Multistage crusher

A technology of crushers and crushing chambers, which is applied in the direction of grain processing, etc., and can solve problems such as the reduction of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

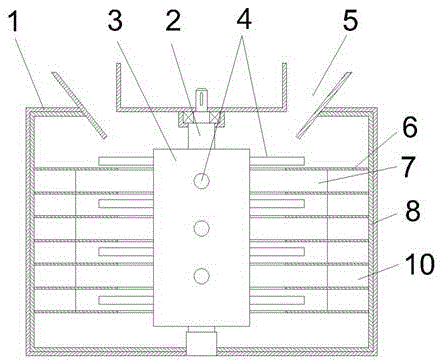

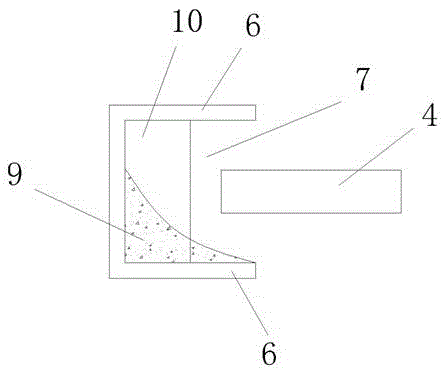

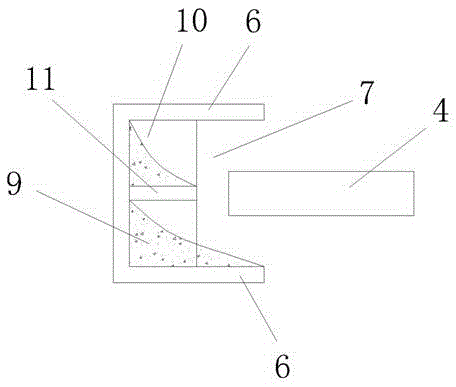

[0016] Such as figure 1 and figure 2 Shown is the first specific embodiment of the multi-stage crusher of the present invention, the crusher includes a cylindrical shell 1, the upper end of the shell 1 is provided with a feed port 5, and the lower end of the shell 1 is provided with a discharge port. In this embodiment, the lower end of the housing 1 adopts an open and grate-free outlet, and the inner wall of the housing 1 is covered with a layer of lining board 8, and the lining board 8 is provided with a multi-layer annular partition 6 extending horizontally inward. The two partitions 6 and the liner 8 enclose a crushing chamber 7 with only an open inner ring surface, and at least one baffle 10 is vertically arranged in the crushing chamber 7; a central rotating shaft 2 extending up and down is installed in the shell 1, The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com