A vertical coaxial biomass crushing and forming integrated device

A biomass and coaxial technology, applied in the direction of biofuels, solid fuels, waste fuels, etc., can solve problems such as difficult crushing and transportation, abnormal reactors, low energy density, etc., to prolong the use time, increase adaptability, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

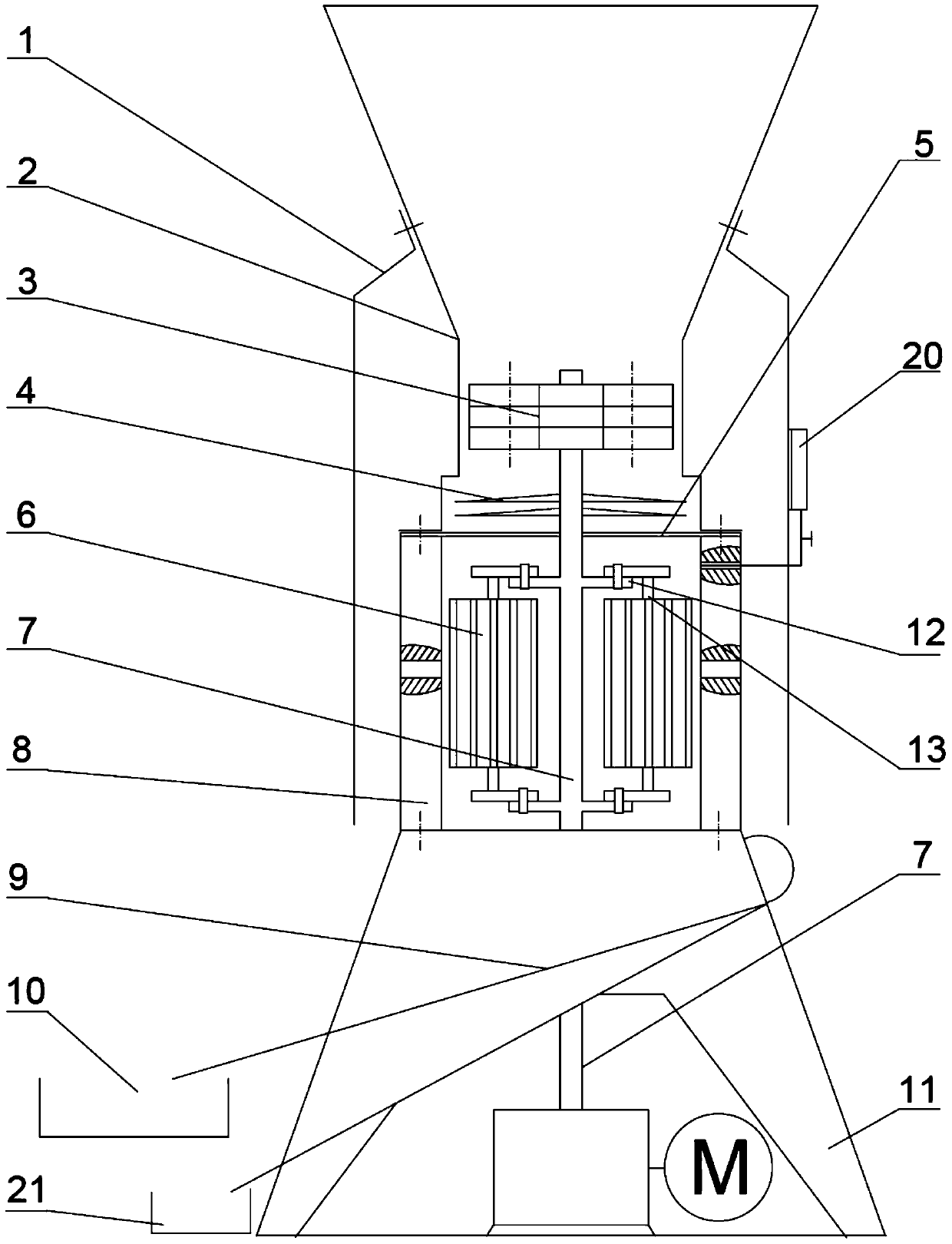

[0020] (Example 1) see figure 1 , 3 、4

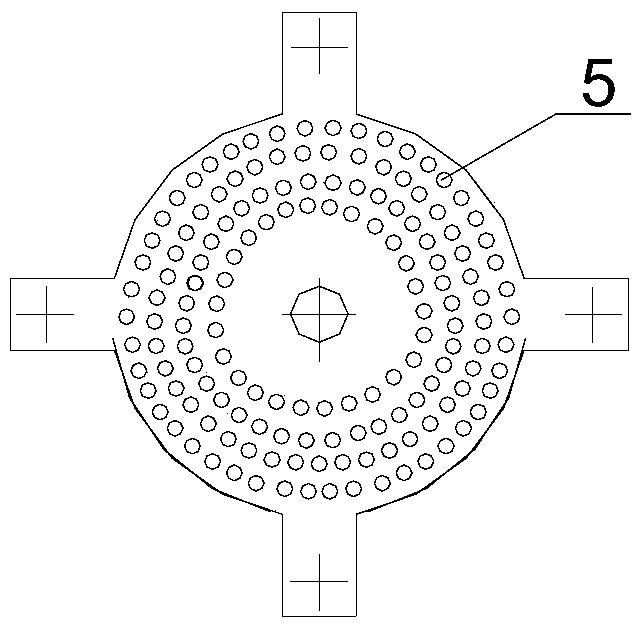

[0021] The vertical coaxial biomass crushing and molding integrated device of the present invention has a shell 1 on the outside and a cavity inside, and the upper part of the cavity is a funnel-shaped biomass feed hopper 2; the bottom of the biomass feed hopper 2 is the present invention. The middle part of the device is equipped with hammer crusher 3, knife crusher 4, material distribution plate 5, and forming rotor system in sequence, wherein hammer crusher 3 and knife crusher 4 are fixedly set on the forming rotor main shaft 7, and the material distribution plate 5 as image 3Described is a circular plate with four protruding connecting parts, there is no hole in the center of the circular plate, and there are holes in the periphery. The forming rotor main shaft 7 is located at the center of the inner cavity of the housing 1 and runs through the housing 1. It is driven by the motor at the lower part of the device. The ring formin...

