Method for welding heterogenous system aluminum alloy through electron beams

A technology of electron beam welding and aluminum alloy, which is applied in the direction of electron beam welding equipment, welding equipment, welding equipment, etc., can solve the problems of poor weld forming quality and poor mechanical properties of joints, so as to improve the structure and performance of joints, weld seam Good molding quality and reduced unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0037] The electron beam welding machine used in the test is a CT4 electron beam welding gun produced by a French company. It is a three-stage gun with an indirect heating cathode. The cathode heating method is filament electron bombardment heating. The cathode material is tungsten and the output power is 15KW.

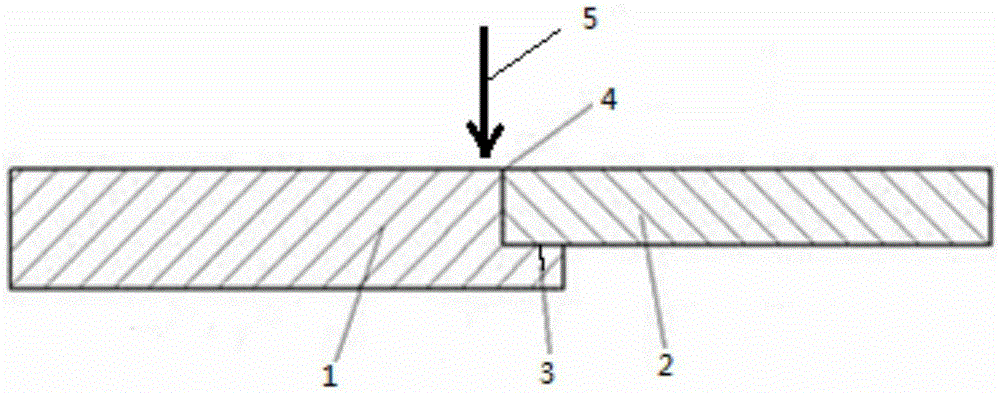

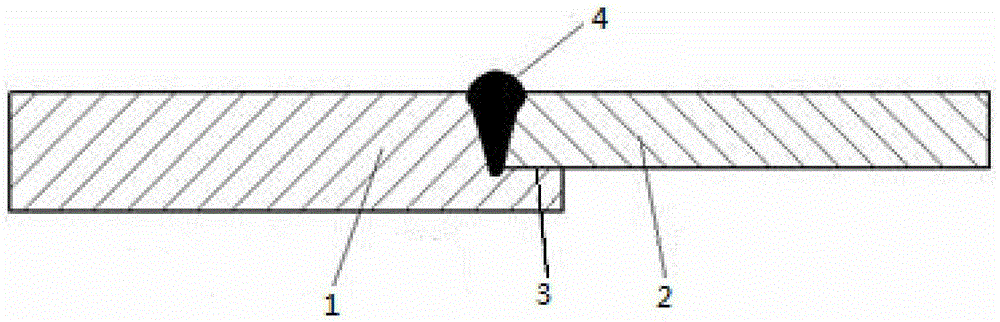

[0038] 1. ZL114A / 5A06 material 1mm thick structure flat plate butt welding:

[0039] The welding specifications are as follows: the joint is designed as a lock bottom butt joint form, the ZL114A side has a lock bottom 2mm, the electron beam acceleration voltage is set to 30kV, the electron beam current is 20mA, and the electron beam is located on the ZL114A side 0.1mm from the center of the weld , The welding speed is 1.2m / min, and the defocus amount is JSUR (surface focus) -0.02A.

[0040] The flat plate butt weld obtained by the above welding specifications has good shape, uniform corrugation, good gas protection, no cracks, incomplete penetration, and lack of fusion insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com