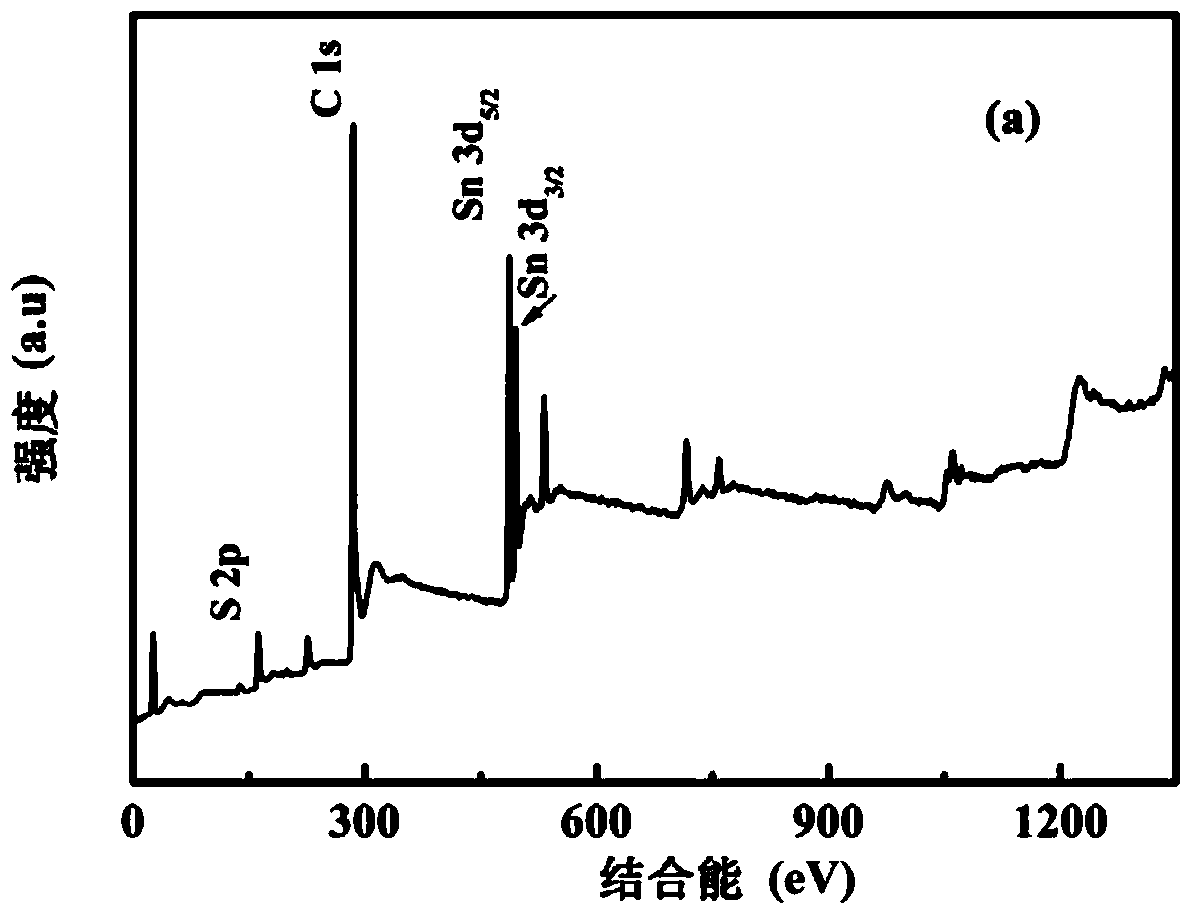

sns2-c nanocomposite negative electrode material and its preparation method and application

A nano-composite and negative electrode material technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high production cost, low output, complicated preparation process, etc. The effect of specific surface area and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment prepares a kind of SnS 2 -C nanocomposite anode material, in which SnS 2 The mass ratio with C is 2:1, and the specific steps are as follows:

[0046] (1) Weighing SnS 2 Powder (purity 99% and particle size 40-60μm) 4g, at the same time select 200g stainless steel metal grinding balls (ball material ratio is 50:1), put them into a 250ml stainless steel grinding tank together, fill in 1 bar of argon (Ar) for Protection; the ball mill jar is placed on the ball mill for the first ball mill to obtain the SnS after ball milling 2 Powder, wherein the ball milling speed is 400rpm, and the ball milling time is 40h.

[0047] (2) SnS after ball milling 2 Add glucose aqueous solution to powder, wherein glucose is 5g. At the same time, 180 grams of stainless steel metal grinding balls (ball-to-material ratio is 20:1) are put into a 250ml stainless steel grinding tank; The time is 30h.

[0048] (3) the mixture obtained in step (2) is dried in an oven, and the ...

Embodiment 2

[0057] This embodiment prepares a kind of SnS 2 -C nanocomposite anode material, in which SnS 2 The mass ratio with C is 1:1, and the specific steps are as follows:

[0058] (1) Weighing SnS 2 4g of powder (purity 99% and particle size 40-60μm), and 120g of stainless steel metal grinding balls (ball-to-material ratio: 30:1) were selected and put into a 250ml stainless steel grinding tank together, and filled with 1 bar of argon (Ar) for protection; Put the ball mill jar on the ball mill for the first ball mill to obtain the SnS after ball milling 2 Powder, wherein the ball milling speed is 500rpm, and the ball milling time is 40h.

[0059] (2) SnS after ball milling 2 Glucose solution is added to the powder, wherein the glucose is 10g. At the same time, 280 grams of stainless steel metal grinding balls (ball-to-material ratio is 20:1) are put into a 250ml stainless steel grinding tank; The time is 30h.

[0060] (3) the mixture obtained in step (2) is dried in an oven, a...

Embodiment 3-4

[0065] In Examples 3 and 4, except SnS 2 Except that the mass ratio of powder and glucose is different from Example 2, other steps are all the same as Example 2, and the SnS of Example 3 and 4 2 The mass ratio of powder and glucose is shown in Table 1, and the SnS 2 See also Table 1 for the mass ratio to C. The performance test of the composite material was carried out in the same manner as in Example 1, and the performance results are shown in Table 1.

[0066] The relevant data sheet of table 1 embodiment 3-4

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com