Filter cloth online circulation washing system and method of titanium dioxide water washing leaf filter

A technology of circulating washing and leaf filter, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of poor soaking effect, long time required for hydrofluoric acid soaking, affecting production efficiency, etc. Washing time, improving titanium dioxide production efficiency, and the effect of short washing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

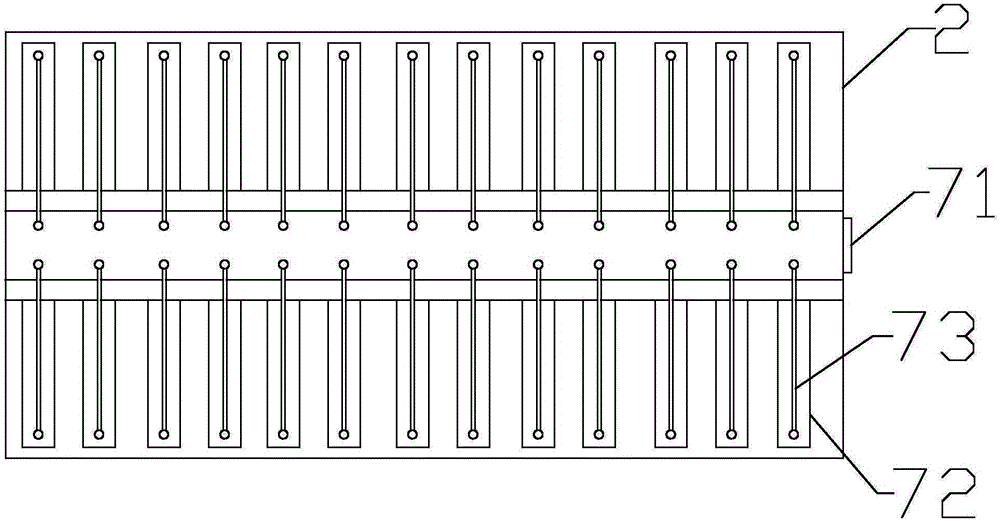

Image

Examples

Embodiment 1

[0024] Use the above-mentioned online circulation washing system to wash the filter cloth of the titanium white water-washed leaf filter. The concentration of hydrofluoric acid in the washing liquid used is 3%. First, place the leaf filter on the filter cloth washing pool to ensure that the filter cloth and filter plate are placed on the In the cloth washing tank, start the hydrofluoric acid pump. When the filter cloth washing tank is filled with 1 / 2 liquid, start the vacuum pump. After the system runs for 3.6 hours, stop the pump and stop washing. The washing effect is: the clogged area of the filter cloth filter hole is 0.3%.

Embodiment 2

[0026] Use the above-mentioned online circulation washing system to wash the filter cloth of the titanium white water-washed leaf filter. The concentration of hydrofluoric acid in the washing liquid used is 3%. First, place the leaf filter on the filter cloth washing pool to ensure that the filter cloth and filter plate are placed on the In the cloth washing tank, start the hydrofluoric acid pump, and when the filter cloth washing tank is filled with 2 / 3 of the liquid, start the vacuum pump, and stop the pump and wash after the system runs for 3 hours. The washing effect is: the clogging area of the filter cloth filter hole is 0.2%.

Embodiment 3

[0028] Soaking and washing, the concentration of hydrofluoric acid in the washing liquid is 3%, the filter cloth and filter plate of the leaf filter are soaked in the hydrofluoric acid washing pool for 5.5 hours and then taken out. The washing effect is: the blocked area of the filter cloth filter hole is 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com