Even acid distribution method for acidification of heterogeneous storage layer

A heterogeneous reservoir and uniform technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of frequent accidents, high cost, and laborious, etc., to improve permeability, avoid time-consuming, avoid The effect of large acid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The method proceeds as follows:

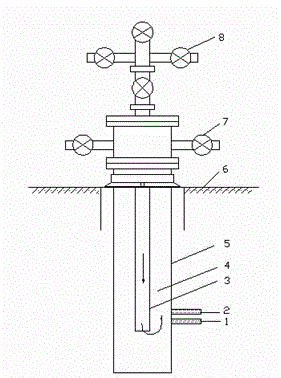

[0018] a. After running the acidizing string in the wellbore to the bottom of oil layer 1, circulate the high-permeability layer acidizing fluid containing flocculent temporary plugging materials to the middle of oil layer 2, then close the casing gate 7, and continue injecting into oil layers 1 and 2 ; The fluid for acidizing the hyperpermeable layer containing flocculent temporary plugging material is to take 0.8m according to the oil layer 1,2 per meter 3 For emulsified acid, add 0.5 tons of temporary plugging agent per meter of plugging layer into the emulsified acid, and mix well to obtain the acidification solution for hyperpermeable layer containing flocculent temporary plugging material;

[0019] b. When the pump pressure rises by 3MPa, control the displacement of the pump truck and inject 2.2m of emulsified acid required for acidification of the low-permeability layer according to 1 and 2 per meter of oil layer 3 ;

[0020] c...

Embodiment 2

[0024] The method proceeds as follows:

[0025] a. After running the acidizing string in the wellbore to the bottom of oil layer 1, circulate the high-permeability layer acidizing fluid containing flocculent temporary plugging materials to the middle of oil layer 2, then close the casing gate 7, and continue injecting into oil layers 1 and 2 ; The fluid used for acidizing the hyperpermeable layer containing flocculent temporary plugging material is to take 1.2m according to the oil layer 1,2 per meter 3 For emulsified acid, add 0.3 tons of temporary plugging agent per meter of plugging layer into the emulsified acid, and mix well to obtain the acidification solution for hyperpermeable layer containing flocculent temporary plugging material;

[0026] b. When the pump pressure rises by 5MPa, control the displacement of the pump truck and inject 1.8m of emulsified acid required for acidification of the low-permeability layer according to 1 and 2 per meter of oil layer 3 ;

[00...

Embodiment 4

[0038] Micellar acid is used to replace emulsifying acid, and the others are the same as in Examples 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com