Methanol gasoline efficient composite additive and preparation method thereof

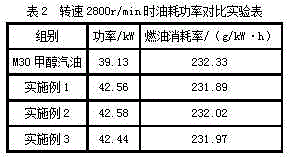

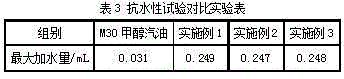

A compound additive, methanol gasoline technology, used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve problems such as poor water resistance, reduce combustion emissions, etc., and achieve the effects of improving power, reducing fuel consumption, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: (1) After mixing 9 kg of diethyl alcohol formal, 6 kg of tert-butyl methyl ether, and 1.2 kg of isooctyl phosphate (RP-98), stir with a magnetic stirrer for 3 to 4 minutes, and then add the average particle size 1.8 kg of 30nm nano-cobalt ferrite and 1.6 kg of n-heptane were ultrasonically dispersed at 56-60°C for 60-80 minutes with an ultrasonic disperser;

[0020] (2) After mixing 6 kg of propylene glycol butyl ether, 4.5 kg of cocoic acid diethanolamide (6501), 1.1 kg of isotridecyl stearate, and 2.5 kg of sodium lauroyl sarcosinate, stir with a magnetic stirrer for 5-8 minutes ;

[0021] (3) After mixing the mixture in step (1) and the mixture in step (2), stir with a magnetic stirrer for 3-4 minutes, and then ultrasonically disperse at 52-55°C for 60-80 minutes to obtain the product. When in use, the methanol-gasoline high-efficiency composite additive of the present invention is directly added to the methanol-gasoline in an amount of 600-800 mg / L.

Embodiment 2

[0022] Example 2: (1) After mixing 8 kg of diethyl alcohol formal, 5 kg of tert-butyl methyl ether, and 1 kg of isooctyl phosphate (RP-98), stir with a magnetic stirrer for 3 to 4 minutes, and then add the average particle size 1.5 kg of 30nm nano-cobalt ferrite and 1.5 kg of n-heptane, ultrasonically disperse at 56-60°C for 60-80 min with an ultrasonic disperser;

[0023] (2) After mixing 5 kg of propylene glycol butyl ether, 4 kg of cocoic acid diethanolamide (6501), 1 kg of isotridecyl stearate, and 2 kg of sodium lauroyl sarcosinate, stir with a magnetic stirrer for 5-8 minutes ;

[0024] (3) After mixing the mixture in step (1) and the mixture in step (2), stir with a magnetic stirrer for 3-4 minutes, and then ultrasonically disperse at 52-55°C for 60-80 minutes to obtain the product. When in use, the methanol-gasoline high-efficiency composite additive of the present invention is directly added to the methanol-gasoline in an amount of 600-800 mg / L.

Embodiment 3

[0025] Example 3: (1) After mixing 10 kg of diethyl alcohol formal, 7 kg of tert-butyl methyl ether, and 1.5 kg of isooctyl phosphate (RP-98), stir with a magnetic stirrer for 3 to 4 minutes, and then add the average particle size 2 kg of 30nm nano-cobalt ferrite and 2 kg of n-heptane, ultrasonically disperse at 56-60°C for 60-80 minutes with an ultrasonic disperser;

[0026] (2) After mixing 7 kg of propylene glycol butyl ether, 5 kg of cocoic acid diethanolamide (6501), 1.5 kg of isotridecyl stearate, and 3 kg of sodium lauroyl sarcosinate, stir with a magnetic stirrer for 5-8 minutes ;

[0027] (3) After mixing the mixture in step (1) and the mixture in step (2), stir with a magnetic stirrer for 3-4 minutes, and then ultrasonically disperse at 52-55°C for 60-80 minutes to obtain the product. When in use, the methanol-gasoline high-efficiency composite additive of the present invention is directly added to the methanol-gasoline in an amount of 600-800 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com