Walnut cold-pressing expeller

A cold press, walnut technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of the destruction of walnut oil nutrients, the inability to do deep processing of by-products, and the inability to make high-grade edible oil, etc., to achieve simple use and low labor intensity of equipment operations. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

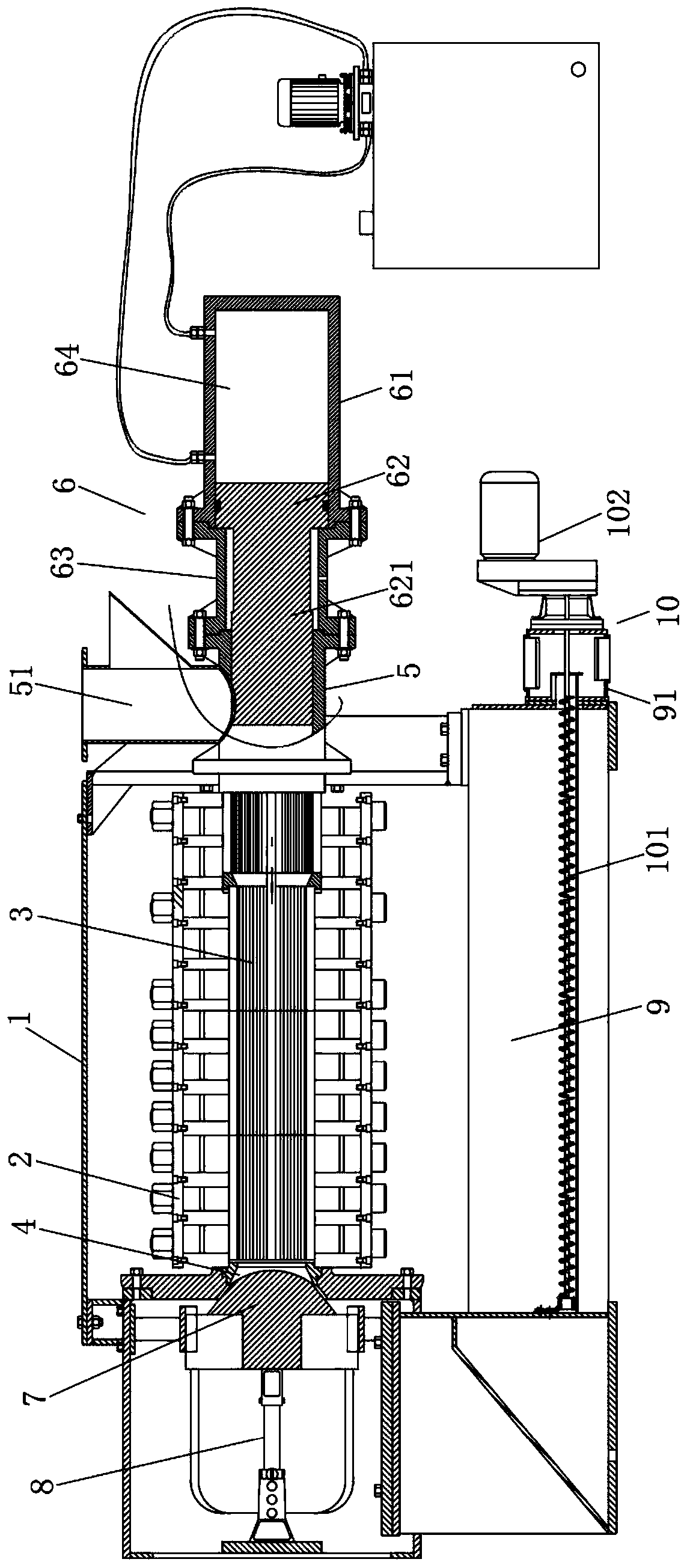

[0030] Example: such as figure 1 As shown, the walnut cold press of this embodiment includes a squeeze cage 2, which is horizontally installed on the frame 1, and a plurality of squeeze cages respectively extending to the openings at both ends are installed on its inner wall along its circumference. Bar 3, a plurality of the above-mentioned squeeze bars 3 are evenly spaced along the circumferential direction of the above-mentioned squeeze cage 2, one end of the above-mentioned squeeze bars 3 together constitutes a feed port, and the other end is connected and communicated with a slag discharge port 4; the feed channel 5. The feed channel 5 is installed on the frame 1 along the axial direction of the press cage 2, one end of which is connected and communicated with the feed port, and a feed port 51 is provided on the upper part; the pushing cold pressing mechanism 6, the pushing The material cold pressing mechanism 6 is installed on the other end of the above-mentioned feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com