Automatic soldering furnace

A tin dipping furnace, automatic technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of large fluctuations in the surface of tin liquid and difficult control of the length of tin dipping, etc., to achieve good tinning effect, Good soldering effect and small vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

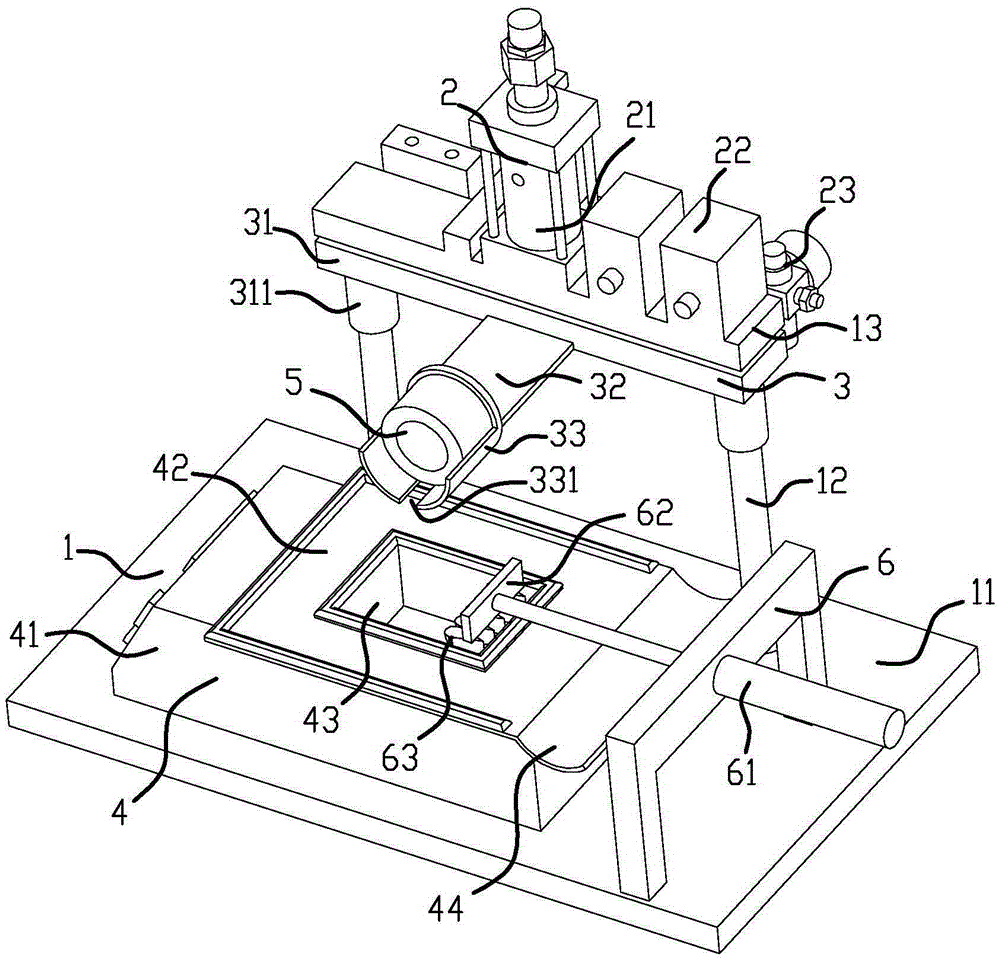

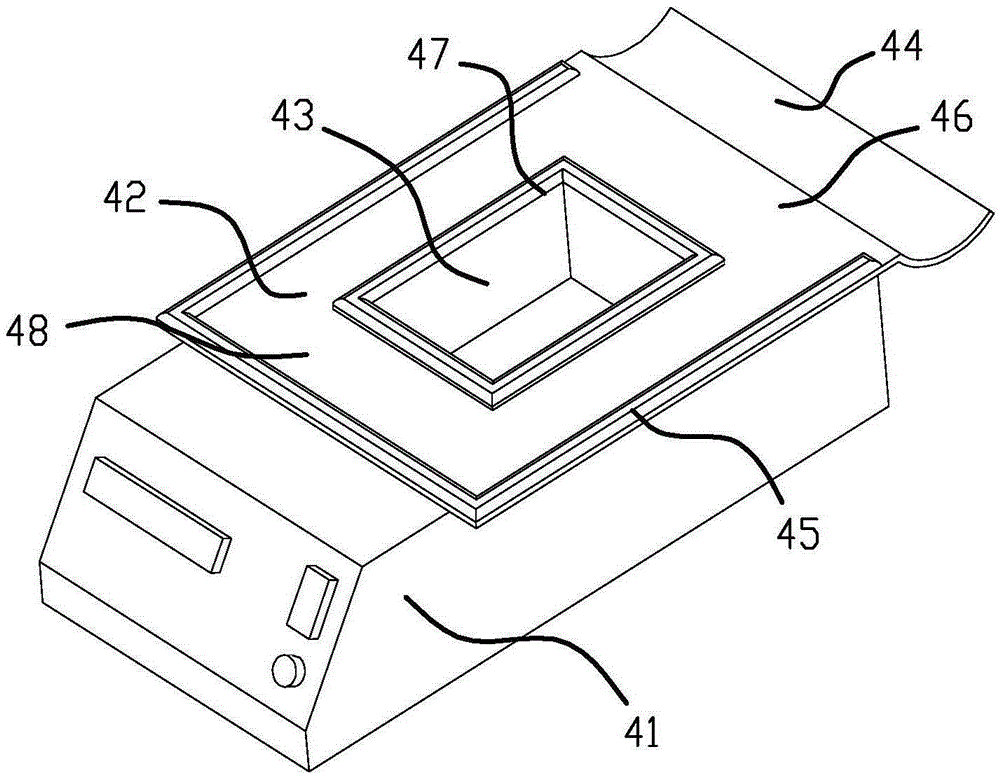

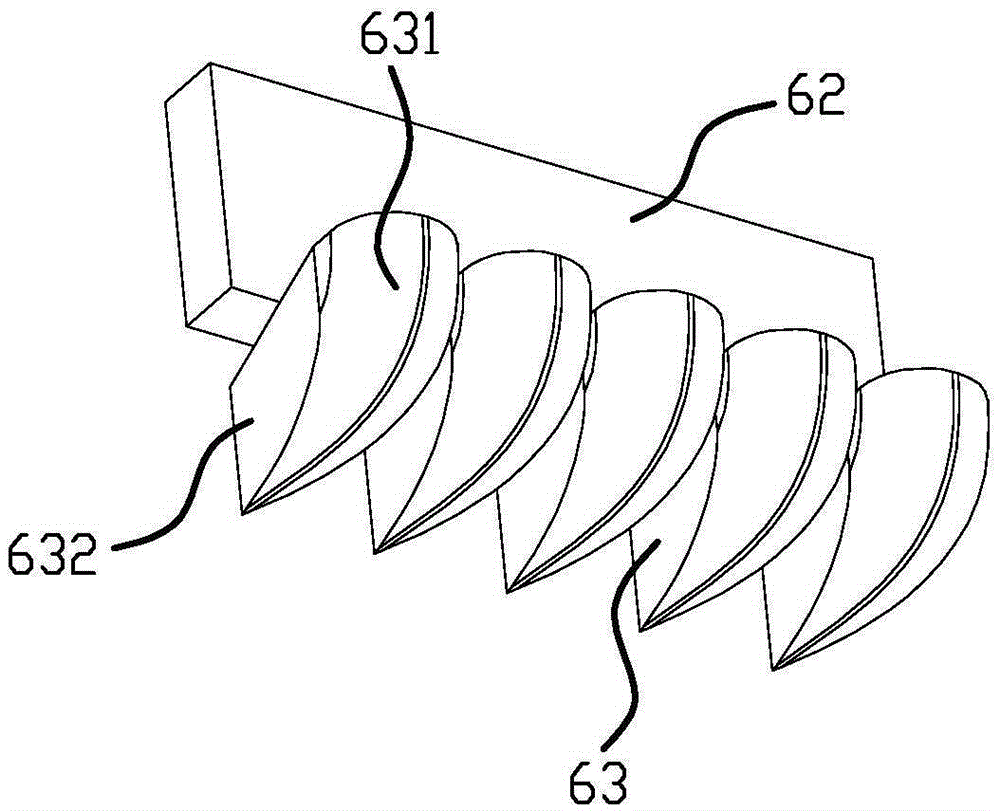

[0031] Such as figure 1 with figure 2 As shown, the automatic tin immersion furnace includes a frame 1, a telescopic mechanism 2, a mechanical arm 3, and a tin immersion furnace 4. The telescopic mechanism 2 is installed on the frame 1, and the mechanical arm 3 is connected to the output shaft of the telescopic mechanism 2. The workpiece 5 is clamped on the robot arm 3, the immersion tin furnace 4 is installed on the frame 1, and the immersion tin furnace 4 is provided with an open melting chamber 43. The melting chamber 43 is filled with molten tin liquid, and the telescopic mechanism 2 The robot arm 3 is pushed to move, the workpiece 5 moves with the robot arm 3 and the soldered part of the workpiece 5 is immersed in the melting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com