Low-sodium seasoning peptide salt

A technology of taste peptide and sodium chloride, applied in the field of compound condiments, can solve problems such as high sodium and low potassium, and achieve the effect of reducing dosage, good quality and human health conditioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

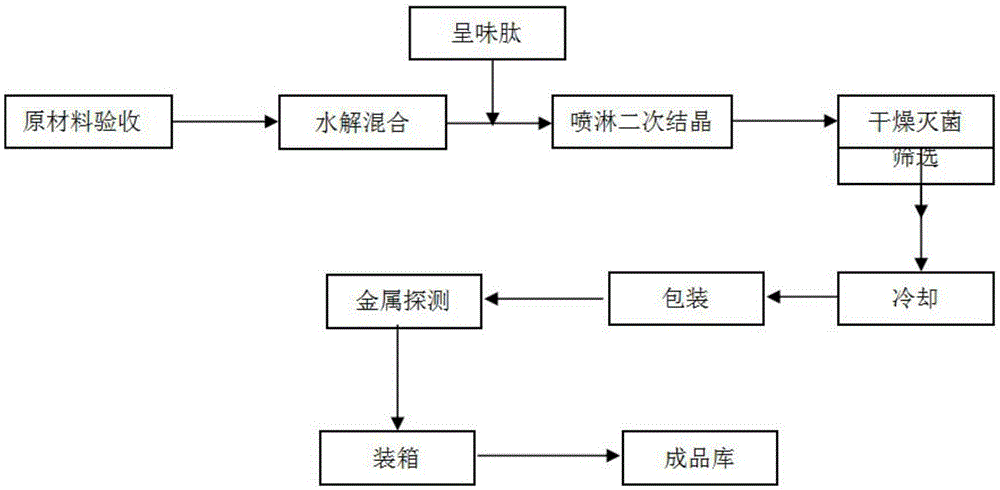

Method used

Image

Examples

Embodiment 1

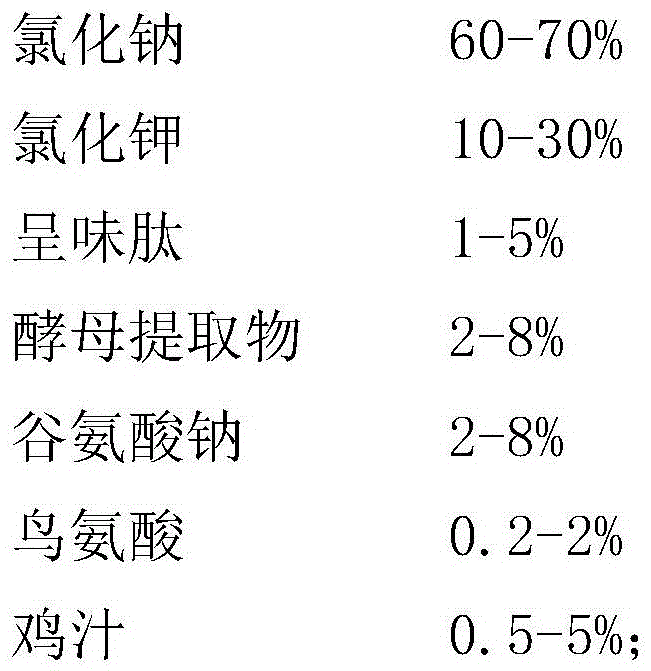

[0040] A low-sodium seasoning peptide salt made from the following raw materials in percentage by weight:

[0041]

[0042] The specific preparation method is as follows:

[0043] 1) Check and accept sodium chloride, potassium chloride, taste peptide, yeast extract, sodium glutamate, ornithine and chicken juice according to the above proportions;

[0044] 2) Dissolve sodium chloride, potassium chloride, yeast extract, sodium glutamate, ornithine and chicken juice in deionized water, heat up to 85°C, stir at a speed of 300r / min until completely dissolved, and prepare A solution with a dry matter weight concentration of 35%-45%;

[0045] 3) After the solution is cooled to 40°C, add flavor peptide under stirring at a speed of 300r / min, and after stirring for 10 minutes at a speed of 300r / min, immediately use a centrifugal spray drying tower for spray drying to crystallize and dry The air inlet temperature of the tower is 145-155°C, and the outlet air temperature is 95-105°C ...

Embodiment 2

[0050] A low-sodium seasoning peptide salt made from the following raw materials in percentage by weight:

[0051]

[0052]

[0053] A method for preparing the above-mentioned low-sodium seasoning peptide salt, the specific steps are as follows:

[0054] 1) Check and accept sodium chloride, potassium chloride, taste peptide, yeast extract, sodium glutamate, ornithine and chicken juice according to the above proportions;

[0055] 2) Dissolve sodium chloride, potassium chloride, yeast extract, sodium glutamate, ornithine and chicken juice in deionized water, heat up to 85°C, stir at a speed of 300r / min until completely dissolved, and prepare A solution with a dry matter weight concentration of 35%-45%;

[0056] 3) After the solution is cooled to 40°C, add flavor peptide under stirring at a speed of 300r / min, and after stirring for 10 minutes at a speed of 300r / min, immediately use a centrifugal spray drying tower for spray drying to crystallize and dry The air inlet temp...

Embodiment 3

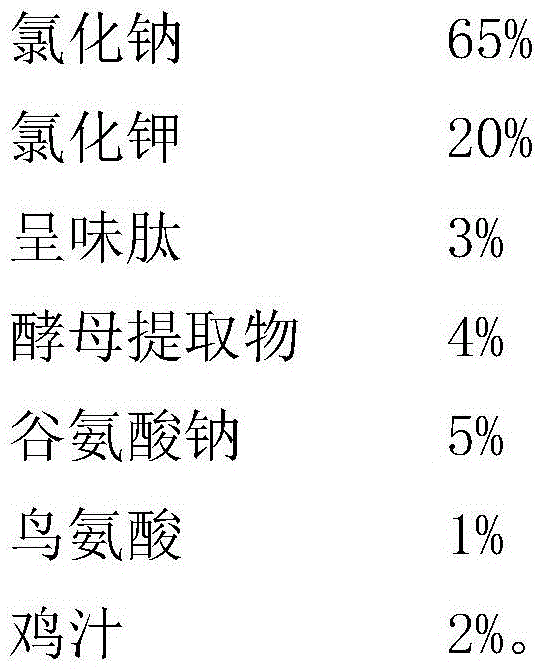

[0068] A low-sodium seasoning peptide salt made from the following raw materials in percentage by weight:

[0069]

[0070] A method for preparing the above-mentioned low-sodium seasoning peptide salt, the specific steps are as follows:

[0071] 1) Check and accept sodium chloride, potassium chloride, taste peptide, yeast extract, sodium glutamate, ornithine and chicken juice according to the above proportions;

[0072] 2) Dissolve sodium chloride, potassium chloride, yeast extract, sodium glutamate, ornithine and chicken juice in deionized water, heat up to 85°C, stir at a speed of 300r / min until completely dissolved, and prepare A solution with a dry matter weight concentration of 35%-45%;

[0073] 3) After the solution is cooled to 40°C, add flavor peptide under stirring at a speed of 300r / min, and after stirring for 10 minutes at a speed of 300r / min, immediately use a centrifugal spray drying tower for spray drying to crystallize and dry The air inlet temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com