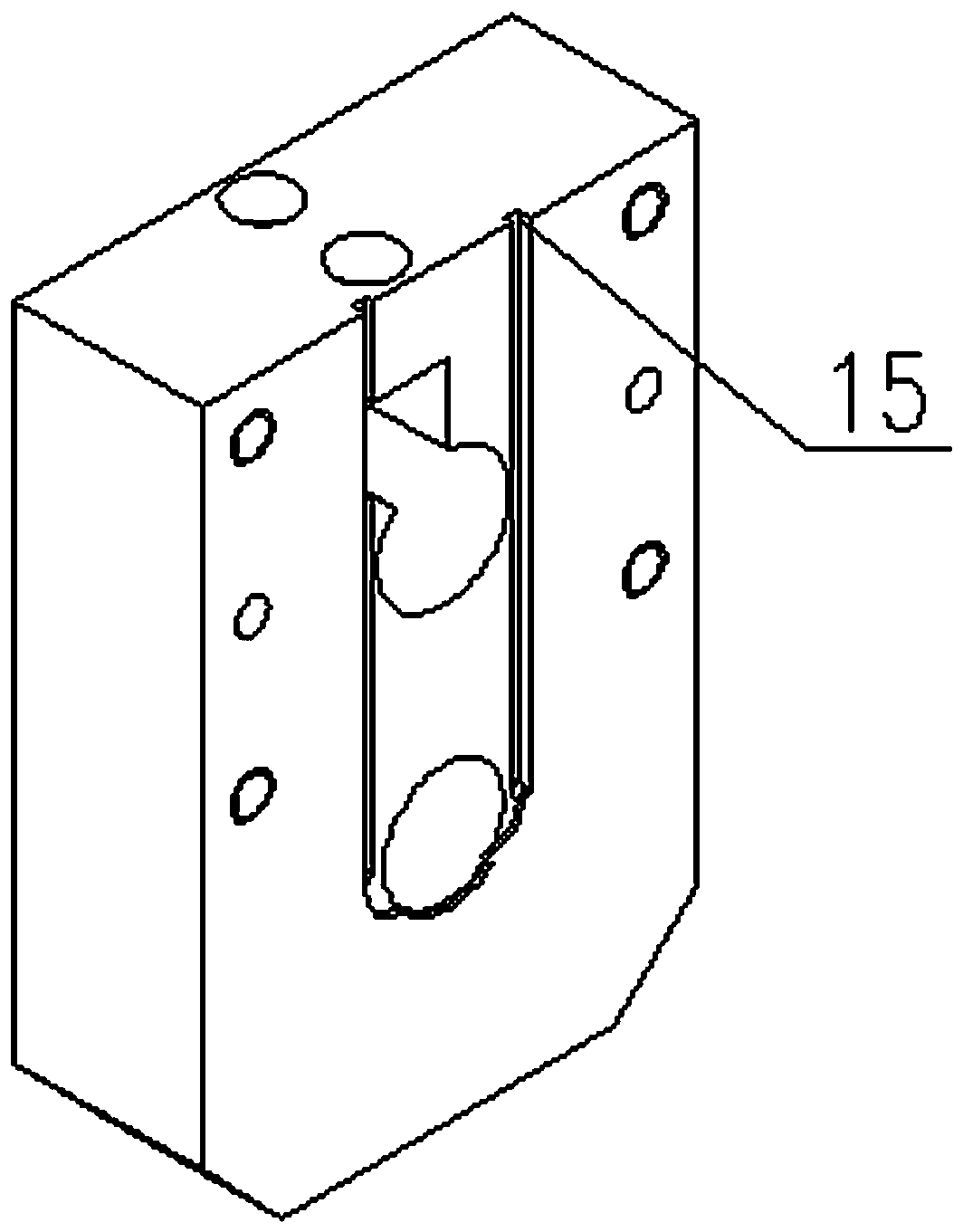

[0027] Such as figure 1 , 2 The shown automatic press-fitting mechanism for retaining rings for idler shafts includes a vertically connected horizontal support plate 13 and a vertical connection seat 3. The top of the connection seat 3 is equipped with a power cylinder 1 through a connection assembly 2, and the piston of the power cylinder 1 is connected to There is a vertical insertion piece 4, a fixed seat 6 is provided in the middle section of the connecting seat 3, and a track groove 15 is arranged in the fixed seat 6. Snare shaft 11 and retaining ring storage shaft 8, the axes of retaining ring sleeve shaft 11 and retaining ring storage shaft 8 are parallel to each other and located on the same vertical plane, the stroke surface (ie left side) of the inserting piece 4 and the shaft of retaining ring storage shaft 8 The end face (that is, the right en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com