Continuous pressing and discharging equipment for non-discoloring artificial flowers and leaves

A technology for imitating flowers and leaves, applied in artificial flowers, separating solids from solids by air flow, and separating solids, etc., can solve the problems of low pressing efficiency, uneven pressing effect, and poor uniformity of pressed products, etc. The effect of improving the pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

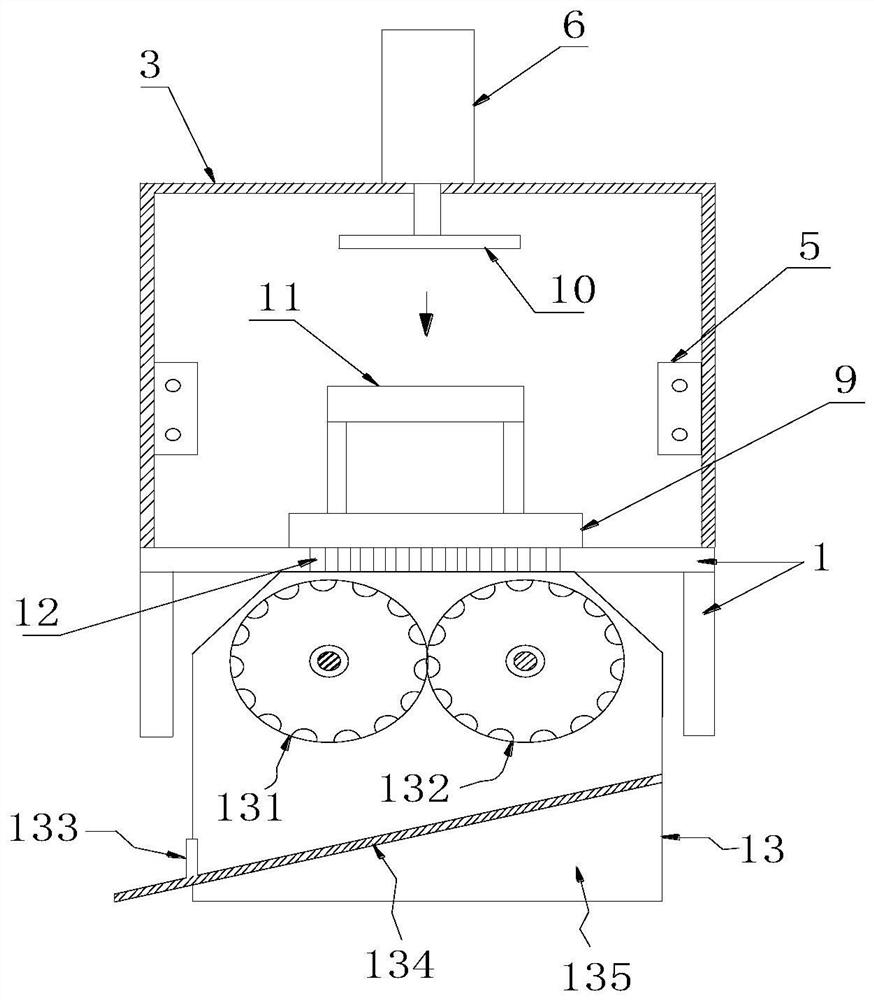

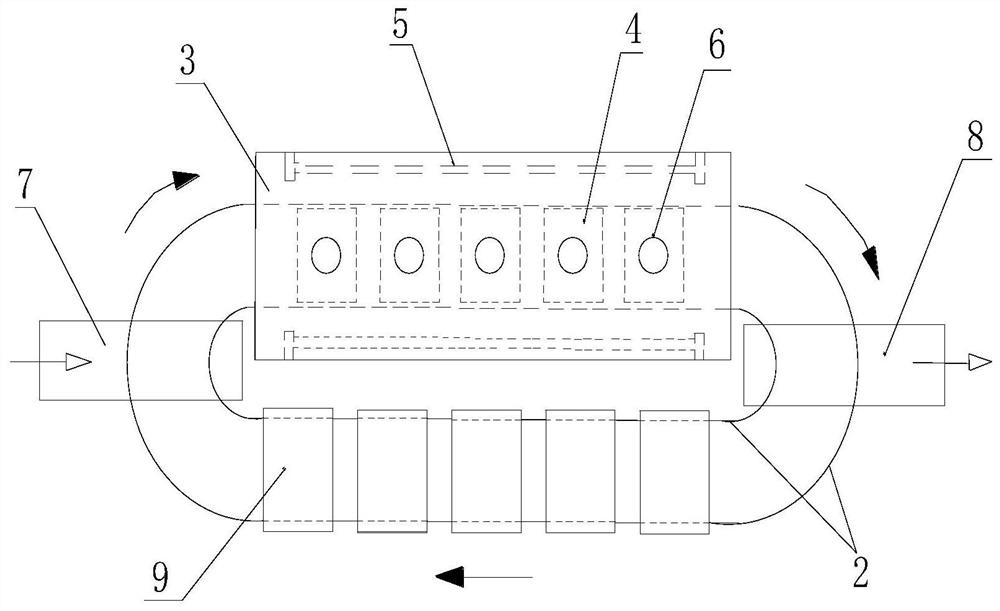

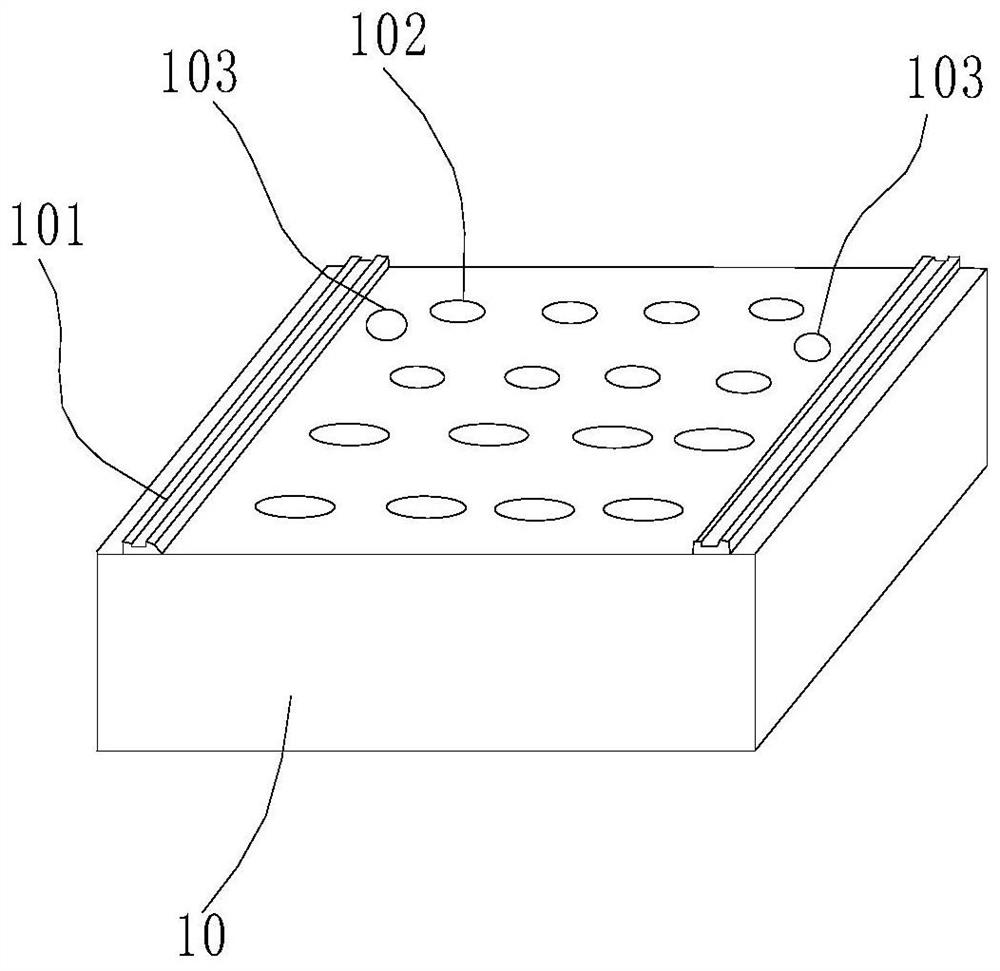

[0029] refer to Figure 1-Figure 6 , a kind of discoloration-changing simulated flower blade continuous pressing and discharging equipment of the present embodiment includes a frame 1, a rotary conveyor chain 2, a furnace body 3, an upper mold 10, a lower mold 11, and a collecting tray 13.

[0030] The frame 1 is used to carry the weight of the furnace body 3 and the upper and lower molds, and is placed on both sides of the conveying channel of the rotary conveying chain 2 .

[0031] The furnace body 3 is arranged above the frame 1; the furnace body 3 provides a high-temperature environment for pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com