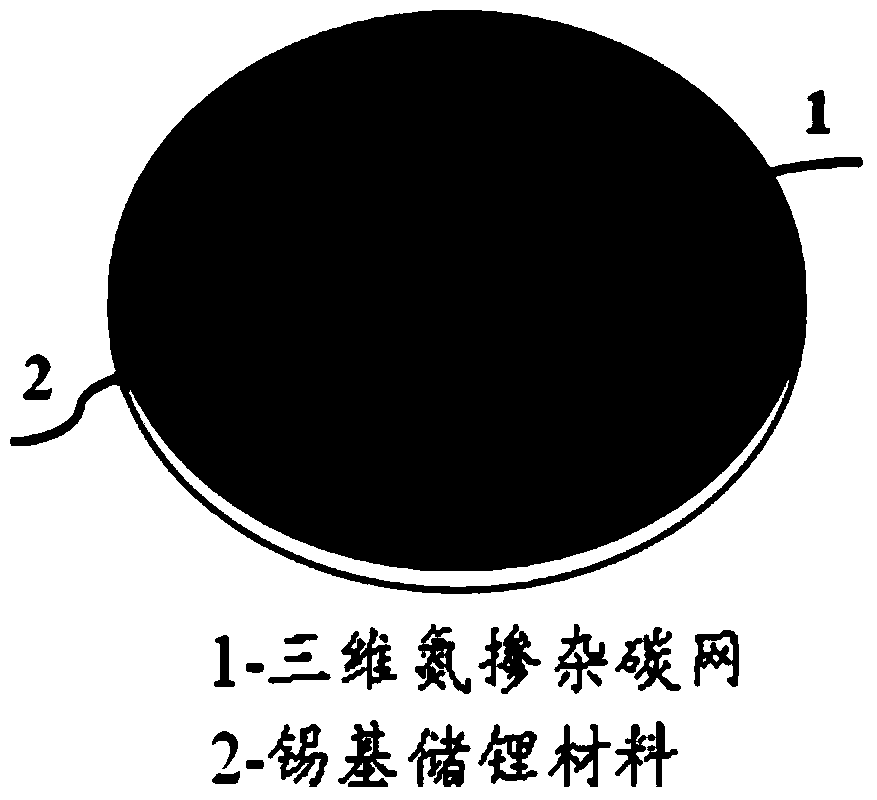

A kind of composite negative electrode material and its secondary battery

A negative electrode material and secondary battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of large volume change and poor rate performance, and achieve the effect of simple and convenient process, low cost, and improved charge transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Optionally, the step in the preparation method provided by the second aspect: the step of subjecting the second mixed solution to an incubation reaction to obtain a black precipitate specifically includes:

[0059] The second mixed solution was incubated at 0 to 5° C. for 1 to 24 hours and then filtered to obtain a black precipitate.

[0060] Optionally, the black precipitate is washed to neutrality and dried, the dried black precipitate is placed in a tube furnace, and the tube furnace where the black precipitate is placed is fed with The mixed gas mixture of heteroelement hydride and inert carrier gas, after sintering, obtains three-dimensional nitrogen-doped carbon materials including:

[0061] Wash the black precipitate with a hydrogen chloride solution to neutrality and dry it at 50 to 100°C for 1 to 24 hours, then place the dried black precipitate in a tube furnace, and place the black precipitate in the A mixed gas of hydride containing doping elements and inert...

