A three-axis fiber optic gyroscope structure with eight-point vibration reduction and heat preservation measures

A technology of fiber optic gyroscopes and gyroscopes, which is applied in Sagnac effect gyroscopes, gyroscopes/steering sensing equipment, instruments, etc., can solve the problems of restricting the mechanical adaptability of inertial measurement devices, low anti-vibration characteristics of added meters, Increase the power consumption of the inertial measurement device and other issues to achieve the effect of avoiding the coupling of linear vibration and angular vibration, uniform deformation, and reducing the heating time of starting up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

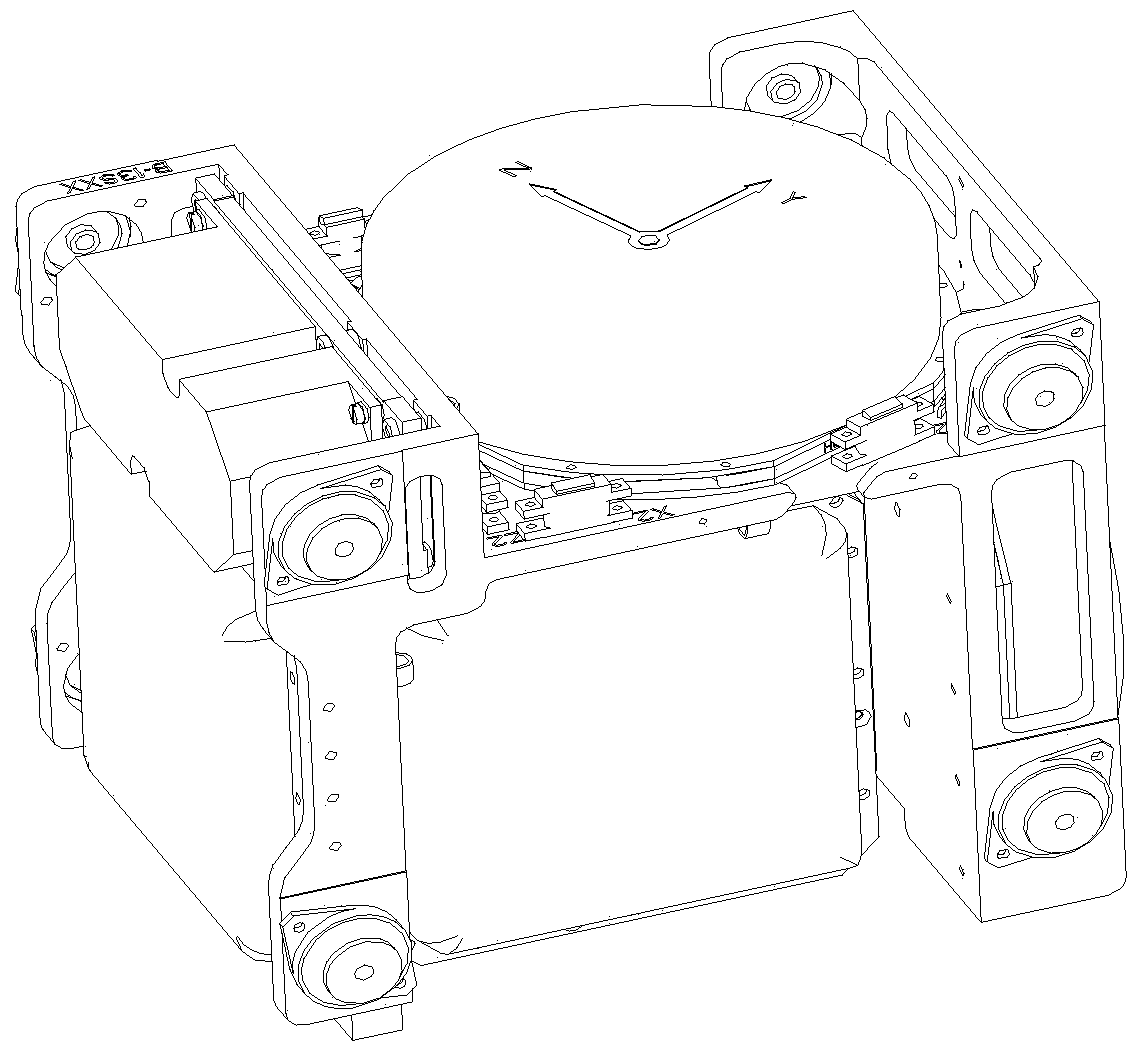

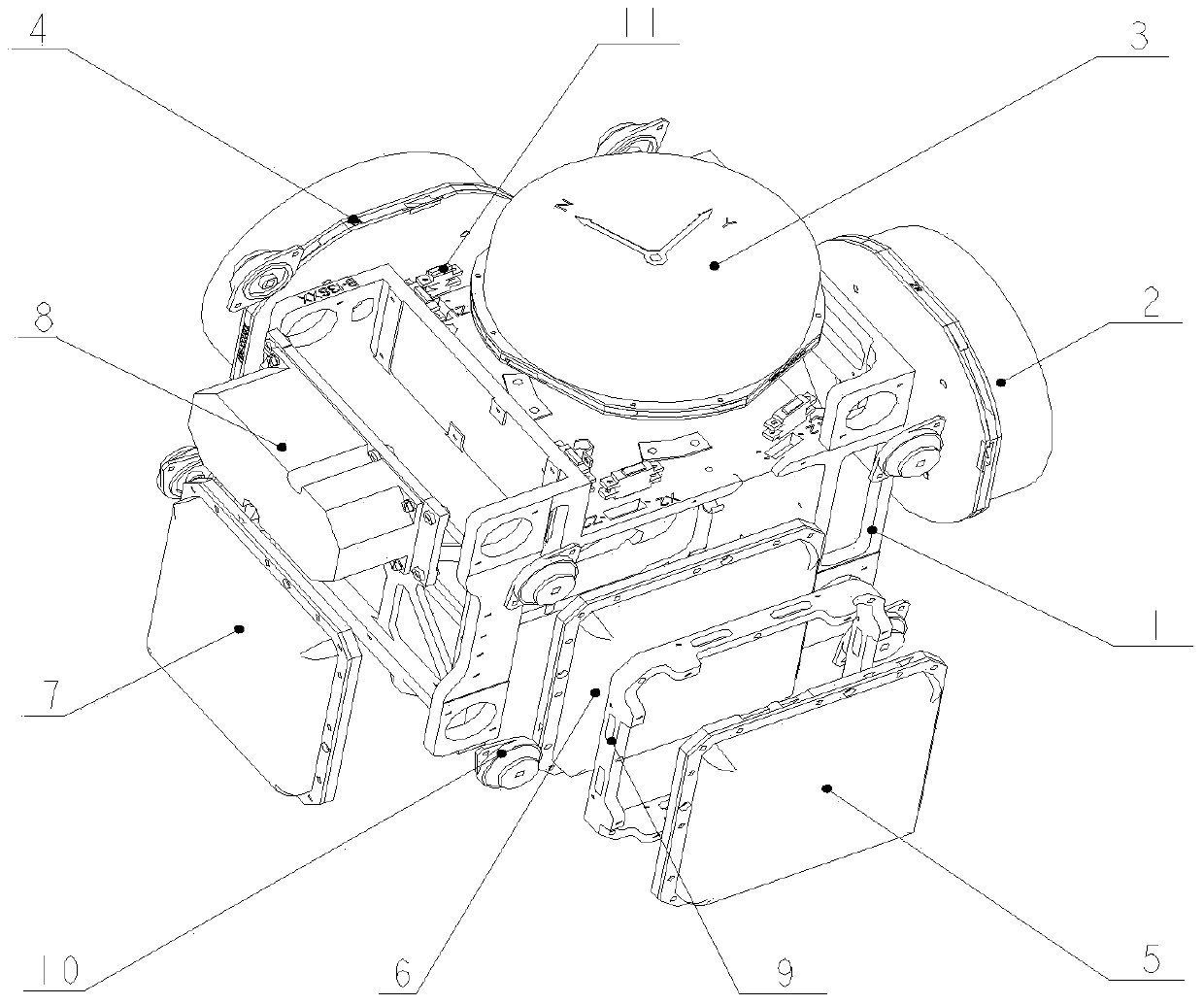

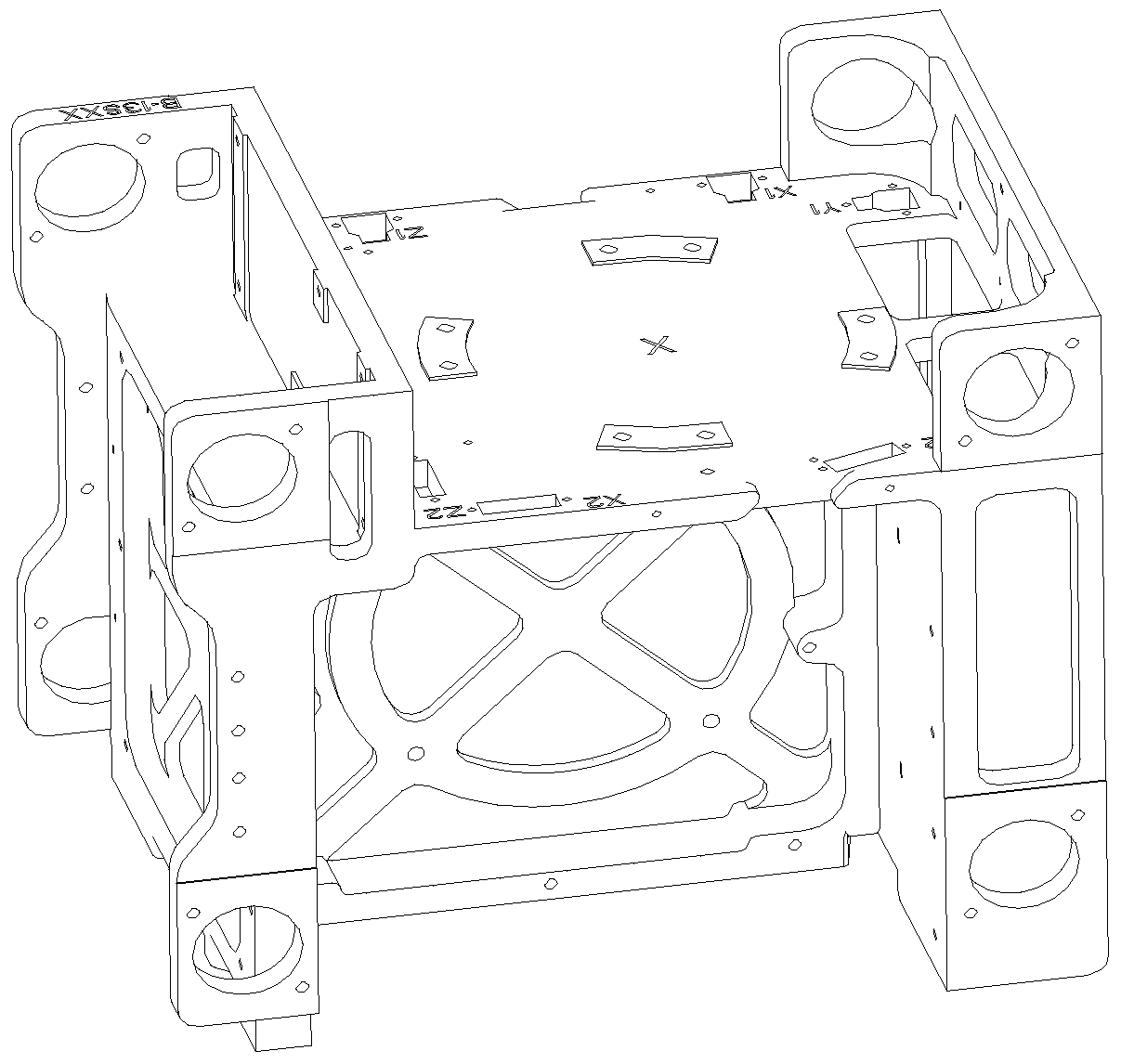

[0029] Such as figure 1 with 2 Shown, a three-axis fiber optic gyroscope structure, including a body 1, a first gyroscope 2, a second gyroscope 3, a third gyroscope 4, a first circuit box 5, a second circuit box 6, and a third circuit box 7 , plus meter assembly 8, shock absorber 10 and external connector 11; as image 3 As shown, the body 1 is a hexahedral frame, and the material is aluminum alloy 2A12. The first gyroscope 2, the third gyroscope 4 and the second gyroscope 3 are all fiber optic gyroscopes, and their positions are orthogonal and fixedly connected to the three surfaces of the body 1, and their axes are respectively x, y, For the z-axis, the shape and position tolerances of the perpendicularity of each pair are less than 0.05. The second gyroscope 3 is located on the top surface. The external connectors of the gyroscope component are placed in the top plane of the component for circuit connection with external devices. The first circuit box 5, the second cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com