Hard cord double-drum winding rubberizing device and production technology thereof

A glue sticking device and rope technology, which is applied to auxiliary equipment for rope making, textiles, papermaking, textile cables, etc., can solve the problems of waste of raw materials, difficulty in winding and forming hard ropes, and difficulty in sticking glue on the inner surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

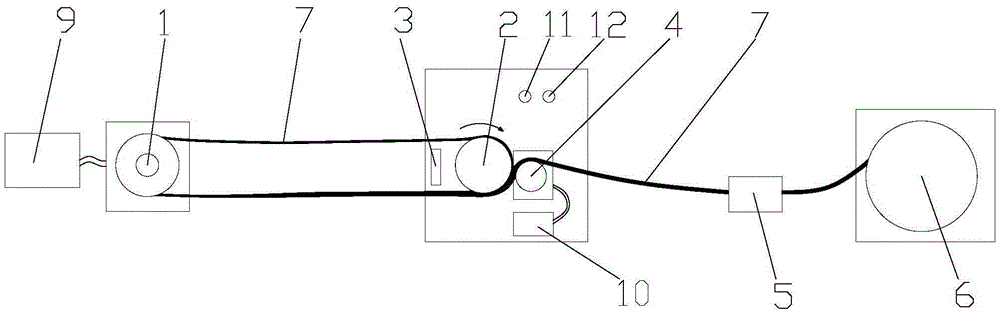

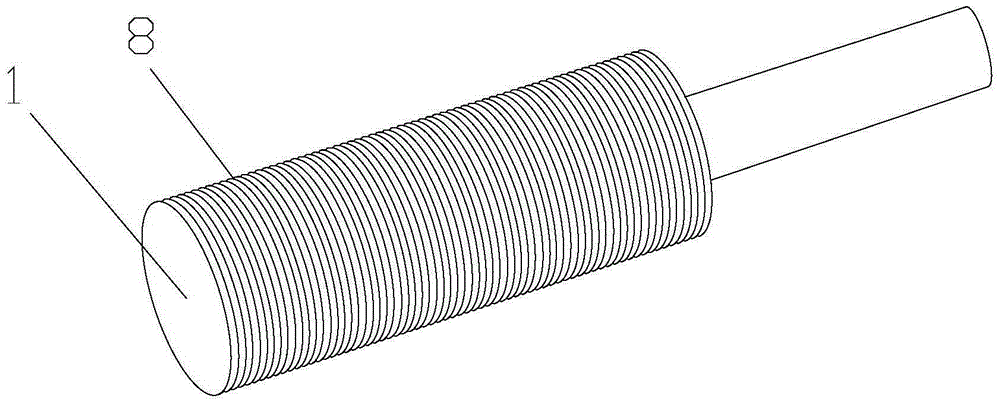

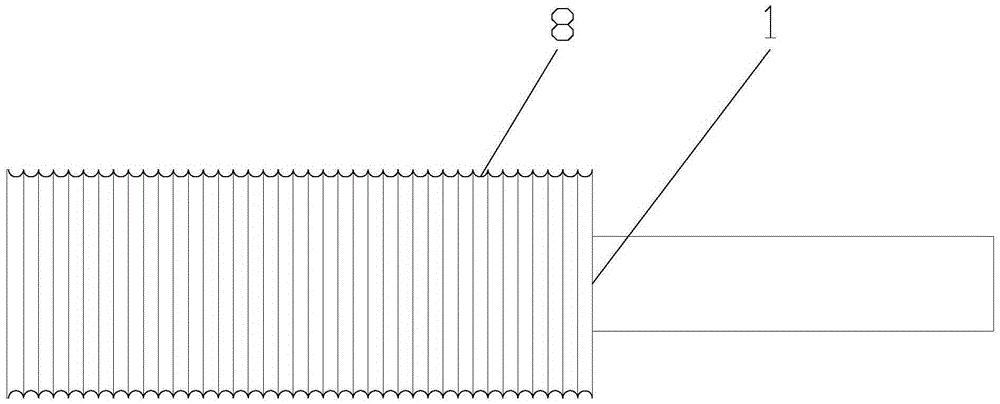

[0018] Such as Figure 1~3 Shown is a double-drum winding and gluing device for a hard wire rope, which is mainly composed of a wire drum 1, a light drum 2, a cutter 3, an attachment drum 4, a rubber material box 5, a wire rope loop 6 and a wire rope 7; The rope ring 6 is wound with a wire rope 7, the output end of the wire rope ring 6 is connected to the input end of the rubber material box 5 through the wire rope 7, and the output end of the rubber material box 5 is connected with the input end of the drum 4 through the wire rope 7, and the optical drum 2 is connected clockwise with the silk drum 1 through the wire rope 7; the cutter 3 is set between the optical drum 2 and the silk drum 1, the attachment drum 4 is set outside the optical drum 2, and the side wall of the silk drum 1 is in the direction of the shaft end There are multiple semicircular grooves 8 connected end to end.

[0019] Wherein the depth of the semicircular groove 8 is 40%-60% of the diameter of the wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com