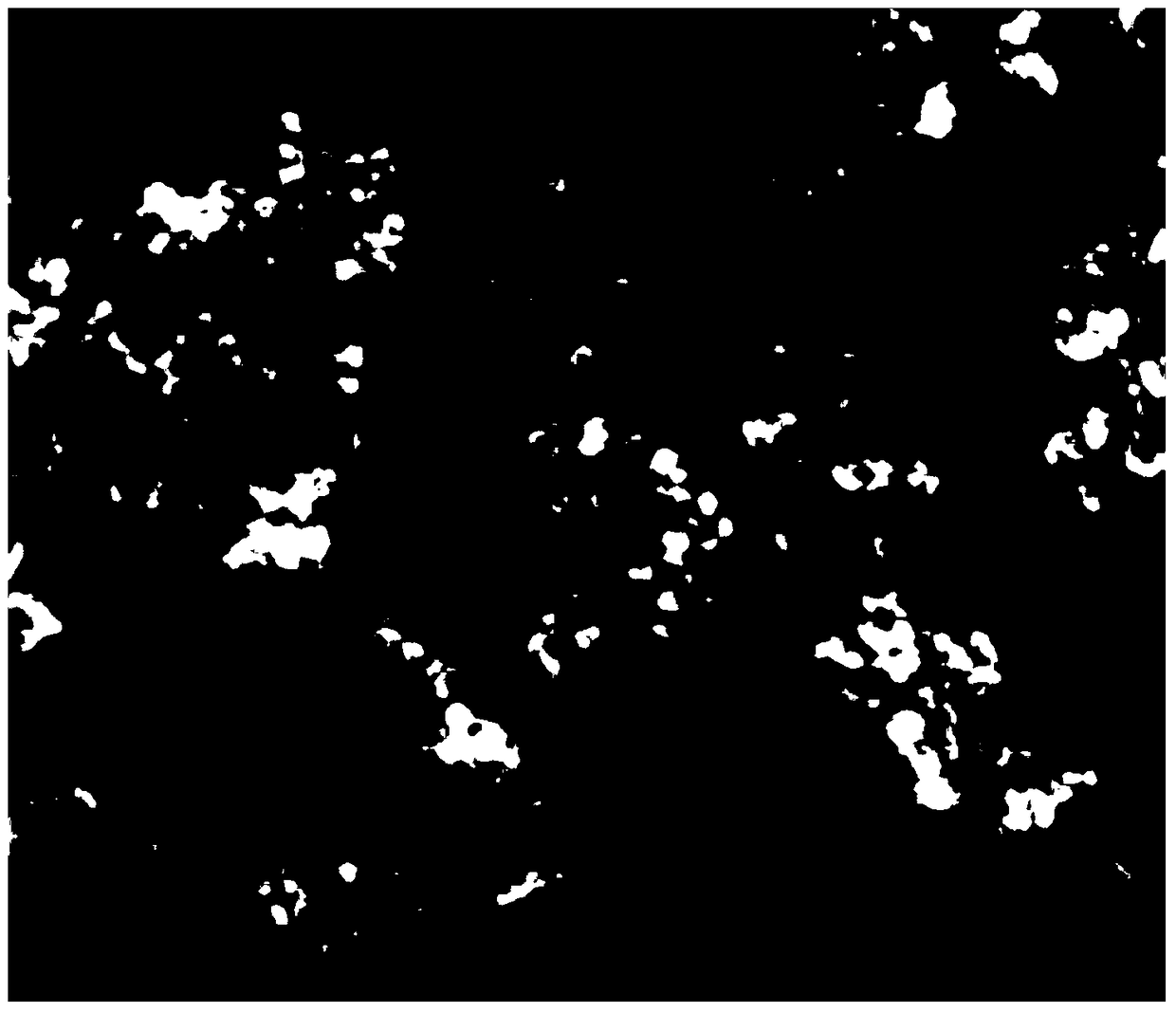

Embodiment 1

[0072] Preparation of three-dimensional nitrogen-doped carbon / tin composite anode material: after pyrolysis of polymers with C-N chemical bonds in the main chain, silicon active materials are loaded on the surface by chemical deposition method to obtain three-dimensional nitrogen-doped carbon / silicon composite anode material .

[0073] Specific steps are as follows:

[0074] The first step, cetyltrimethylammonium bromide (CTAB, (C 16 h 33 )N(CH 3 ) 3 Br, 7.3 g) was dissolved in HCl (120 mL, 1 mol / L) solution in an ice-water bath, dispersed uniformly by ultrasonic, then ammonium persulfate (APS, 13.7 g) was added to it, a white suspension was formed immediately, stirred After 0.5 hours, add pyrrole monomer (Py, 8.3 mL), incubate at 0-5 °C for 24 h, then filter, wash the obtained black precipitate with 1 mol / L HCl solution three times, and then wash with pure water Until the solution was colorless and neutral, the precipitate was then dried at 80°C for 24 hours, and finally...

