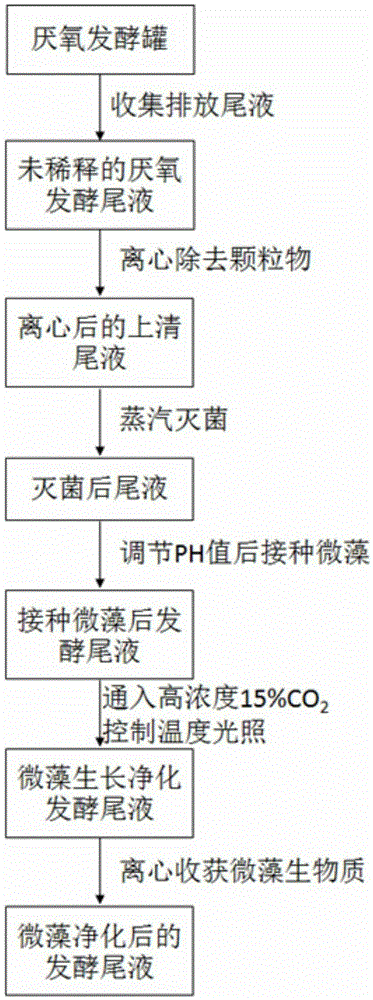

Method for purifying undiluted anaerobic fermentation tail liquid by growing microalgae in carbon dioxide environment

An anaerobic fermentation and carbon dioxide technology, applied in chemical instruments and methods, single-cell algae, multi-stage water treatment, etc., can solve the problems of algae growth inhibition, reactor volume increase, unfavorable photosynthesis, etc., and shorten growth lag period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Obtain the anaerobic fermentation tail liquid at the outlet discharge of the anaerobic fermentation tank with pig manure as the substrate. The COD content of the anaerobic fermentation tail liquid is 2000mg / L, centrifuge to remove suspended particles, and take the supernatant as raw material. The supernatant obtained after centrifugation was sterilized under saturated water vapor at 110° C. for 20 min. The pH of the tail liquid before sterilization was 7, and the pH of the tail liquid after sterilization was 9. Use 1mol / L sodium hydroxide and 1mol / L hydrochloric acid to adjust the pH to 6, take fresh natural Chlorella seed liquid, and inoculate it into the pH-adjusted tail solution according to the inoculum size of 0.1g / L. Under the condition of constant temperature of 25°C, light intensity of 5000lux, 12h of light and 12h of darkness every day, 30ml / min of high-concentration 15% carbon dioxide was passed into 300ml of anaerobic fermentation tail liquid and cultivated f...

Embodiment 2

[0031] Obtain the anaerobic fermentation tail liquid at the outlet discharge of the anaerobic fermentation tank with food waste as the substrate. The COD content of the anaerobic fermentation tail liquid is 3000mg / L, centrifuge to remove suspended particles, and take the supernatant as raw material. The supernatant obtained after centrifugation was sterilized under saturated water vapor at 115° C. for 25 min. The pH of the tail liquid before sterilization was 8, and the pH of the tail liquid after sterilization was 10. Use 1mol / L sodium hydroxide and 1mol / L hydrochloric acid to adjust the pH to 7, take the Nannochloropsis mutant liquid obtained by nuclear mutagenesis, and inoculate it into the tail liquid after adjusting the pH according to the inoculum size of 0.25g / L . At a constant temperature of 27.5°C, with a light intensity of 6000 lux, 12 hours of light and 12 hours of darkness every day, 45ml / min of high-concentration 15% carbon dioxide was introduced into the 300ml a...

Embodiment 3

[0033]The anaerobic fermentation tail liquid was obtained at the outlet discharge of the anaerobic fermentation tank with rice straw as the substrate. The COD content of the anaerobic fermentation tail liquid was 4000 mg / L, and the suspended particles were removed by centrifugation, and the supernatant was used as a raw material. The supernatant obtained after centrifugation was sterilized under saturated water vapor at 120° C. for 40 min. The pH of the tail liquid before sterilization was 9, and the pH of the tail liquid after sterilization was 11. Use 1mol / L sodium hydroxide and 1mol / L hydrochloric acid to adjust the pH to 8, take the spirulina seed liquid obtained through genetic modification, and inoculate it into the tail liquid after pH adjustment according to the inoculation amount of 0.5g / L. At a constant temperature of 30°C, with a light intensity of 7000 lux, 12 hours of light and 12 hours of darkness every day, 60ml / min of high-concentration 15% carbon dioxide was i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com