Synchronous sewage denitrification and desulphuration method for microbial fuel cell

A technology of fuel cells and microorganisms, applied in the field of sewage biological denitrification and desulfurization, can solve the problems of increased costs and inability to recover the energy of nitrogen and sulfur pollutants, and achieve the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

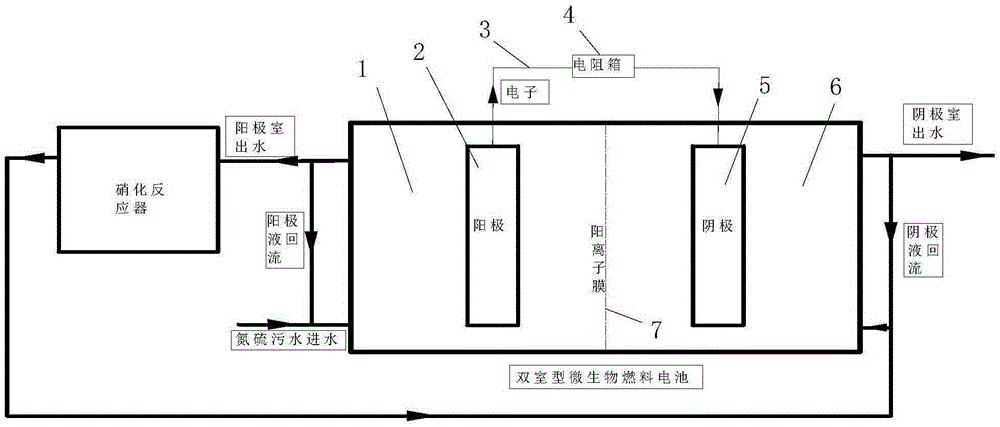

Image

Examples

Embodiment 1

[0039] The cuboid double-chamber microbial fuel cell used in this test has a total effective volume of 300mL, of which the anode chamber and cathode chamber are each 150mL, and graphite brush fillers are hung inside as electrodes. The supernatant was hydromixed. Before the operation of the microbial fuel cell, the graphite brush is soaked in anaerobic sludge to absorb microorganisms. After a period of operation, the corresponding microorganisms can be propagated and enriched on the anode and cathode graphite brushes. The dual-chamber microbial fuel cell operates at 30°C, the resistance of the external circuit is set to 100Ω, and the hydraulic retention time of sewage is 2.8h. The specific operation is as follows:

[0040] 1) The sewage containing sulfide (56mgS / L) and ammonia nitrogen (17mgN / L) is injected into the anode chamber of the microbial fuel cell through the water inlet pump.

[0041]2) The sulfide in the anode chamber is oxidized through spontaneous electrochemistr...

Embodiment 2

[0047] The cuboid double-chamber microbial fuel cell used in this test has a total effective volume of 300mL, of which the anode chamber and cathode chamber are each 150mL, and graphite brush fillers are hung inside as electrodes. The supernatant was hydromixed. Before the operation of the microbial fuel cell, the graphite brush is soaked in anaerobic sludge to absorb microorganisms. After a period of operation, the corresponding microorganisms can be propagated and enriched on the anode and cathode graphite brushes. The dual-chamber microbial fuel cell operates at 30°C, the resistance of the external circuit is set to 100Ω, and the hydraulic retention time of sewage is 2.8h. The specific operation is as follows:

[0048] 1) The sewage containing sulfide (126mgS / L) and ammonia nitrogen (17mgN / L) is injected into the anode chamber of the microbial fuel cell through the water inlet pump.

[0049] 2) The sulfide in the anode chamber is oxidized through spontaneous electrochemis...

Embodiment 3

[0055] The cuboid double-chamber microbial fuel cell used in this test has a total effective volume of 300mL, of which the anode chamber and cathode chamber are each 150mL, and graphite brush fillers are hung inside as electrodes. The supernatant was hydromixed. Before the operation of the microbial fuel cell, the graphite brush is soaked in anaerobic sludge to absorb microorganisms. After a period of operation, the corresponding microorganisms can be propagated and enriched on the anode and cathode graphite brushes. The dual-chamber microbial fuel cell operates at 30°C, the resistance of the external circuit is set to 100Ω, and the hydraulic retention time of sewage is 2.8h. The specific operation is as follows:

[0056] 1) The sewage containing sulfide (185mgS / L) and ammonia nitrogen (17mgN / L) is injected into the anode chamber of the microbial fuel cell through the water inlet pump.

[0057] 2) The sulfide in the anode chamber is oxidized through spontaneous electrochemis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com