Manufacturing method and application of standard reinforcing steel bar machining field capable of being utilized repeatedly

A production method and steel bar processing technology, applied in industrial buildings, substation rooms, etc., can solve the problems of inconvenient steel bar processing sheds and steel bar storage yards, unsightly erection, and non-recyclable use, so as to save economic expenses and reduce engineering costs , to avoid the effect of component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The manufacturing method of the reusable standardized steel bar processing shed of the present invention comprises the following steps:

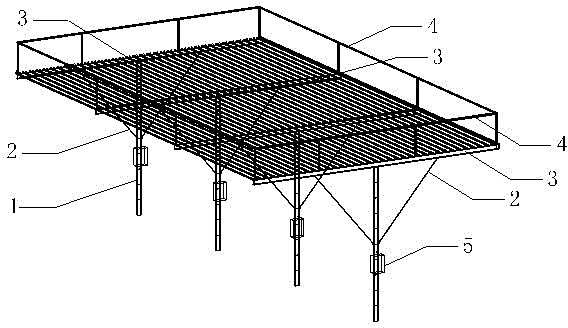

[0043] figure 1 It is a structural schematic diagram of a standardized steel bar processing shed according to an embodiment of the present invention.

[0044] a. Prefabricated steel bar processing shed column

[0045] Use 4 long 4m channel steels with a certain distance from each other to stand upright on the ground as the column 1 of the steel bar processing shed;

[0046] b. Make the protective top cover of the steel bar processing shed

[0047] The protective top cover of the steel bar processing shed is a rectangular steel pipe frame welded by several steel pipes. Four channel steels are longitudinally welded on the bottom of the rectangular steel pipe frame as the supporting beam 3 of the rectangular steel pipe frame. The number of supporting beams 3 corresponds to the column 1. The rectangular steel pipe A steel pipe protecti...

Embodiment 2

[0058] Standardized steel bar material stacking frame manufacturing method of the present invention, comprises the following steps:

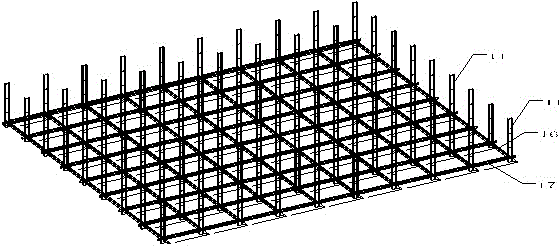

[0059] figure 2 It is a structural schematic diagram of a column in a standardized steel bar material stacking rack according to an embodiment of the present invention, image 3 It is a structural schematic diagram of a standardized steel bar material stacking frame according to an embodiment of the present invention.

[0060] a. Prefabricated reinforcement material stacking frame column

[0061]Prefabricate several channel steels 11 and several rectangular connecting plates of the same size, set two bolt connection holes 18 on the rectangular connecting plates, and weld and fix four rectangular connecting plates on the outside of the two legs and the inside of the waist of the channel steel 11 respectively by side welding. The outer side is made of steel bar material stacking frame columns, so that the columns can be extended and connected i...

Embodiment 3

[0074] Application of a reusable standardized steel bar processing yard in construction site transition. The method of the present invention is used in the steel bar project of the third phase (first bid section) of Taoshan Resettlement House in Bengbu. The construction method is simple, the control precision is high, the effect after installation is good, and the relevant requirements of the standardized construction site are met, and there is no damage on site. The steel structure materials used Reusable.

[0075] The present invention has substantive features and remarkable technical progress. The manufacturing method and application of the reusable standardized steel bar processing plant of the present invention make the whole construction site clean and beautiful, the steel bar materials are stacked in an orderly manner, and the steel bar materials are easy to take and use, and work efficiency is improved. , the effect is remarkable, and the steel structure materials used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com