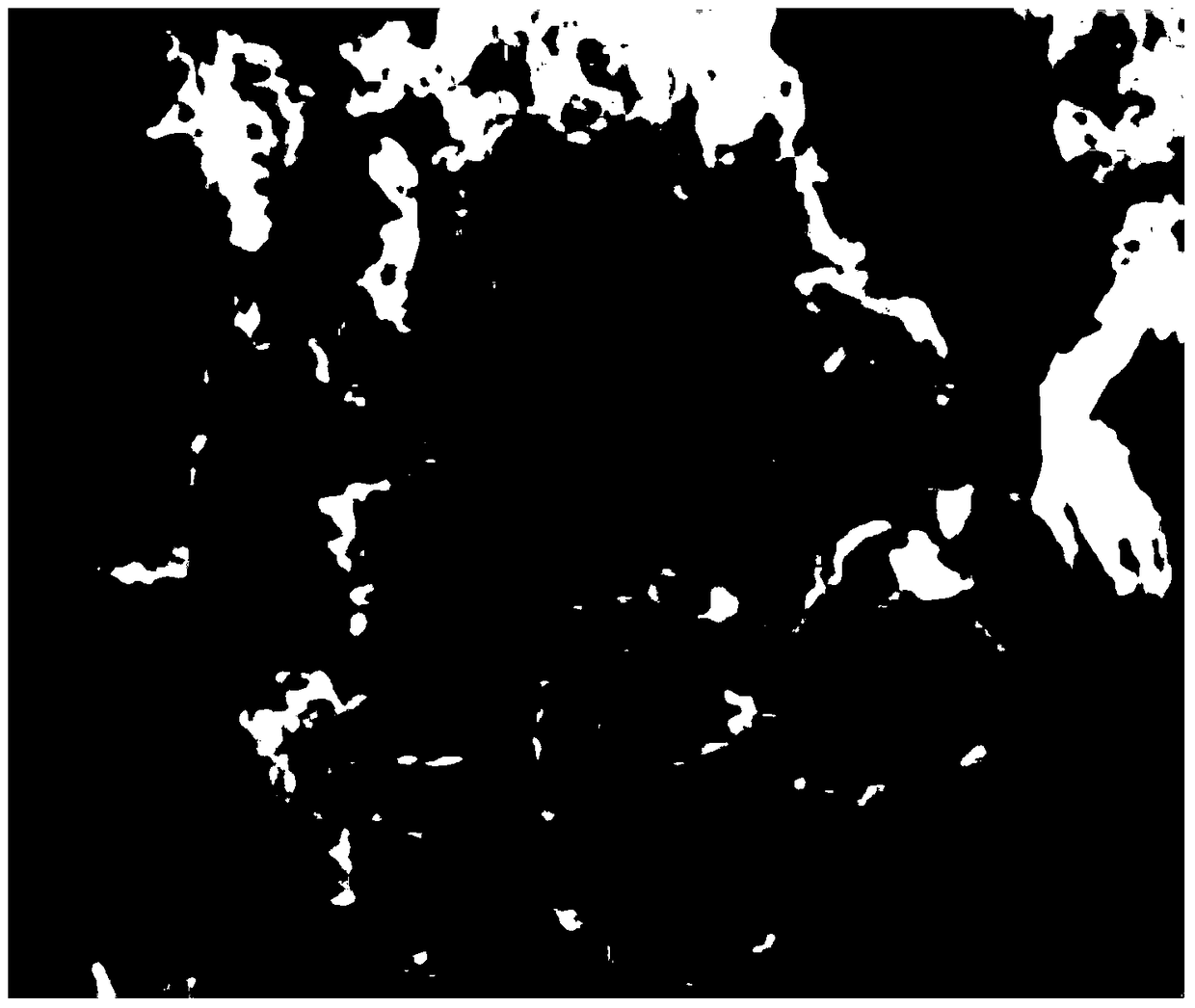

Embodiment 2

[0082] Preparation of three-dimensional nitrogen-doped carbon / tin composite anode materials: after pyrolysis of polymers with C-N chemical bonds in the main chain, nano-SnO is deposited on the surface by hydrothermal method 2 , to obtain a three-dimensional nitrogen-doped carbon / tin composite anode material.

[0083] Specific steps are as follows:

[0084] The first step, cetyltrimethylammonium bromide (CTAB, (C 16 h 33 )N(CH 3 ) 3 Br, 7.3 g) was dissolved in HCl (120 mL, 1 mol / L) solution in an ice-water bath, dispersed uniformly by ultrasonic, then ammonium persulfate (APS, 13.7 g) was added to it, a white suspension was formed immediately, stirred After 0.5 hours, add pyrrole monomer (Py, 8.3 mL), incubate at 0-5 °C for 24 h, then filter, wash the obtained black precipitate with 1 mol / L HCl solution three times, and then wash with pure water Until the solution was colorless and neutral, the precipitate was then dried at 80°C for 24 hours, and finally the dried precipit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com