Embodiment 2

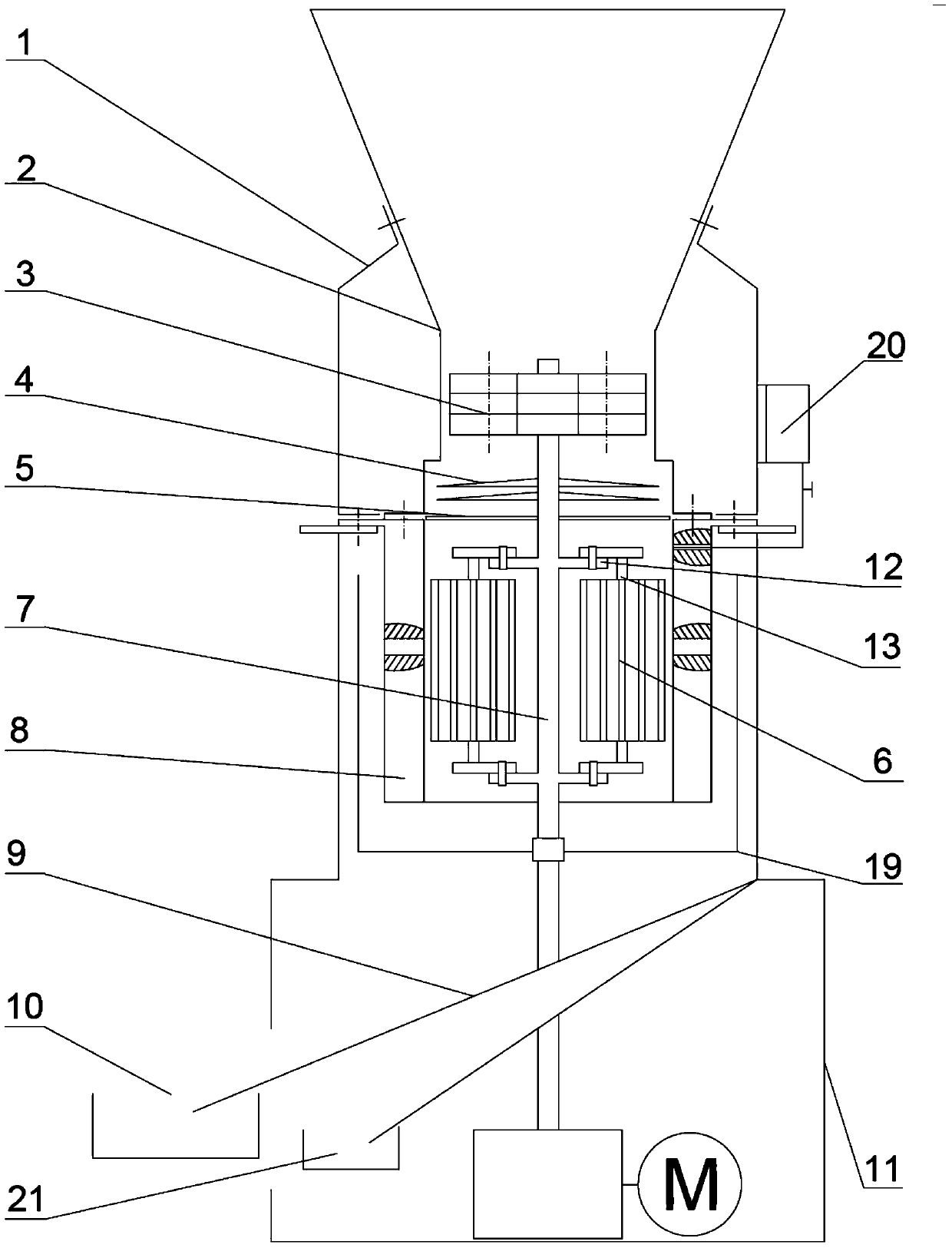

[0022] (Example 2) see figure 2 , 5 、6

[0023] The vertical coaxial biomass crushing and molding integrated device of the present invention has a shell 1 on the outside and a cavity inside; the upper part of the cavity is a funnel-shaped biomass feed hopper 2; the bottom of the biomass feed hopper 2 is the present invention The middle part of the device is equipped with hammer crusher 3, knife crusher 4, material distribution plate 5 and forming rotor system in sequence, among which hammer crusher 3, knife crusher 4 and material distribution plate 5 are fixedly set on the main shaft of forming rotor 7, the material distribution plate 5 is as Figure 5 A circular plate with no holes in the center and holes in the periphery. The forming rotor main shaft 7 is located at the center of the inner cavity of the housing 1 and the device base 11, and is driven by the motor at the lower part of the device. The annular forming mold 8 is located outside the forming rotor system, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com