Wet etching protection clamp free of damage to wafer

A technology for wet etching and protecting fixtures, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of small stress in the sealing part, wafer splintering, and troublesome use, so as to avoid damage to the wafer and avoid splintering. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

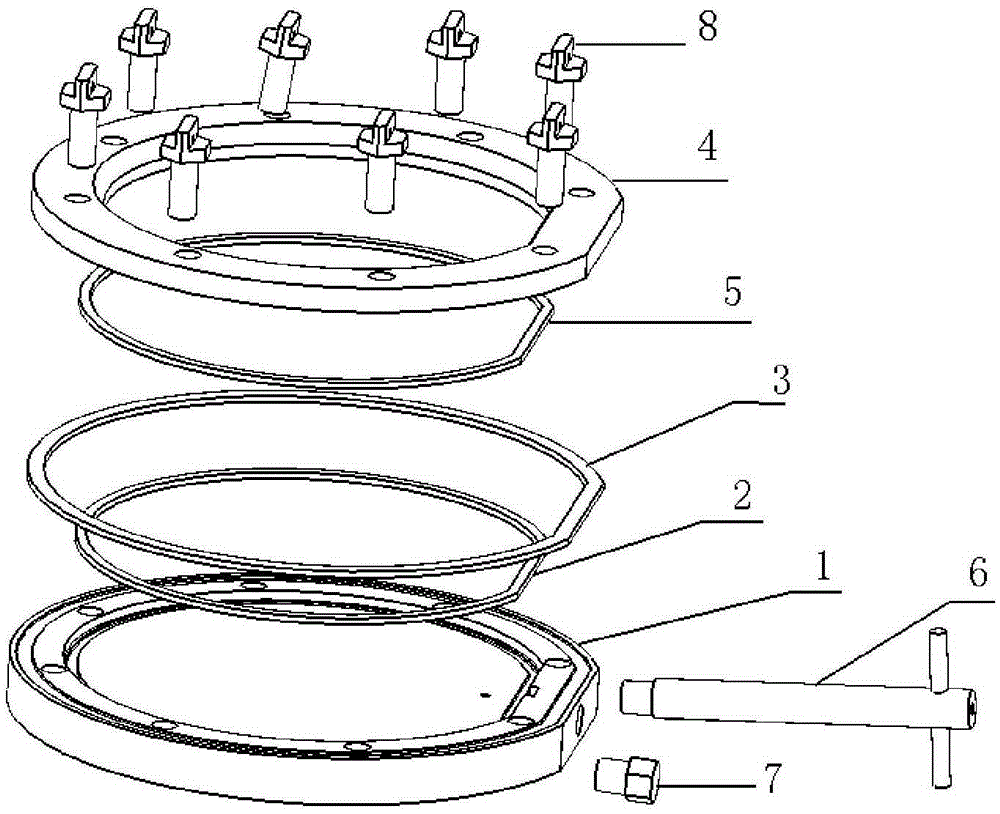

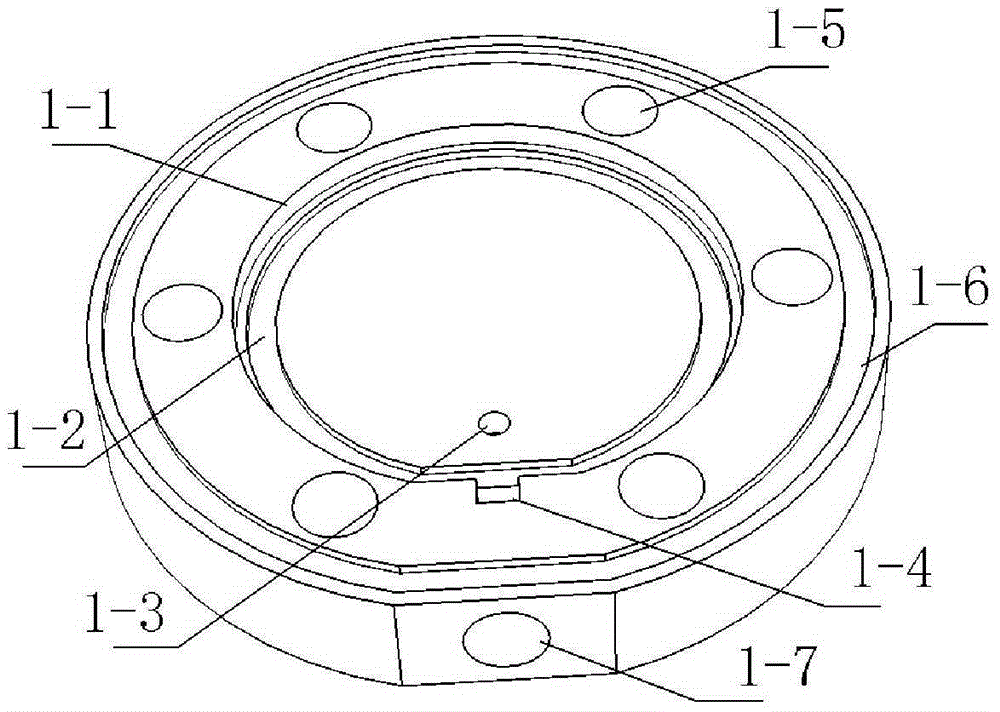

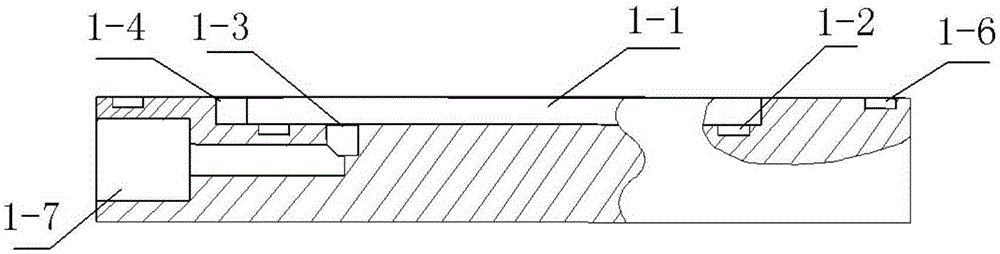

[0049] Such as figure 1As shown, a non-destructive wafer wet corrosion protection fixture includes a base 1 and a top cover 4 that cooperate with each other to clamp the wafer. The wafer includes a front side to be protected and a back side to be corroded, and the base accommodates And sealing and wrapping the front side, the top cover 4 is ring-shaped and presses against the edge of the back side, and both the base 1 and the top cover 4 are in contact with the wafer through an elastic buffer seal.

[0050] The non-destructive wafer corrosion protection jig has the advantages of low cost, convenient use, good sealing performance and no damage to the wafer. Its structure specifically includes a base 1 , a lower seal 2 , a balance washer 3 , a top cover 4 , an upper seal 5 , a ventilation handle 6 , a seal plug 7 and bolts 8 .

[0051] Such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com