Automatic steel ball press machine

A pressing machine and fully automatic technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of single applicable occasions and insufficient assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

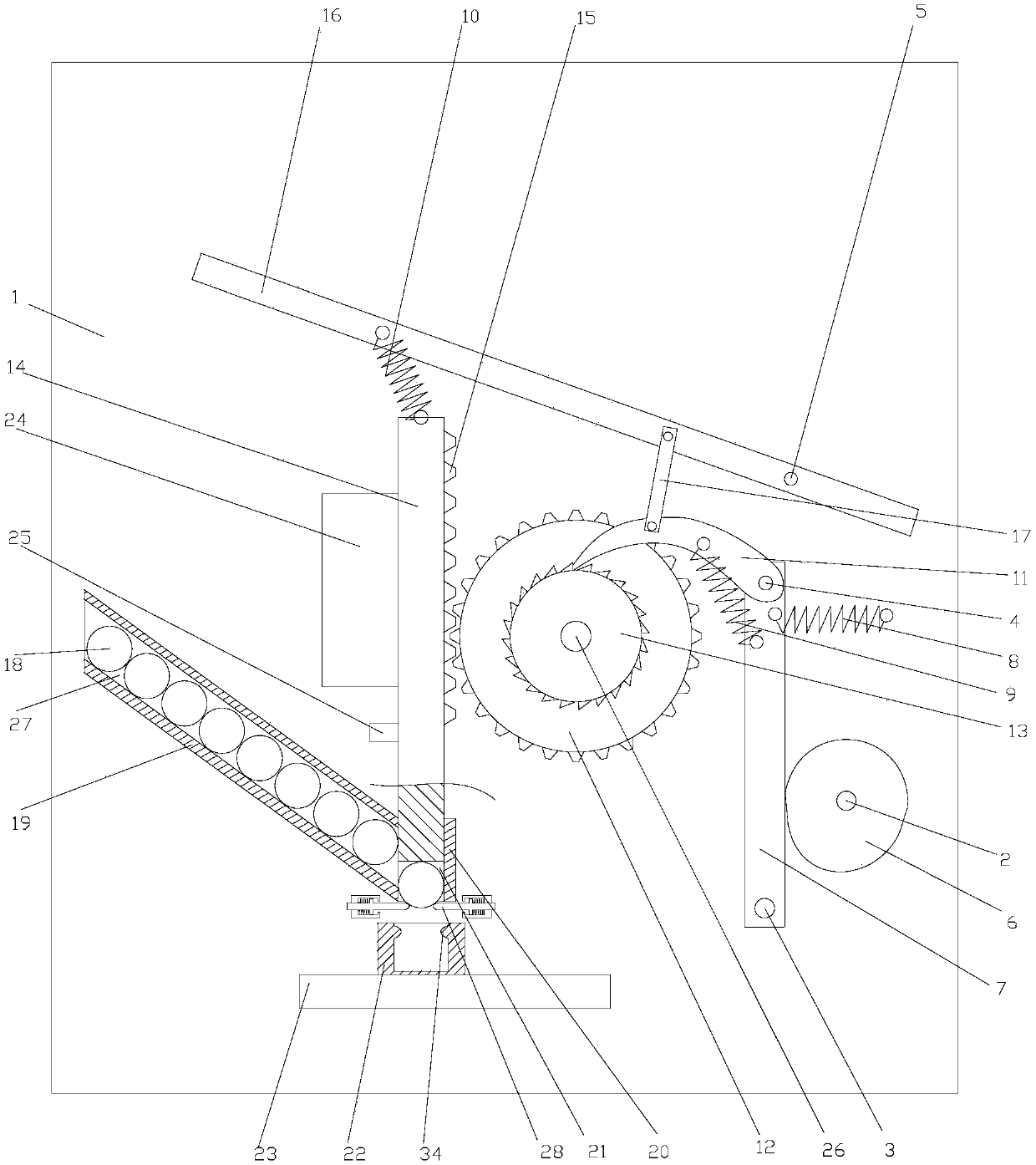

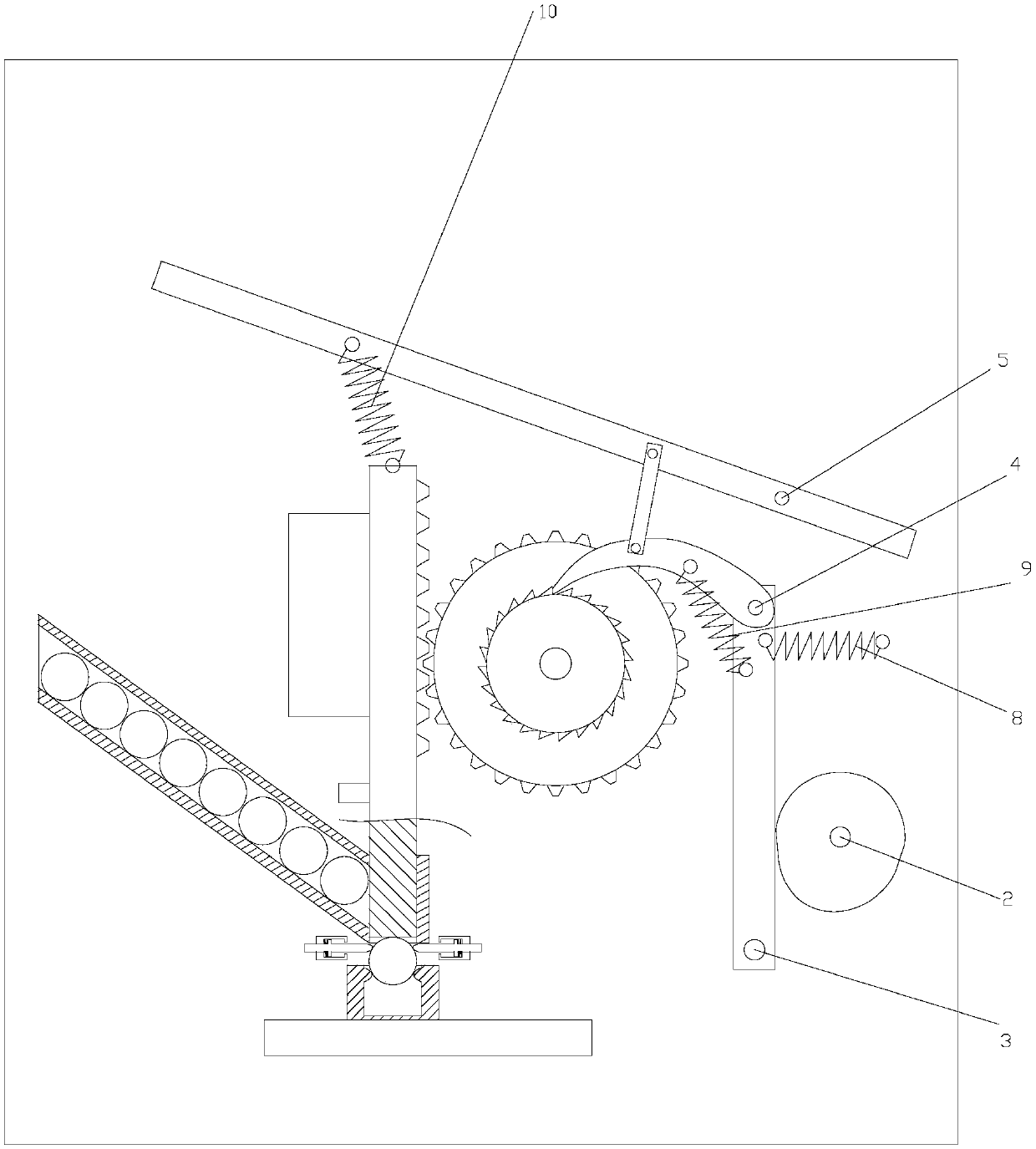

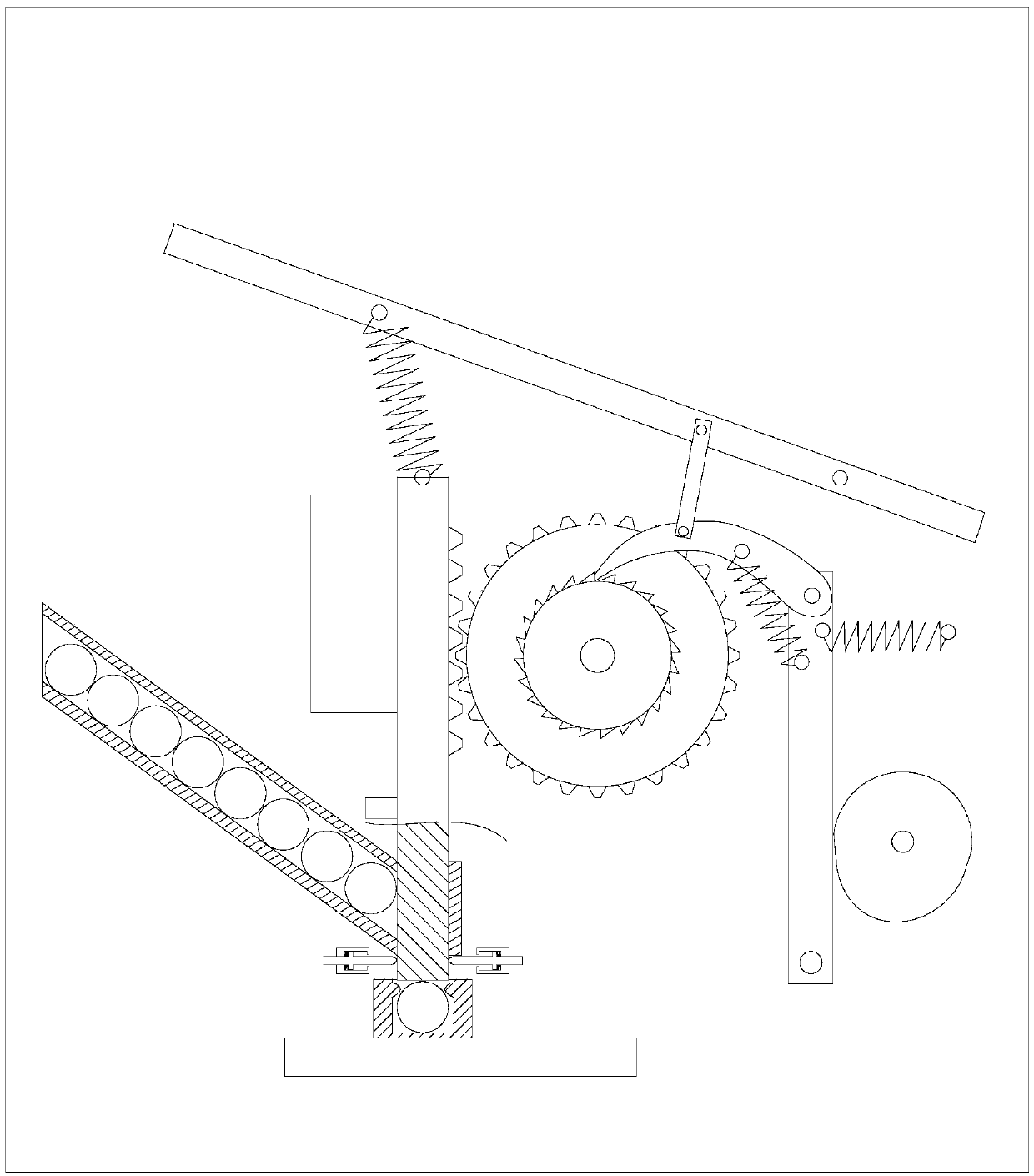

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] As shown in the figure, the automatic steel ball pressing machine of the present invention includes a base 1, the base 1 is connected with a cam 6 through the rotation of the first hinge point 2, and the base 1 is provided with a power device for driving the rotation of the cam 6, the power device It can be a motor or a motor. The output end of the motor or motor is connected to the cam 6 to drive the cam 6 to rotate on the base 1; There is a first tension spring 8 for pulling the rotating plate 7 against the outer profile of the cam 6; the upper end of the rotating plate 7 is connected with a pawl 11 through the third hinge point 4, and a gear 12 is connected with the base 1. , the end surface of the gear 12 is provided with a ratchet 13 for engaging or disengaging with the ratchet 11, and a second extension spring 9 for pulling the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com