Flow-divided cutting fluid filter unit

A filter device and cutting fluid technology, applied in the direction of filtration separation, membrane filter, mobile filter element filter, etc., can solve the problems of reduced utilization rate of cutting fluid, poor filtering effect, waste of filter net, etc., to promote flow and Filter, improve filter effect, keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

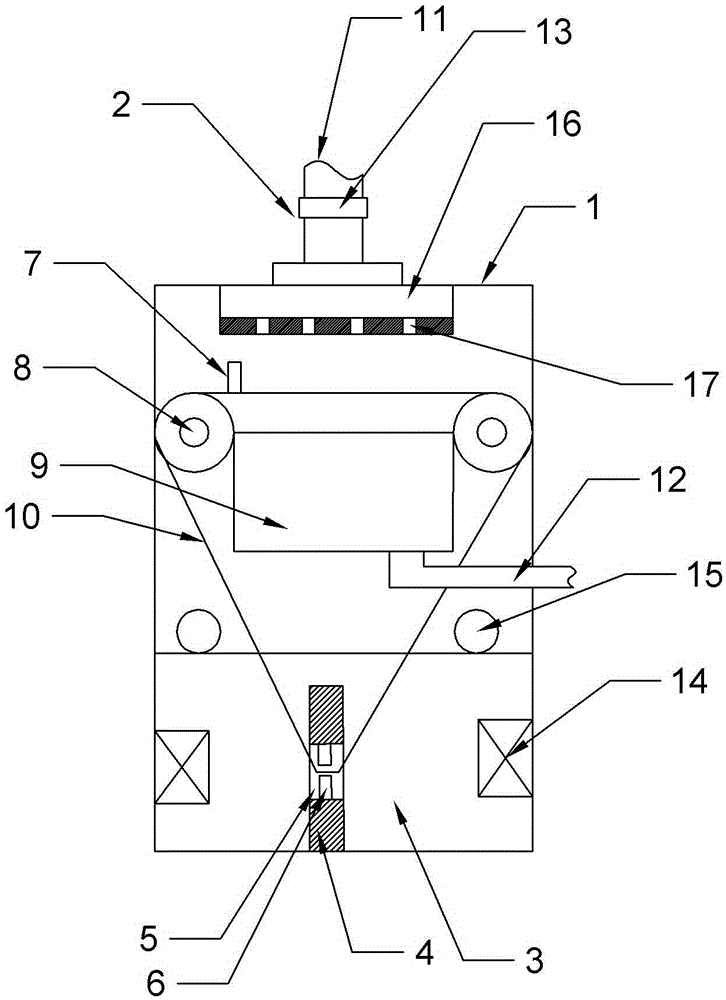

[0015] Such as figure 1 As shown, the split-flow cutting fluid filtering device includes a casing 1, a filtering mechanism and a cleaning mechanism. The filtering mechanism is located in the casing 1, and the cleaning mechanism is located below the filtering mechanism. 2. A diversion plate 16 is arranged on the lower surface, and a plurality of diversion holes 17 are arranged on the lower surface of the diversion plate 16. The cleaning mechanism includes a cleaning tank 3 and a cleaning block 4. The cleaning block 4 is vertically arranged at the bottom of the cleaning tank 3. A horizontal through hole 5 is arranged in the middle of the cleaning block 4. The upper and lower surfaces of the through hole 5 are oppositely provided with a scraper 6. The filter mechanism includes a scraper 7, two drums 8, a collection tank 9 and a filter screen 10, the two drums 8 are symmetrically located on both sides of the casing 1, the filter screen 10 includes a filter section and a cleaning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com