Pyrolysis reactor

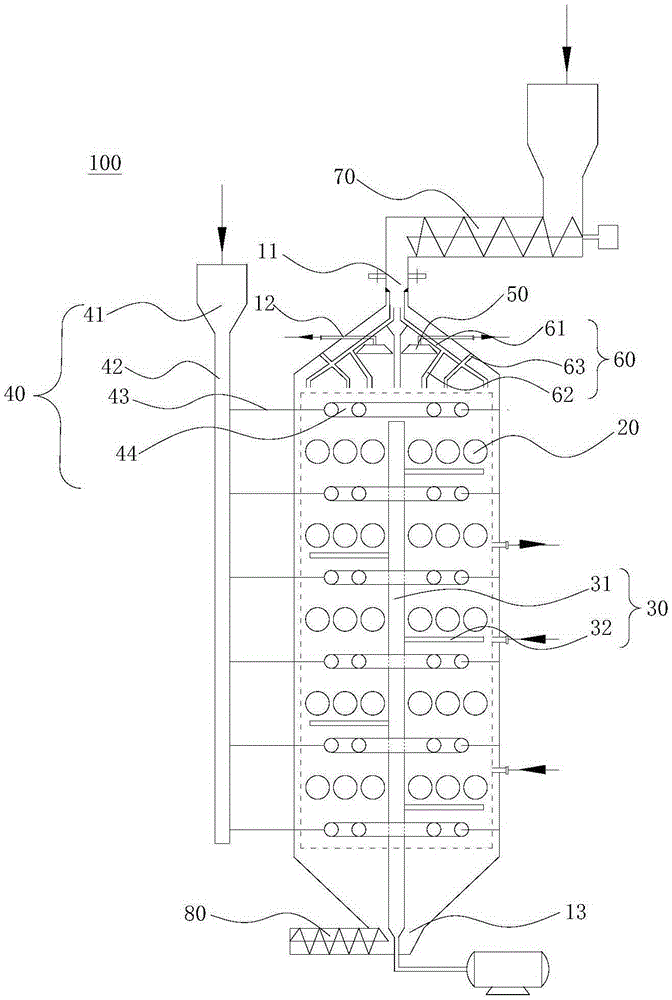

A technology of pyrolysis reactor and regenerative radiant tube, which is applied in coke oven heating, indirect heating dry distillation, petroleum industry, etc., can solve problems such as difficult promotion and demonstration, separation, and huge condensation recovery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Low-order bituminous coal particle size 1 ~ 5mm

[0080]

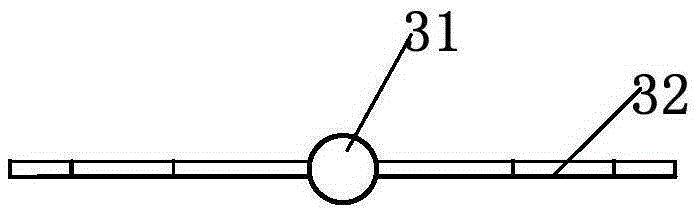

[0081] 1) The stirring rod adopts scheme a, that is, the angle between the upper and lower layers of stirring rods is 180°;

[0082] 2) The radiant tube in the pyrolysis reactor is a circular radiant tube with DN200mm, and the distance between the left and right centers of the radiant tube is 300mm. The vertical center spacing is 400mm. The laying pipe layer is 18 layers, and the reactor width is 2.9m;

[0083] 3) The pyrolysis distributor has 4+1 primary outlets, each of which is provided with 3 secondary discharge channels, and each secondary discharge channel is provided with 3 tertiary discharge channels;

[0084] 4) The catalyst with a particle size of 0.5mm passes through the catalyst main pipe, branch pipe and catalyst nozzle, sprays into the interior of the pyrolysis furnace, and mixes evenly with the carbonaceous material;

[0085] 5) Control the temperature of the upper part of the pyrolysis furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com